LED light strings are popular for holiday decor, patio ambiance, and indoor accent lighting due to their energy efficiency and long lifespan. But when one or more bulbs fail, the entire section—or sometimes the whole string—can go dark. Unlike incandescent bulbs, LEDs don’t burn out in the traditional sense; they may flicker, dim, or stop working due to loose connections, voltage drops, or internal semiconductor failure. The challenge arises when you need to identify which specific bulb is faulty—but don’t have a multimeter or specialized tester on hand. Fortunately, several practical, low-tech methods exist to isolate and test individual LED bulbs using only household items and observational techniques.

Understanding LED String Behavior

Before attempting any diagnostic method, it's essential to understand how most LED strings are wired. Many modern LED light sets use a series-parallel configuration: groups of LEDs are wired in series, and these groups are connected in parallel across the power supply. This means that if one LED in a series group fails open (a common failure mode), the entire segment will go dark—even if the rest of the bulbs are functional.

This differs from older incandescent strings, where a single dead bulb could be spotted by visual inspection or using a continuity tester. LEDs, being solid-state devices, often fail without visible signs like broken filaments. Their small size and sealed design make internal diagnostics impossible without tools—yet their behavior within the circuit offers clues.

“Most LED failures in decorative strings are due to poor solder joints or thermal stress, not the diode itself. Often, the issue isn’t the bulb but its connection.” — Rafael Nguyen, Electrical Technician with 15 years in consumer lighting repair

Visual Inspection and Physical Testing

The first step in diagnosing an LED string doesn't require any tools at all—just sharp eyes and careful handling. Begin by unplugging the lights and examining each bulb closely under bright light.

- Look for discoloration: A brownish or blackened lens may indicate overheating or electrical arcing.

- Check for looseness: Gently wiggle each bulb in its socket. If it moves excessively or feels unseated, it may not be making proper contact.

- Inspect the base: Some LED bulbs have slightly bent or corroded metal bases that prevent conduction.

- Examine the socket: Cracked, warped, or melted plastic around the socket suggests damage that could interrupt the circuit.

If you find a suspect bulb, try removing it and reinserting it firmly. Sometimes, simply reseating the bulb restores the connection. For wedge-base LEDs commonly used in light strings, rotate the bulb slightly as you push it in—this can help clean minor oxidation off the contacts.

