Sealed LED light strings are common in holiday displays, landscape lighting, and indoor decor. Unlike older, replaceable-bulb designs, these units often come with LEDs permanently embedded in a continuous circuit. When one bulb fails, it can disrupt the entire string—especially if the design uses a series circuit. Cutting the wire may seem like the only solution, but it compromises waterproofing, voids warranties, and increases future failure risks. Fortunately, there are smarter, non-invasive ways to diagnose and repair a faulty LED without breaking the seal.

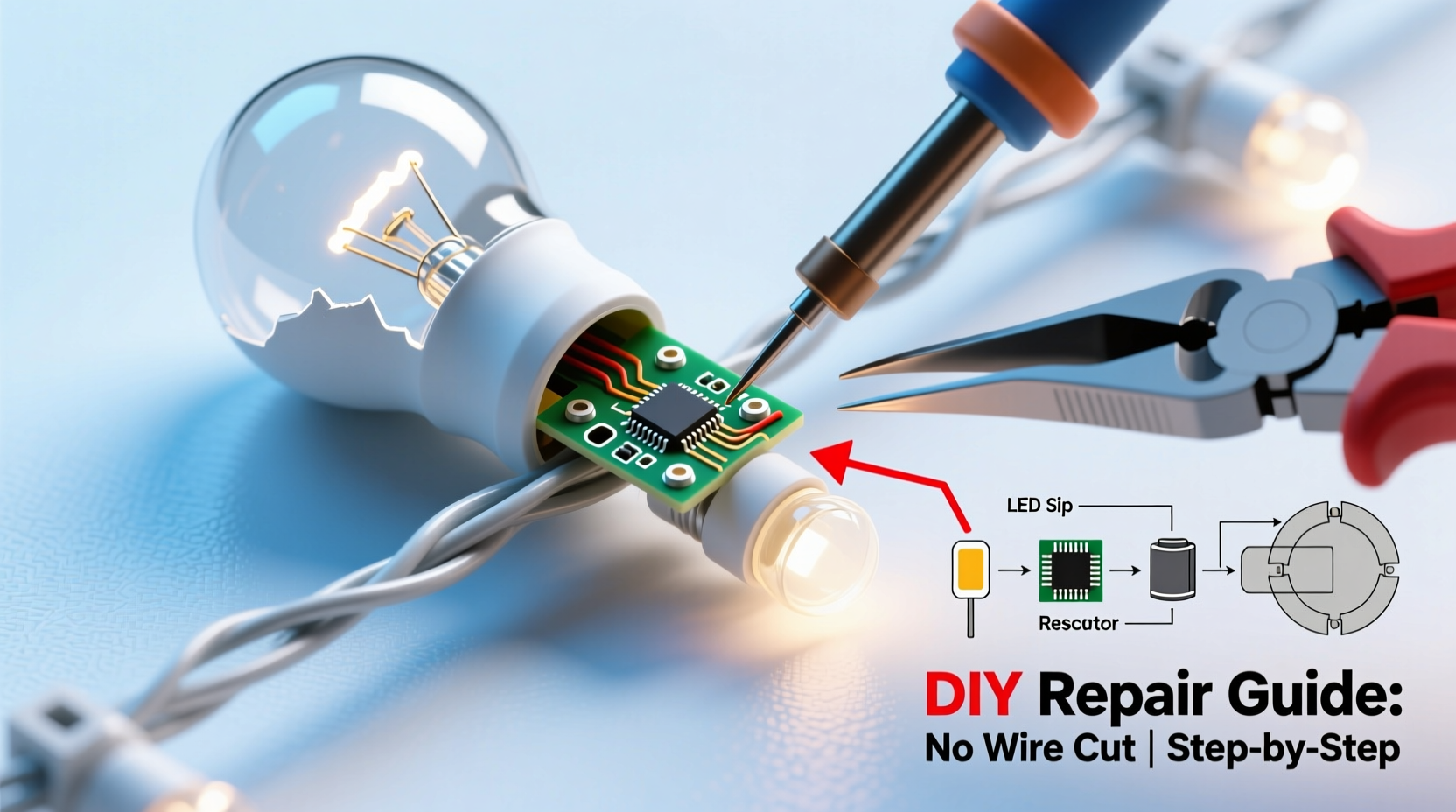

This guide walks through proven techniques for identifying and addressing LED failures in sealed strings, preserving both function and longevity. Whether you're troubleshooting seasonal decorations or permanent outdoor fixtures, these strategies will help you restore light safely and efficiently.

