Reclaimed wood from discarded pallets is a goldmine for DIYers, offering sturdy, affordable, and sustainable material for furniture, shelving, garden beds, and more. However, extracting usable planks without damaging them—or injuring yourself—requires the right approach. Many beginners rush in with hammers and crowbars, only to end up with splintered boards or bent nails. Done correctly, pallet disassembly can yield clean, reusable lumber while minimizing waste and risk.

This guide walks through every step of the process: from identifying safe pallets to removing fasteners efficiently and repurposing the wood effectively. Whether you're building a coffee table or a backyard planter, mastering this skill opens up a world of creative possibilities.

How to Identify Safe Pallets for Disassembly

Not all pallets are created equal. Some carry hazardous chemicals, others are structurally unsound, and many have been exposed to contaminants. Before you even think about grabbing tools, inspect the pallet carefully.

Look for the International Plant Protection Convention (IPPC) stamp, typically located on one of the stringers. This marking reveals how the pallet was treated:

| Code | Treatment | Safety for DIY Use |

|---|---|---|

| HT | Heat-treated | ✅ Safe – ideal for indoor projects |

| MB | Methyl bromide fumigation | ❌ Avoid – toxic chemical residue |

| DB | Debarked | ✅ Generally safe if combined with HT |

| No Stamp | Unknown origin | ⚠️ Use with caution; assume it's unsafe |

Pallets marked “HT” have been heated to kill pests and pathogens and pose no chemical risk. Those stamped “MB” were treated with methyl bromide, a pesticide banned in many countries due to its toxicity. Never use MB-treated wood for furniture, food-related items, or children’s toys.

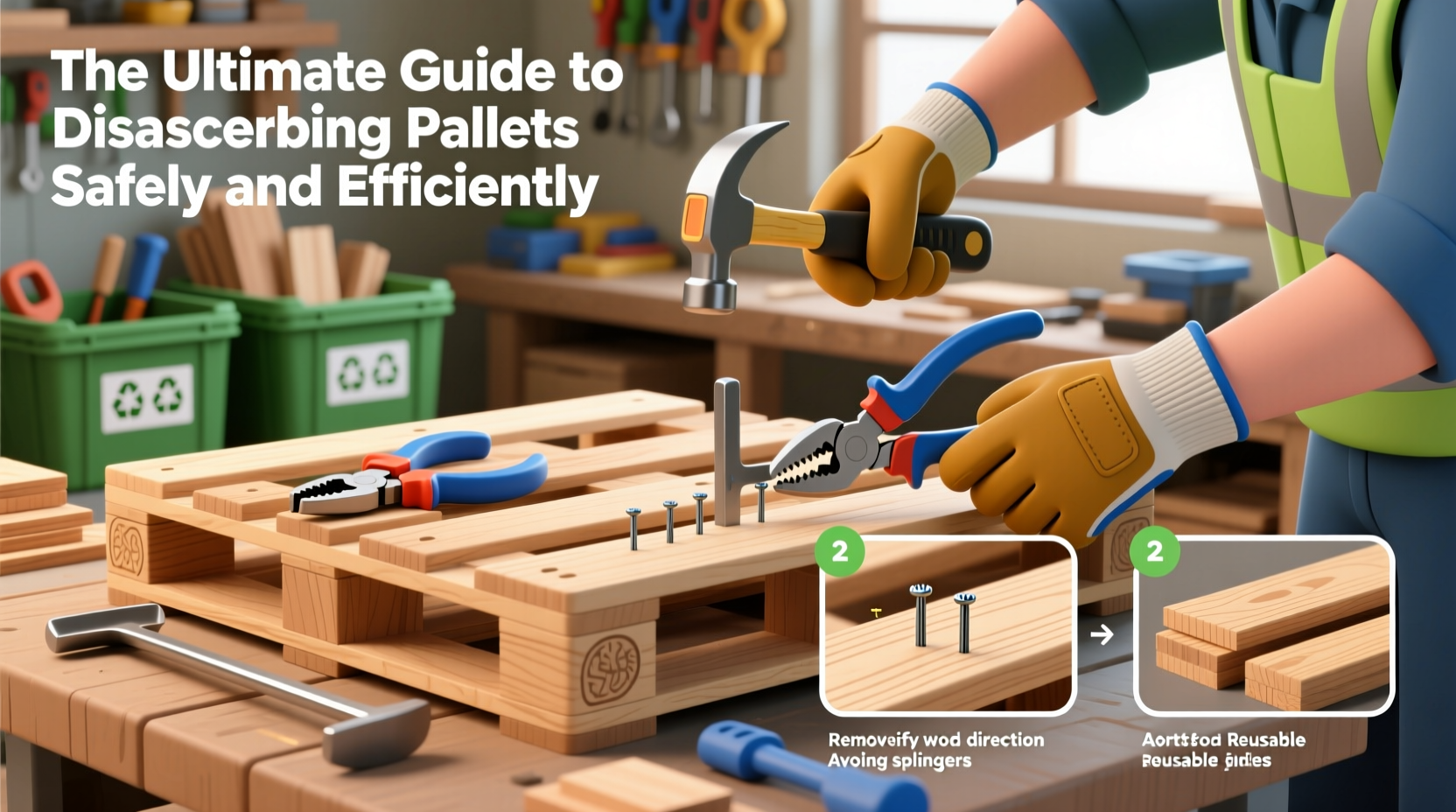

Essential Tools for Efficient Pallet Breakdown

The right tools make disassembly faster, safer, and less destructive. Using brute force with a claw hammer often results in broken planks and fatigue. Invest in a few key tools to streamline the process.

