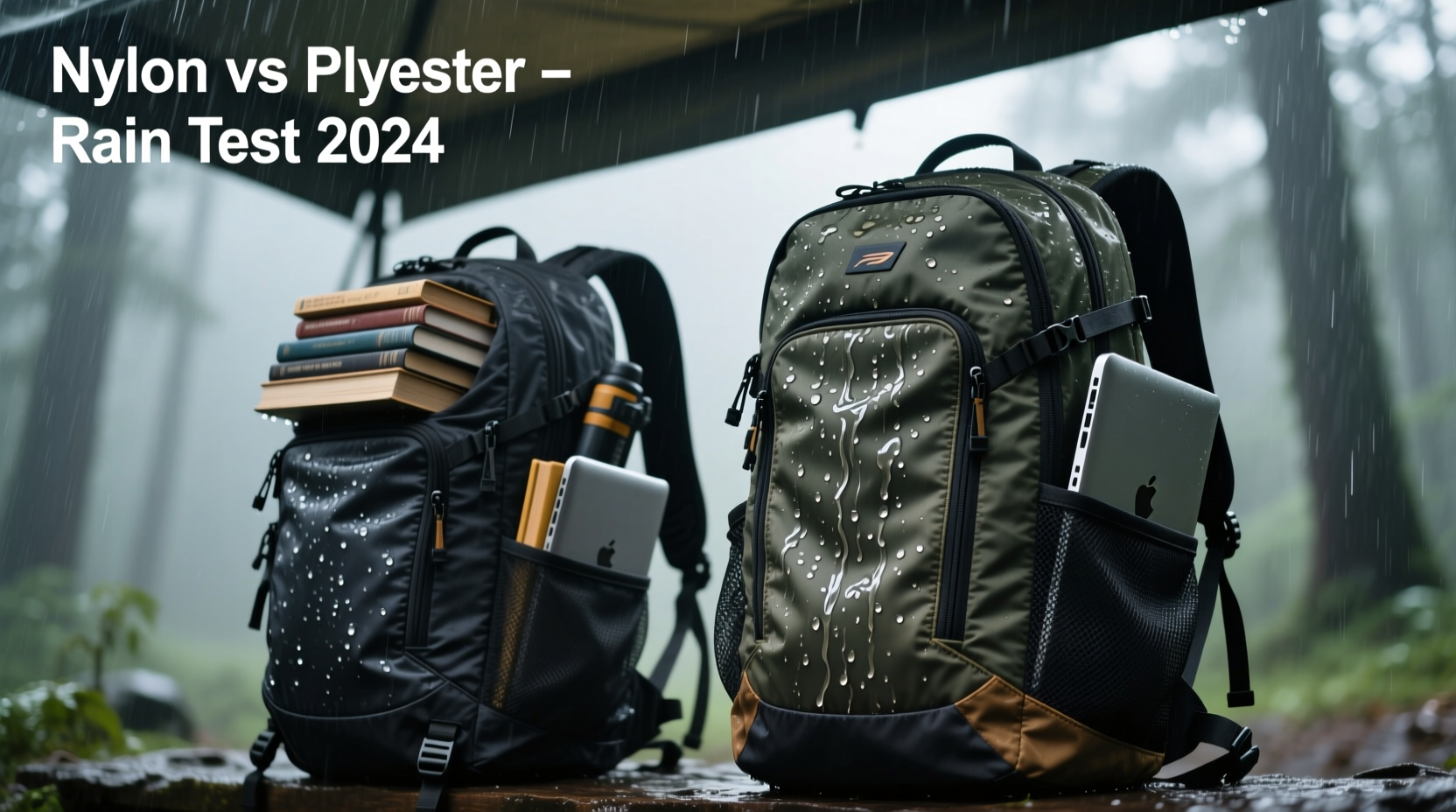

When choosing a backpack for outdoor use—especially in unpredictable weather—the fabric matters more than most people realize. Nylon and polyester are the two most common materials used in modern backpack construction, both praised for their lightweight nature and resilience. But when faced with torrential downpours, muddy trails, or extended exposure to moisture, one clearly outperforms the other. Understanding the differences between nylon and polyester isn’t just about marketing jargon—it’s about staying dry, protecting your gear, and ensuring your backpack lasts through seasons of hard use.

