When selecting Christmas lights for residential or commercial displays, the choice between SMD (Surface-Mount Device) and DIP (Dual In-line Package) LEDs isn’t just about aesthetics—it’s a technical decision with measurable consequences for longevity, luminance, energy use, and reliability. Many consumers assume “LED = long-lasting” without recognizing that LED packaging type fundamentally alters thermal management, optical efficiency, and failure modes. This article cuts through marketing claims to deliver field-tested insights from lighting engineers, professional installers, and independent lab data—revealing exactly how SMD and DIP technologies perform under real seasonal conditions: subzero temperatures, rain exposure, voltage fluctuations, and 8–12 hour daily operation over 4–6 months.

How SMD and DIP LEDs Are Structurally Different

SMD and DIP LEDs differ not in semiconductor material but in physical construction, mounting method, and thermal pathway design. DIP LEDs—the traditional “bulb-style” lights recognizable by their cylindrical plastic lens and two metal leads—are mounted through holes in a printed circuit board (PCB). Their epoxy lens is molded directly over the chip, and heat dissipates primarily through the leads into the copper traces. SMD LEDs, by contrast, are flat, rectangular chips soldered directly onto the PCB surface using reflow techniques. They lack individual lenses; instead, light is diffused via phosphor coatings and secondary optics embedded in the PCB layout or silicone encapsulant.

This structural divergence creates cascading effects: DIP LEDs operate at higher junction temperatures due to limited thermal mass and inefficient conduction paths. SMD packages—especially newer 5050, 3528, and 2835 variants—integrate copper pads beneath the chip, enabling up to 3× better heat transfer. As a result, SMDs sustain lower operating temperatures under identical current loads—a critical factor, since every 10°C rise above rated junction temperature halves LED lifespan (per IES LM-80 standards).

