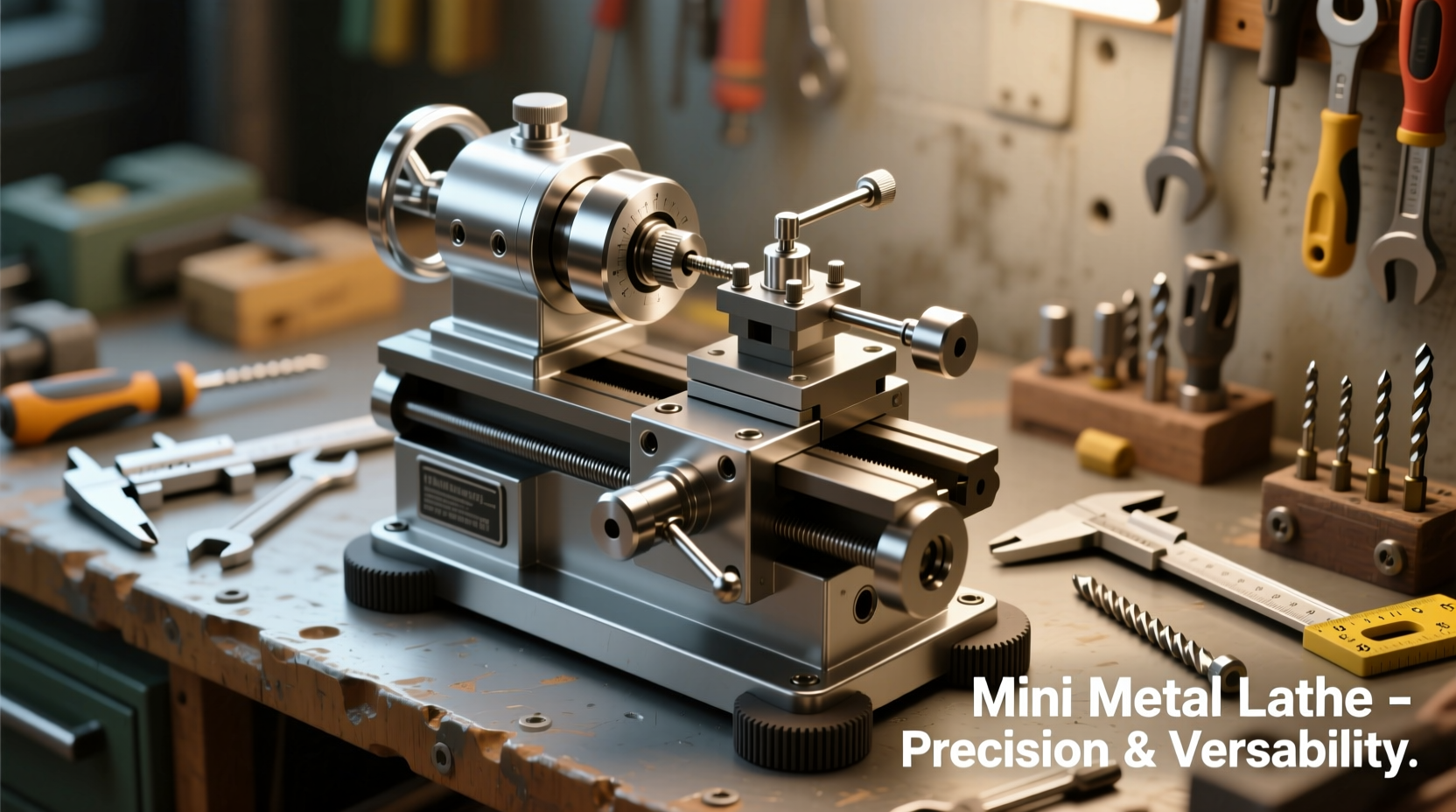

For hobbyists, machinists, and makers who value accuracy and versatility in a compact workspace, a mini metal lathe is an indispensable tool. These machines bring industrial-level capabilities into home workshops, enabling users to turn, drill, thread, and shape metal with high precision. Whether you're crafting custom parts, restoring vintage components, or prototyping mechanical designs, selecting the right mini lathe can dramatically expand your project possibilities. Unlike full-sized lathes, mini models offer space efficiency without sacrificing core functionality—provided you choose wisely.

Understanding Mini Metal Lathes: What Sets Them Apart

A mini metal lathe typically refers to a benchtop machine with a swing over bed under 12 inches and a distance between centers ranging from 6 to 14 inches. Despite their size, many models deliver remarkable rigidity and accuracy, especially those built with cast iron bases and precision-ground leadscrews. The primary advantage lies in accessibility: they are easier to set up, require less floor space, and often come at a fraction of the cost of larger industrial units.

Mini lathes excel in tasks such as:

- Turning small shafts and pins

- Cutting precise external and internal threads

- Machining brass, aluminum, and mild steel components

- Producing custom fittings, bushings, and spacers

- Supporting model engineering and clockmaking

However, limitations exist. Most mini lathes lack the power and mass to handle aggressive cuts in tough materials like stainless steel or titanium. They also tend to have simpler gear trains and fewer automation features than professional-grade machines. Still, for precision-focused DIY applications, these trade-offs are often acceptable.