Understanding Sealed LED Light Strings

Sealed LED light strings are engineered for durability and weather resistance. The bulbs are typically mounted on a flexible printed circuit board (PCB) strip and encased in silicone or rubber sheathing. This construction protects against moisture, dust, and physical damage. However, because the components aren't user-serviceable by design, many assume that any failure means full replacement.

The reality is more nuanced. While individual LEDs can’t be swapped like traditional bulbs, the root cause of a dark section isn’t always the LED itself—it could be a failed solder joint, a micro-fracture in the trace, or a voltage drop due to corrosion at a connection point. Recognizing this distinction opens the door to targeted fixes without cutting wires.

“Most sealed LED failures occur not at the diode, but at the interface points—connections, bends, or stress zones.” — Rajiv Mehta, Electrical Systems Engineer, SmartLume Technologies

Step-by-Step Diagnosis Without Wire Cutting

Before attempting repairs, confirm the nature and location of the fault. A systematic approach prevents unnecessary interventions and ensures accuracy.

- Visual Inspection: Examine the entire length under bright light. Look for discoloration (brownish spots), bulges in the casing, or visible cracks near LED nodes. These often indicate overheating or physical trauma.

- Power Test: Plug in the string and observe behavior. Do all LEDs go out? Does a segment flicker? Use a known working power source to rule out outlet issues.

- Segment Mapping: Note where the last functioning LED appears and the first dead one begins. Many sealed strings group LEDs in clusters of 3–6 powered in parallel across a series line. Failure in one cluster can affect downstream sections if the shared rail is interrupted.

- Voltage Check (if accessible): If end connectors allow probe access, use a multimeter set to DC volts. Measure input voltage at the beginning and suspected break point. A significant drop indicates an open circuit upstream.

- Continuity Scan: With the unit unplugged, test continuity along the positive and negative rails between live and dead zones. No continuity suggests a trace break or disconnected node.

Non-Invasive Repair Techniques

Once the problem area is identified, consider these wire-preserving solutions.

1. Thermal Reset for Shunted LEDs

Some modern LED strings use “shunted” diodes designed to bypass a failed LED automatically. But occasionally, the shunt doesn’t activate due to low current or oxide buildup. Applying controlled heat can trigger the fail-safe mechanism.

- Use a hairdryer on low heat, held 6 inches from the suspect LED for 30–45 seconds.

- Do not exceed 150°F (65°C)—overheating damages encapsulation.

- Reconnect and test. Repeat once if needed.

This method works best on newer, commercially produced strings with built-in redundancy.

2. External Bypass Using Conductive Epoxy

If testing confirms a dead LED or broken trace, you can create an external bridge over the faulty section without cutting wires.

- Clean the area around the failed LED with isopropyl alcohol and a cotton swab.

- Using a fine-tipped applicator, apply conductive epoxy (e.g., MG Chemicals 8331) across the two contact points of the dead LED—effectively shorting it out.

- Allow 12–24 hours for full cure, depending on product specs.

- Test the string. If successful, the circuit should now route current around the failed component.

This technique mimics replacing a blown fuse—by removing the high-resistance node, the rest of the circuit regains continuity.

| Method | Tools Needed | Success Rate | Risk Level |

|---|---|---|---|

| Thermal Reset | Hairdryer, gloves | ~40% | Low |

| Conductive Epoxy Bypass | Epoxy, swabs, tweezers | ~75% | Moderate |

| Magnetic Pulse Detection* | EM sensor, amplifier | Diagnostic only | Negligible |

*Advanced method: Detects current flow via electromagnetic field; useful for pinpointing live vs. dead zones without direct contact.

3. Inductive Voltage Boosting (For Long Runs)

In long sealed strings, voltage drop can mimic LED failure. A booster module inserted at the midpoint can compensate without modifying wiring.

- Choose a DC voltage booster compatible with your system (typically 12V or 24V).

- Mount externally using adhesive-backed clips.