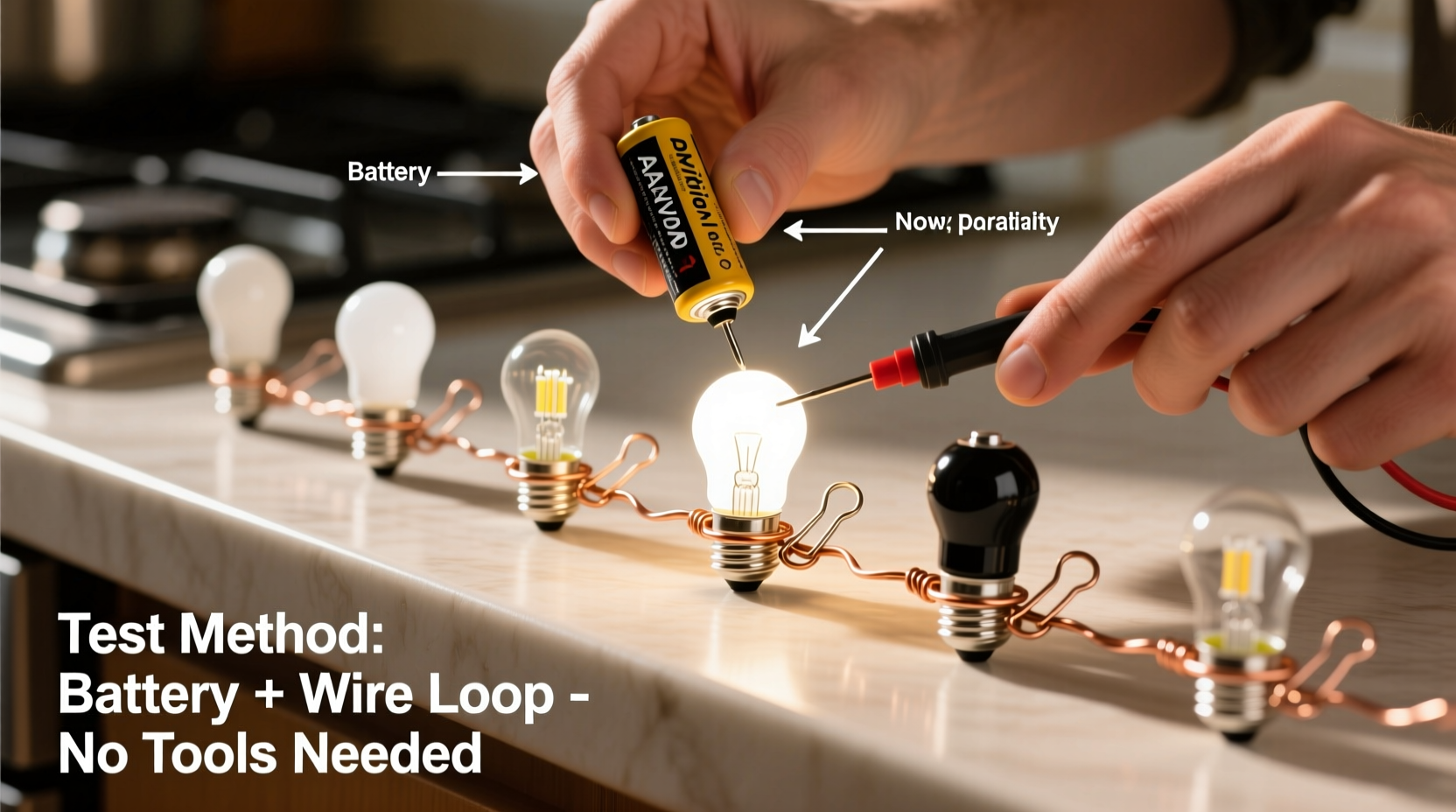

Testing Methods Without Tools

When visual inspection doesn’t reveal the culprit, systematic testing becomes necessary. The following methods rely on observation, substitution, and basic circuit principles—all without requiring a multimeter or continuity checker.

1. The Swap Test

This method uses known-good bulbs to isolate faults through replacement. It’s especially effective if only one or two bulbs are out in an otherwise working string.

- Unplug the light string.

- Select a bulb from a fully lit section of the same string (or a matching spare).

- Remove the suspect bulb and insert the known-good one in its place.

- Plug in the string and observe.

- If the section now works, the original bulb was faulty. If not, the issue may lie in the socket or wiring.

- Repeat with other dark bulbs, using only tested-good replacements.

Keep track of which bulbs you’ve swapped. Label them with tape if needed. This prevents confusion and helps map problem areas.

2. The Shadow or Reflection Method

In complete darkness, plug in the light string and watch each LED carefully. Even a bulb that appears “dead” may emit a faint glow or flicker imperceptible in ambient light. This subtle emission indicates that the bulb is receiving some voltage but may be failing internally or operating below threshold.

Use a white wall or reflective surface behind the lights to amplify visibility. Move slowly along the string, observing each LED for micro-flickers or dim pulses. A bulb that flickers erratically while others remain steady is likely compromised.

3. The Tap Test

Gently tap each suspect bulb and its socket with a non-conductive object like a plastic pen or chopstick while the string is powered. Listen for changes in sound—like a brief pop or flicker—and watch for sudden illumination.

A responsive flicker during tapping suggests a loose connection, cracked solder joint, or intermittent break inside the bulb. These are common in lights exposed to weather, vibration, or frequent coiling/uncoiling.

“I’ve revived dozens of ‘dead’ LED strings just by tapping the base of dim bulbs. It’s not a fix, but it tells me exactly where to focus repairs.” — Dana Reeves, Home Automation Enthusiast and DIY Blogger

Segment Isolation Technique

For longer strings with multiple dark sections, divide and conquer. Most LED strings are designed so that every 10–50 bulbs form a functional block. If one block is out but others work, focus your testing there.