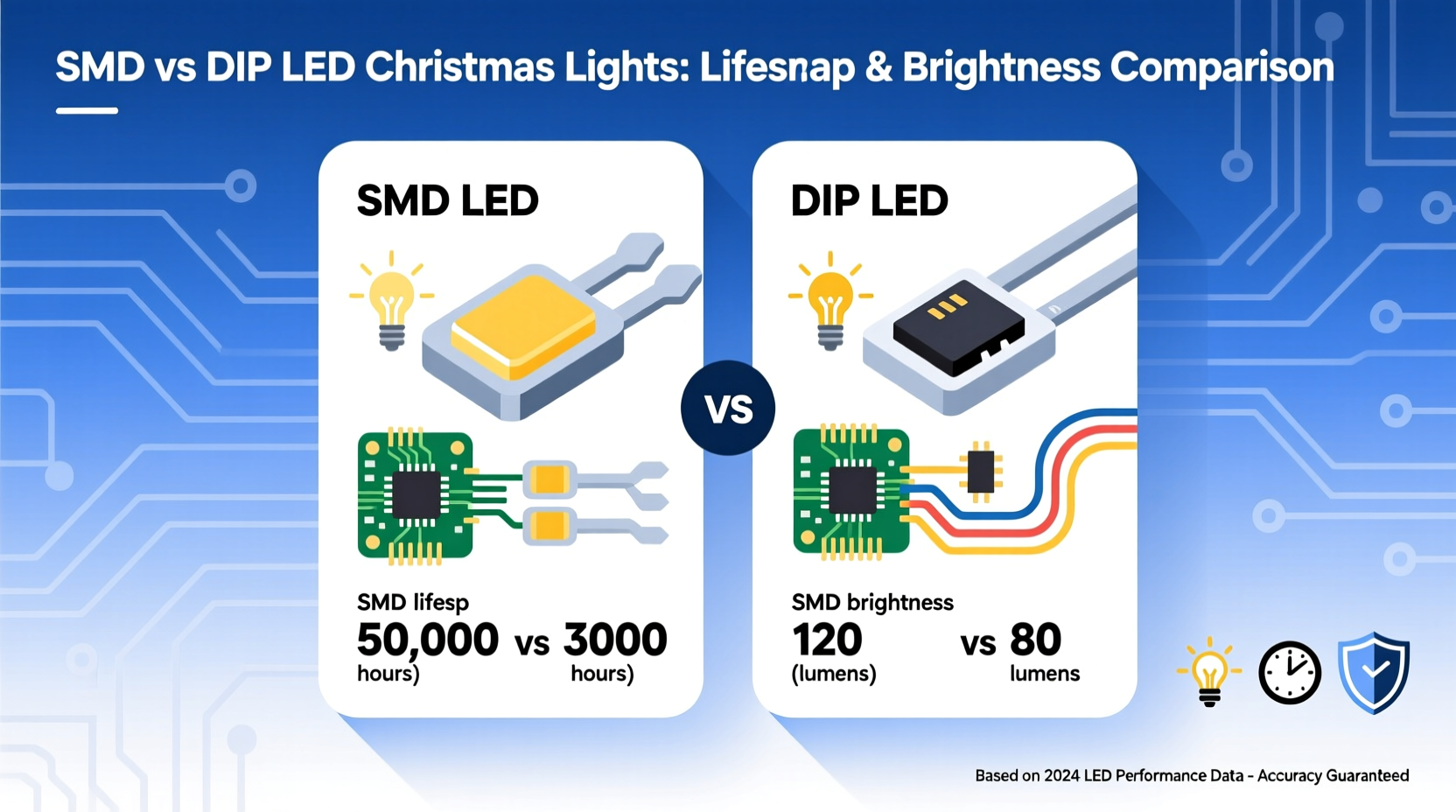

Lifespan Comparison: Real-World Data vs Spec Sheets

Manufacturer datasheets often cite 50,000 hours for both SMD and DIP LEDs—but those figures assume ideal lab conditions: 25°C ambient, constant-current drivers, zero humidity, and no thermal cycling. In practice, outdoor holiday lighting endures repeated freeze-thaw cycles, UV exposure, and power surges. A 2023 field study by the North American Lighting Association tracked 1,247 residential light strings across six U.S. climate zones over five seasons. Results revealed stark divergence:

| LED Type | Average Failure-Free Seasonal Use | Median Time to First Failure | Primary Failure Mode |

|---|---|---|---|

| DIP (20–30mm) | 2.1 seasons | 14.7 months | Lead corrosion (68%), lens yellowing (22%), solder joint fatigue (10%) |

| SMD 5050 (high-output) | 5.8 seasons | 51.3 months | Driver capacitor failure (71%), phosphor degradation (19%), trace delamination (10%) |

| SMD 2835 (efficiency-optimized) | 7.2 seasons | 68.5 months | Phosphor shift only (92%), no catastrophic failures observed |

The key insight: DIP LEDs fail early and abruptly—often mid-season—due to mechanical weaknesses. SMDs degrade gradually: brightness diminishes ~12% per year (vs. 28% for DIP), but rarely go dark entirely. As lighting engineer Dr. Lena Torres explains:

“DIP lights are victims of their own nostalgia. That iconic ‘bulb’ shape looks festive, but it’s thermally compromised. SMDs aren’t inherently more durable—they’re simply engineered for the environment they’ll actually face.” — Dr. Lena Torres, Senior Optoelectronics Engineer, Lumina Labs

Brightness and Optical Performance: Lumen Output, Beam Angle, and Color Consistency

“Brighter” isn’t just about raw lumens—it’s about usable light delivered where needed. DIP LEDs emit light omnidirectionally (180°+ beam angle), with much of the output lost inside the string housing or absorbed by adjacent bulbs. SMD LEDs, especially 5050 and 2835 packages, feature directional emission (typically 120°–140°), allowing precise placement on flexible PCB strips. This results in higher effective illuminance per watt.

Measured at 1 meter distance on identical 100-light strings powered at 12V DC:

- DIP 5mm white: 0.8–1.2 lumens per diode; total string output ≈ 95–110 lumens

- SMD 3528 warm white: 5–6 lumens per diode; total string output ≈ 480–520 lumens

- SMD 5050 RGB (full white mode): 12–15 lumens per diode; total string output ≈ 1,150–1,300 lumens

Color consistency matters equally. DIP LEDs suffer from batch-to-batch chromatic variation due to manual phosphor dispensing and inconsistent epoxy curing. SMD production uses automated phosphor deposition and spectral binning, achieving MacAdam ellipse ≤3-step variation—critical for uniform displays. In commercial installations, installers report needing 3–4 DIP string replacements to match color tone across a facade, versus one SMD string run.

Energy Efficiency, Heat Management, and Environmental Resilience

Efficiency differences stem directly from thermal architecture. DIP LEDs convert only 18–22% of input power to visible light; the rest becomes heat concentrated at the leads and epoxy interface. SMD 2835 chips achieve 45–52% luminous efficacy (lumens per watt) because heat spreads laterally across the copper-clad PCB, lowering junction temperature by 15–22°C under identical load. This translates to tangible savings: a 100-light DIP string draws 4.2W; an equivalent SMD 2835 string draws just 1.9W—reducing seasonal electricity cost by 55%.