This guide breaks down the structural, chemical, and practical distinctions between nylon and polyester in wet conditions. We’ll explore how each fabric reacts to water, how long they last under stress, and what real-world users can expect during hikes, commutes, or travel in rainy climates.

Material Science: How Nylon and Polyester Respond to Water

Nylon and polyester are both synthetic polymers derived from petroleum, but their molecular structures differ significantly, leading to different behaviors when exposed to moisture.

Nylon is hygroscopic, meaning it absorbs small amounts of water into its fibers. While this gives it greater flexibility and toughness in some applications, it also means that prolonged exposure to rain can cause it to swell slightly and take longer to dry. However, high-denier nylon (such as 600D or 1000D) is often coated with polyurethane (PU) or silicone, dramatically improving its water resistance.

Polyester, on the other hand, is inherently hydrophobic. It does not absorb water, making it naturally more resistant to dampness. This characteristic allows polyester to maintain its shape and strength even after hours of rain exposure. Additionally, because it doesn’t retain moisture, it resists mildew and odor buildup better than untreated nylon.

While both fabrics are typically treated with durable water repellent (DWR) coatings, polyester tends to hold onto these treatments longer due to its stable surface chemistry. Nylon’s ability to absorb moisture can degrade DWR over time unless properly maintained.

Water Resistance Comparison: Real-World Performance

In controlled lab tests, polyester consistently shows lower water absorption rates. For example, untreated polyester absorbs less than 0.4% of its weight in water, while nylon can absorb up to 2–4% depending on thickness and weave. That may sound minor, but in heavy rain over several hours, that added weight and saturation can make a noticeable difference.

Backpacks made from ripstop polyester—common in ultralight hiking models—often feature taped seams and roll-top closures, creating a near-waterproof barrier. Brands like Osprey, Deuter, and Patagonia use high-density polyester in their rain-tested models precisely because of its predictable behavior under wet conditions.

Nylon backpacks, particularly those made from Cordura® or ballistic nylon, offer superior abrasion resistance, which is valuable in rugged terrain. However, without proper waterproofing, nylon’s slight absorbency can allow moisture to seep through over time, especially at stress points like zippers and seams.

One critical factor often overlooked is seam construction. Even the most water-resistant fabric fails if seams aren’t sealed. Most premium backpacks now include heat-sealed or taped seams, but budget models may skip this step, leaving vulnerabilities regardless of fabric type.

“Polyester’s natural resistance to water makes it ideal for all-weather gear. When combined with proper construction, it outperforms nylon in sustained rain events.” — Dr. Lena Torres, Materials Scientist at Outdoor Gear Lab

Comparative Analysis: Nylon vs Polyester in Key Categories

| Feature | Nylon | Polyester |

|---|---|---|

| Water Absorption | 2–4% (can wick moisture) | <0.4% (highly resistant) |

| Drying Time | Slower (absorbs moisture) | Faster (repels water) |

| Tensile Strength | Higher (more durable under strain) | Slightly lower but still strong |

| UV Resistance | Moderate (degrades faster in sunlight) | Excellent (resists sun damage) |

| Mildew Resistance | Lower (if damp for long periods) | High (doesn’t retain moisture) |

| DWR Coating Longevity | Shorter (needs reapplication) | Longer-lasting |

| Weight | Slightly heavier at same denier | Lighter, especially in ripstop forms |

The table highlights a trade-off: nylon wins in raw strength and tear resistance, but polyester excels in environmental stability, particularly against water and UV exposure. For backpacks used primarily in rainy or humid climates, polyester’s advantages often outweigh nylon’s toughness.

Case Study: Backpack Performance During a Pacific Northwest Hiking Trip

Consider a real-world scenario involving two hikers tackling a three-day trek through Washington’s Olympic Peninsula—a region known for persistent drizzle and sudden downpours.

Hiker A carried a 50L backpack made from 600D nylon with PU coating. Hiker B used a similar-sized pack constructed from 500D ripstop polyester with welded seams and a DWR finish.

On day one, both packs performed well. Light rain beaded off the surfaces thanks to factory-applied DWR. By day two, however, continuous mist began affecting the nylon pack. The shoulder straps felt slightly damp, and the back panel showed signs of moisture transfer. The polyester pack remained dry to the touch, with water actively rolling off the fabric.