Begin at one end of the dead segment and swap bulbs sequentially from the nearest working section. Start with the first bulb adjacent to the live section—this position is often where voltage drop or connection failure begins.

If swapping doesn’t restore function, check the wire between segments. Look for pinched insulation, rodent damage, or kinks that might interrupt current flow. A break before the first bulb in a segment will prevent all downstream LEDs from lighting—even if they’re functional.

| Method | Best For | Limits |

|---|---|---|

| Swap Test | Single dark bulbs, available spares | Requires donor bulbs; time-consuming for large strings |

| Shadow/Reflection | Faint or flickering LEDs | Needs total darkness; not useful for completely dead circuits |

| Tap Test | Intermittent connections | May give false positives; temporary results |

| Visual Inspection | Obvious damage or looseness | Misses internal failures |

Real-World Example: Fixing a Patio Light String

Sarah had a 100-bulb warm-white LED string running along her deck railing. After winter storage, the last 25 bulbs wouldn’t light. She didn’t own a multimeter and wasn’t comfortable cutting wires.

She began by plugging in the string at night. In the dark, she noticed the 76th bulb emitted a faint orange flicker—unlike the steady white of the others. Using a spare bulb from a broken set, she replaced it. The entire remaining section lit up immediately.

Curious, she examined the removed bulb under a magnifier. One of the tiny internal wires inside the LED casing appeared disconnected. Though the lens was intact, the semiconductor chip had lost connection to the lead. No amount of tapping or reseating would have fixed it—replacement was the only solution.

This case illustrates how combining darkness testing with the swap method can efficiently pinpoint issues—even without tools.

Preventive Measures and Maintenance Tips

While troubleshooting is useful, preventing failures saves time and extends the life of your LED strings.

- Store properly: Coil loosely and avoid tight bends near connectors.

- Use timers: Limit daily runtime to reduce thermal cycling stress.

- Keep dry: Moisture accelerates corrosion in sockets and PCBs.

- Cover connections: Use waterproof caps or silicone tape on plug ends.

- Handle gently: Never pull the string by the wires when installing.

FAQ

Can a single dead LED bulb really turn off a whole section?

Yes. In series-wired segments, current must flow through each LED in sequence. If one fails open-circuit (the most common failure), the path breaks and no current flows—so the entire segment goes dark.

Is it safe to test LED bulbs by touching them while the string is on?

Generally yes, because most decorative LED strings operate at low voltage (especially battery-powered or USB types). However, mains-powered strings (120V) can deliver dangerous shocks if insulation is damaged. Always unplug before handling bulbs or making adjustments.

Why do some LED strings have shunts, and do they help?

Unlike incandescent bulbs, most LEDs do not use shunts. Shunts are bypass wires that activate when a filament breaks, keeping the circuit closed. LEDs lack this feature, which is why one failure can disable a whole segment.

Step-by-Step Summary

Follow this timeline to effectively test individual LED bulbs without tools:

- Unplug the string and perform a full visual inspection.

- Plug in and observe in complete darkness to detect faint glows or flickers.

- Mark suspect bulbs using tape or notes.

- Use the tap test to check for intermittent connections.

- Swap each suspect bulb with a known-working one from a live section.

- Re-test after each swap to confirm if the issue resolves.

- If no bulbs respond, inspect wiring between segments for damage.

- Replace faulty bulbs or consider retiring the string if multiple failures occur.

Final Thoughts

Testing individual LED bulbs without a multimeter is entirely possible with patience, observation, and a few clever tricks. While professional tools offer precision, everyday methods like swapping, tapping, and dark-room inspection can solve most common problems. Understanding how LED strings are wired, recognizing subtle signs of failure, and practicing preventive care will keep your lights glowing season after season.

You don’t need advanced electronics knowledge to maintain your decorative lighting. With these accessible techniques, anyone can extend the life of their LED strings, reduce waste, and enjoy reliable performance—no special equipment required.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?