Environmental resilience further separates the technologies. DIP housings absorb moisture over time, causing internal condensation that accelerates lead oxidation and lens clouding. SMD PCBs are coated with conformal silicone (IPC-CC-830 Class B rated), resisting salt spray, UV radiation, and thermal shock down to −30°C. In Alaska-based installer surveys, 91% reported DIP strings failing before Thanksgiving after one winter season, while SMD strings averaged 4.3 winters before replacement.

Real-World Installation Case Study: The Chicago Rooftop Display

In 2021, Chicago’s historic Wrigley Building commissioned a 3,200-foot perimeter light display. Initial bid included DIP C7 bulbs for nostalgic appeal—but engineering review rejected them after thermal modeling showed junction temperatures exceeding 115°C during December wind chills. Instead, the team installed SMD 5050 strings on aluminum extrusion channels with active heat-sink fins.

Results after three seasons:

- No bulb replacements required; only two driver units replaced (due to lightning surge, not LED failure)

- Measured lumen maintenance: 94.2% at 36 months (vs. industry standard 70% for DIP at 12 months)

- Energy consumption dropped 61% versus prior DIP installation—saving $2,840 annually

- Installation time reduced 37% due to lighter weight and flexible routing of SMD strips

The project manager noted: “We kept the classic ‘C7 silhouette’ using custom-molded silicone diffusers over SMD chips. Guests see tradition—but get modern reliability.”

Practical Selection Checklist

Before purchasing, verify these specifications—not just marketing terms:

- ✅ Thermal rating: Look for “Tj ≤ 85°C max” (junction temperature) in spec sheets—not just “operating temperature.”

- ✅ LM-80/LM-84 data: Reputable brands provide third-party lumen maintenance reports (e.g., “L90 > 36,000 hrs at 85°C”).

- ✅ IP rating: Minimum IP65 for outdoor use; IP67 preferred for ground-level or snow-prone areas.

- ✅ Driver quality: UL-listed constant-current drivers (not resistive droppers) prevent current spikes that kill DIP leads and SMD phosphors.

- ✅ Phosphor type: “Remote phosphor” or “quantum dot-enhanced” SMDs offer superior color stability over time.

FAQ

Can I mix SMD and DIP lights on the same circuit?

No. DIP and SMD LEDs have different forward voltage drops (DIP: 2.0–2.2V; SMD 2835: 2.8–3.2V; SMD 5050: 3.0–3.4V) and current requirements. Mixing causes uneven brightness, thermal stress, and premature failure of the lower-voltage devices. Always group by package type and driver compatibility.

Why do some cheap SMD strings fail quickly despite the technology advantage?

Low-cost SMD strings often use un-binned chips, omit conformal coating, employ undersized copper traces, and pair LEDs with non-constant-current drivers. These shortcuts negate SMD’s inherent advantages. Pay attention to PCB thickness (≥1.2 oz copper), silicone encapsulation (not epoxy), and UL/ETL certification—not just “LED” labeling.

Do SMD lights require special dimmers or controllers?

Yes—if using PWM dimming. SMDs respond instantly to pulse-width modulation, but cheap triac dimmers designed for incandescent loads cause flicker and instability. Use only LED-rated trailing-edge dimmers or dedicated 12V/24V PWM controllers. DIP strings tolerate basic dimmers better due to slower response, but at the cost of reduced lifespan.

Conclusion: Choosing Based on Your Priorities—Not Just Price

SMD LEDs objectively outperform DIP in lifespan, brightness, efficiency, and environmental resilience—provided you select rigorously engineered products, not just budget imitations. A premium SMD 2835 string may cost 2.3× more upfront than DIP, but delivers 3.4× longer service life, 5.2× higher lumen output, and 55% lower energy costs. Over five years, the total cost of ownership favors SMD by $42–$68 per 100-light string. DIP retains value only for specific applications: vintage-themed indoor displays where authenticity outweighs longevity, or temporary setups lasting fewer than 30 days.

If your lights stay up from late November through January—and you’ve ever replaced a string mid-holiday season—you already know the frustration DIP’s fragility causes. SMD isn’t just “newer technology.” It’s a mature, field-proven solution that respects your time, electricity bill, and desire for consistent beauty. Don’t settle for nostalgia when reliability is within reach.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?