Top Mini Metal Lathe Models for Precision and Reliability

Choosing the best mini lathe depends on your intended use, material preferences, and budget. Below is a comparison of five widely respected models known for performance and build quality in real-world settings.

| Model | Swing Over Bed | Distance Between Centers | Motor Power (HP) | Key Features |

|---|---|---|---|---|

| Prominent Tools PM-1220X | 12\" | 20\" | 0.95 | Digital readout (DRO), variable speed, heavy-duty base |

| Grizzly G0602 | 7\" | 13\" | 0.5 | Geared head, backgear for low-speed torque, compound rest |

| JET JMD-18 | 8\" | 18\" | 0.75 | Quick-change gearbox, metric/imperial threading, DRO-ready |

| Central Machinery 7x12 (Harbor Freight) | 7\" | 12\" | 0.5 | Budget-friendly, basic threading, ideal for beginners |

| Smithy Granite 1324XL | 13\" | 24\" | 1.0 | All-in-one combo unit (lathe + mill), CNC-ready, robust construction |

The Smithy Granite stands out as a premium option due to its dual-function design and granite composite base, which reduces vibration. Meanwhile, the Grizzly G0602 is favored by purists for its geared-head transmission and ease of modification. For those on a tight budget, the Central Machinery 7x12 offers surprising capability at under $500, though it may require tuning out of the box.

“Even a modest mini lathe, when properly trammed and maintained, can achieve tolerances within ±0.001” — sufficient for most mechanical repairs and custom fabrication.” — David Lin, Mechanical Fabrication Instructor, Portland Makers Guild

Essential Features for Precision Work

Not all mini lathes are created equal when it comes to fine machining. To ensure consistent accuracy, prioritize these key features:

- Digital Readout (DRO): Eliminates reliance on vernier scales; provides real-time position feedback on cross-slide and carriage.

- Compound Slide with Micrometer Dial: Enables precise angular cuts and taper turning down to 0.001” increments.

- Leadscrew with Half-Nut Mechanism: Essential for cutting accurate screw threads without manual handwheel coordination.

- Variable Speed Control: Allows optimization of spindle RPM based on material and diameter—critical for surface finish and tool life.

- Rigid Tailstock with Morse Taper: Ensures alignment stability during long turning operations and supports center-drilling.

Additionally, consider retrofit potential. Many advanced users upgrade their mini lathes with aftermarket DRO systems, servo drives, or even CNC kits. Machines with accessible electronics and standard mounting patterns offer greater long-term flexibility.

Step-by-Step Guide to Setting Up Your Mini Lathe for First Use

New lathes, especially budget models, often arrive with excess lubricant, misaligned components, or loose fasteners. Follow this sequence before beginning any precision work:

- Unpack and clean: Remove shipping grease using mineral spirits and a lint-free cloth. Pay attention to ways, gears, and lead screws.

- Level and bolt down: Place on a sturdy bench and use a precision level to ensure flatness front-to-back and side-to-side.

- Check alignment: Perform a “test cut” across a soft metal rod (e.g., aluminum) to detect taper—indicative of headstock misalignment.

- Adjust belt tension: Ensure drive belts are snug but not overly tight to prevent premature motor wear.

- Lubricate moving parts: Apply light machine oil to ways, gears, and feed rods per manufacturer instructions.

- Test threading function: Cut a short thread on scrap material and verify pitch with a thread gauge.

Real-World Application: Restoring a Vintage Bicycle Component

Consider the case of Mark R., a bicycle restoration enthusiast in Boulder, CO. He needed to refurbish a rare 1940s French crank arm that had a worn pedal thread. Off-the-shelf taps wouldn’t fit, and replacement parts were unavailable. Using his Grizzly G0602 mini lathe, he:

- Mounted the crank in a three-jaw chuck using soft jaws to avoid marring

- Center-drilled the damaged hole and reamed it to a consistent diameter

- Used a custom ground HSS tool bit to cut a 14mm x 1.25mm metric thread

- Polished the finished thread with a chamfer tool for smooth engagement

The entire process took under two hours. The restored crank now functions flawlessly and retains its original character. This example illustrates how a capable mini lathe bridges the gap between preservation and practicality in niche repair work.

DIY Project Ideas Enabled by a Mini Lathe

Once operational, a mini lathe opens doors to creative and functional builds. Some popular project types include:

- Custom pen blanks turned from brass or acrylic

- Replacement knobs and dials for antique radios or amplifiers

- Small pulleys and flywheels for model steam engines

- Thread adapters (e.g., M6 to 1/4\"-20) for photography or robotics gear

- Handmade bolts, studs, and spindles for furniture or art installations

These projects not only develop machining skills but also yield unique, high-quality components impossible to source commercially.

Frequently Asked Questions

Can a mini lathe cut stainless steel?

Yes, but cautiously. Small-diameter stainless rods (under 1/2\") can be machined using sharp carbide tooling, slow speeds, and consistent feed rates. Larger or hardened grades may exceed the machine’s rigidity and should be avoided.

How accurate are mini lathes out of the box?

Most entry-level models achieve ±0.002” repeatability after basic setup. Higher-end or tuned versions can reach ±0.0005” with DRO and thermal stabilization. Accuracy heavily depends on proper maintenance and operator technique.

Do I need a separate threading tool for each pitch?

No. A single high-quality HSS tool bit can cut multiple thread pitches if ground to the correct included angle (typically 60° for metric/UN threads). The lathe’s gear train handles pitch variation via change gears or quick-change gearbox settings.

Final Checklist Before Purchase

- Verify swing and distance between centers match your typical workpiece sizes

- Confirm availability of spare parts and technical support

- Check if digital readout or CNC conversion is supported

- Read user reviews focusing on long-term durability and vibration levels

- Ensure the seller offers a warranty and return policy

Conclusion

A well-chosen mini metal lathe empowers precision craftsmanship in even the smallest workshop. From delicate instrument repairs to inventive DIY builds, these machines combine affordability, capability, and scalability in one compact form. By understanding your needs, prioritizing key features, and investing time in proper setup, you unlock a new dimension of making—one where exact dimensions, flawless finishes, and custom solutions become routine.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?