- Wrecking bar (or pry bar): A 15–24 inch model provides excellent leverage for separating boards.

- Framing hammer: Heavier than a standard claw hammer, better for driving wedges and loosening joints.

- Cat’s paw or nail puller: Precisely removes nails that remain after prying.

- Circular saw or reciprocating saw: For cutting through stubborn nails or damaged sections.

- Safety gear: Gloves, safety goggles, and steel-toe boots protect against sharp edges and flying debris.

“Efficiency starts before the first nail is pulled. Organize your workspace and tools so each motion flows into the next.” — Marcus Reed, Carpenter & Urban Woodworker

Step-by-Step Guide to Disassembling a Pallet Safely

Follow this methodical sequence to maximize wood recovery and personal safety.

- Inspect and stabilize: Place the pallet on a flat, stable surface. Remove any loose debris or protruding nails.

- Start at one end: Choose a corner where deck boards meet the stringer. Insert the wrecking bar between the board and stringer.

- Lever gently: Apply steady upward pressure to pop the board free. Avoid sudden jerks that can snap the wood.

- Remove nails: Once lifted, use a cat’s paw or hammer claw to extract nails still embedded in the plank.

- Work systematically: Move board by board along the stringer. Flip the pallet when necessary to access both sides.

- Break down stringers (optional): If needed, dismantle stringers using a saw or repeated prying, depending on their construction.

- Sort and store: Group planks by size and condition. Set aside cracked or heavily nailed pieces for outdoor use or kindling.

Avoid These Common Pallet Disassembly Mistakes

Even experienced DIYers fall into traps that reduce efficiency or compromise safety. Recognizing these pitfalls helps you work smarter.

- Skipping safety gear: Flying nails and splinters are real hazards. Always wear eye protection and gloves.

- Using excessive force: Smashing with a hammer can shatter wood. Controlled leverage preserves integrity.

- Ignoring rust and contamination: Clean metal surfaces with a wire brush before handling. Wash hands after working with unknown pallets.

- Disassembling on concrete: Hard surfaces dull tools and bounce nails unpredictably. Work on dirt, grass, or rubber mats when possible.

- Leaving nails in reclaimed wood: Hidden fasteners can ruin saw blades or injure users later. Inspect every plank thoroughly.

Real-World Example: Building a Bench from Reclaimed Pallet Wood

When Sarah Thompson decided to build a rustic outdoor bench for her patio, she visited a local garden center and collected three HT-stamped pallets at no cost. Over a weekend, she disassembled them using a 20-inch wrecking bar and framing hammer, recovering 18 usable planks. She sanded the wood, removed every nail, and arranged the boards into a slatted seat supported by two salvaged cinder blocks.

By avoiding MB-treated pallets and taking time to extract nails properly, Sarah completed the project for under $10 (mostly sandpaper and exterior sealant). Her bench has lasted four years with minimal maintenance—proof that careful disassembly pays long-term dividends.

What to Do With the Recovered Wood

Once cleaned and sorted, pallet wood can be used in countless ways:

- Furniture: Shelves, coffee tables, headboards, and plant stands.

- Wall decor: Accent walls, picture frames, or geometric wall art.

- Garden projects: Raised beds, compost bins, or trellises.

- Crafts: Wooden signs, coasters, or drawer organizers.

Before final use, always sand the wood to remove roughness and potential splinters. For indoor applications, apply a non-toxic finish like tung oil or beeswax. Outdoor pieces benefit from weather-resistant sealants.

FAQ

Can I use power tools to speed up pallet disassembly?

Yes, but with caution. A reciprocating saw with a demolition blade can cut through nails quickly, but it sacrifices wood length. Use it only on damaged sections or when full planks aren’t needed.

Are pallet nails removable without breaking the wood?

Absolutely. By using proper leverage with a pry bar and supporting the board during removal, most planks come off intact. Nails are easier to extract once the board is slightly lifted.

Is pallet wood suitable for indoor furniture?

Only if it’s from a clean, HT-stamped source. Always sand thoroughly and apply a food-safe or low-VOC finish if used in kitchens or children’s spaces.

Checklist: Safe & Efficient Pallet Disassembly

- ☐ Confirm pallet is HT-treated (not MB)

- ☐ Wear safety goggles, gloves, and sturdy footwear

- ☐ Gather wrecking bar, hammer, nail puller, and saw

- ☐ Work on a soft or padded surface

- ☐ Pry boards slowly using leverage, not force

- ☐ Remove all nails and inspect for damage

- ☐ Sort wood by quality and intended use

- ☐ Sand and finish before final project assembly

Conclusion

Disassembling pallets isn’t just about saving money—it’s about resourcefulness, sustainability, and craftsmanship. With the right knowledge and tools, you transform overlooked industrial waste into functional, beautiful creations. Every plank rescued is a small victory for creativity and environmental responsibility.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?