On day three, after crossing a stream and enduring a two-hour thunderstorm, Hiker A reported damp clothing inside the pack despite using a liner. Hiker B’s electronics and sleeping bag stayed completely dry. Post-trip inspection revealed the nylon pack took nearly two full days to dry indoors, while the polyester model was ready for storage within 12 hours.

This case illustrates that while both materials can handle light rain, polyester’s inherent water resistance provides a tangible advantage in prolonged wet conditions.

Maintenance and Longevity: How Care Impacts Performance

No matter the material, how you care for your backpack directly affects its lifespan and water resistance. Both nylon and polyester benefit from regular cleaning, but improper maintenance can degrade protective coatings.

Nylon requires more attention. Because it absorbs moisture, storing it while damp can lead to mold growth and fiber degradation. Users should always air-dry nylon packs thoroughly before storage. Additionally, frequent washing without reapplying DWR can strip the fabric’s ability to repel water.

Polyester is more forgiving. Its resistance to moisture and UV rays means it can endure repeated wet-dry cycles with minimal wear. However, dirt and grime can clog the fabric’s pores, reducing breathability and water beading. A simple rinse with mild soap and lukewarm water every few months preserves performance.

Step-by-Step Guide to Maintaining Water Resistance

- After Each Wet Use: Wipe down the exterior with a clean cloth and unzip all compartments to promote airflow.

- Air-Dry Completely: Hang the backpack upside-down in a well-ventilated area, away from direct heat or sunlight.

- Inspect for Wear: Check seams, zippers, and high-stress areas for fraying or coating loss.

- Clean Gently: Use a soft brush and non-detergent cleaner to remove mud or stains.

- Reapply DWR: Once every 3–6 months, spray an even coat of DWR treatment and let it cure per manufacturer instructions.

- Store Properly: Keep in a cool, dry closet—never compressed or in plastic.

Choosing the Right Backpack: A Practical Checklist

When selecting a backpack for rainy environments, don’t rely solely on fabric type. Use this checklist to ensure maximum protection:

- ✅ Fabric is at least 400D polyester or 600D nylon with waterproof coating

- ✅ Seams are taped or sealed (not just stitched)

- ✅ Zippers are covered or water-resistant (YKK AquaGuard® preferred)

- ✅ Includes a built-in rain cover or roll-top closure

- ✅ Has external attachment points for gear that need quick access

- ✅ Lining is waterproof (e.g., TPU or PU-coated interior)

- ✅ Manufacturer specifies weather resistance (look for IPX ratings or field testing data)

Brands like Arc'teryx, Cotopaxi, and Hyperlite Mountain Gear prioritize polyester in their ultralight, weather-ready designs. Meanwhile, traditional hiking brands such as Gregory and The North Face often use reinforced nylon in heavier-duty models where abrasion resistance is key.

Frequently Asked Questions

Is nylon completely waterproof?

No. While many nylon backpacks are treated to be water-resistant, untreated nylon absorbs moisture. Even coated nylon can leak at seams or under pressure. True waterproofing requires sealed construction and additional layers like TPU laminates.

Can I make my polyester backpack more water-resistant?

Yes. Although polyester is naturally hydrophobic, applying a DWR spray enhances beading and shortens drying time. Reapplication every few months maintains peak performance, especially after cleaning.

Which lasts longer in rainy climates—nylon or polyester?

Polyester generally lasts longer in consistently wet environments due to its resistance to moisture, UV degradation, and mildew. Nylon can perform well but requires more diligent maintenance to prevent long-term damage from damp storage or repeated soaking.

Final Verdict: Which Holds Up Better in Heavy Rain?

For sheer performance in heavy rain, **polyester is the superior choice**. Its natural resistance to water absorption, faster drying time, and longer-lasting protective finishes make it ideal for travelers, hikers, and commuters in wet climates. While nylon offers unmatched strength and abrasion resistance—valuable in rocky or forested terrain—its tendency to absorb moisture undermines its reliability during extended rainfall.

That said, the best backpacks often combine materials strategically. Some models use polyester for the main body and nylon for high-wear areas like base panels or hip belts. Others integrate hybrid laminates (like polyester with TPU coating) to achieve both lightness and full waterproofing.

The takeaway is clear: if your primary concern is staying dry in relentless rain, prioritize polyester-based packs with sealed seams and quality craftsmanship. Pair that with consistent care, and you’ll have a reliable companion for years—even in the wettest conditions.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?