- Connect via magnetic pickup coils or clamp-on terminals that draw power inductively.

This won’t fix a true open circuit but can revive dim or unresponsive segments caused by insufficient power delivery.

Troubleshooting Common Scenarios

Different symptoms call for different responses. Here’s how to match strategy to situation.

Scenario: One LED is Dark, Rest Are Bright

Modern parallel-grouped strings often tolerate single-diode failure. If only one is off and others shine normally, the issue may resolve itself after thermal cycling (unplugging overnight). If not, apply conductive epoxy to bypass the node.

Scenario: Half the String Is Dead

This usually indicates a trace fracture at a flex point—common near plug ends or mounting brackets. Perform continuity tests across suspected areas. If a break is confirmed, apply conductive epoxy across the gap on the surface of the casing (after cleaning).

Mini Case Study: Reviving a Patio String Light

Sarah in Portland had a 24-foot sealed LED string along her deck railing. After winter, the last 8 feet went dark. She tested voltage at the transition point—only 1.2V instead of 12V. Assuming a break, she cleaned the casing near a bend where snow had piled up. Applying conductive epoxy across the seam restored 11.8V downstream. The full string lit again. No wires were cut, and waterproofing remained intact.

Her success highlights the importance of diagnosing before acting—and shows how minor interventions can yield major results.

Checklist: Fix a Broken LED Without Cutting Wires

Follow this sequence to maximize success while minimizing risk:

- ✅ Unplug the light string before inspection or handling.

- ✅ Visually scan for physical damage, discoloration, or stress points.

- ✅ Confirm power supply functionality with a tester or known-good string.

- ✅ Identify the last illuminated and first dark LED.

- ✅ Use a multimeter to check voltage and continuity at key junctions.

- ✅ Attempt thermal reset with a hairdryer (low heat, 30 sec).

- ✅ Apply conductive epoxy across contacts of the failed LED if thermal reset fails.

- ✅ Allow full cure time before retesting.

- ✅ Consider inductive boosting for long runs with voltage drop.

- ✅ Document the repair location for future reference.

What Not to Do: Common Mistakes

Avoid these pitfalls that worsen the problem or create safety hazards.

| Don’t | Why | Do This Instead |

|---|---|---|

| Use regular glue or tape to “fix” connections | Non-conductive; provides no electrical path | Use certified conductive epoxy |

| Apply excessive heat with a lighter or soldering iron | Melts casing, destroys traces, fire risk | Use low-heat dryer or warm air gun |

| Cut the wire “just to see” | Breaks seal, invites moisture, hard to repair cleanly | Diagnose non-invasively first |

| Ignore manufacturer warranty | Voiding it unnecessarily increases long-term cost | Contact support for eligible replacements |

“Preserving the integrity of the seal is often more important than fixing the immediate fault. Moisture ingress kills more LED strings than bulb failure.” — Lena Torres, Product Durability Analyst, EcoGlow Lighting

Frequently Asked Questions

Can I replace a single LED in a sealed string?

No—not practically. The LEDs are surface-mounted and sealed within a waterproof jacket. Removing one requires peeling back layers, which destroys the enclosure. Instead, bypass the failed unit electrically using conductive epoxy.

Will bypassing a dead LED make the rest brighter?

No. LEDs in sealed strings are usually arranged in parallel groups fed by a constant-voltage supply. Removing one load slightly reduces total draw, but brightness remains stable due to regulated drivers. You may notice a marginal efficiency gain, but no visible change in output.

How long will a conductive epoxy repair last outdoors?

High-quality conductive epoxies withstand outdoor conditions for 2–5 years when applied correctly. Protect the patch from direct UV exposure with a small piece of self-fusing silicone tape if possible. Avoid locations prone to constant water pooling.

Final Thoughts and Next Steps

Fixing a broken LED in a sealed light string without cutting the wire is not only possible—it’s often the smarter, longer-lasting choice. By combining careful diagnosis with precise, non-destructive techniques, you extend the life of your lighting investment and reduce electronic waste.

The key is patience: take time to understand the circuit layout, verify the fault, and choose the least invasive solution. Whether it’s a simple heat reset or a strategic epoxy bypass, each repair contributes to a more sustainable approach to home electronics.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?