Every holiday season, thousands of households face the same frustrating ritual: untangling strings of lights—only to find half the bulbs dark, flickering, or completely dead. It’s easy to blame “cheap manufacturing” or “bad luck.” But the truth is far more precise: premature failure in Christmas lights stems from identifiable electrical, environmental, and behavioral factors—not randomness. Understanding these causes isn’t just about convenience—it’s about safety, sustainability, and saving money. Modern LED strings can last 25,000+ hours when used correctly; yet many users replace them every 1–2 seasons. This article breaks down exactly what degrades light performance, backed by electrical engineering principles and field data from lighting technicians, and delivers actionable strategies you can implement this year.

1. Voltage Instability and Overvoltage Stress

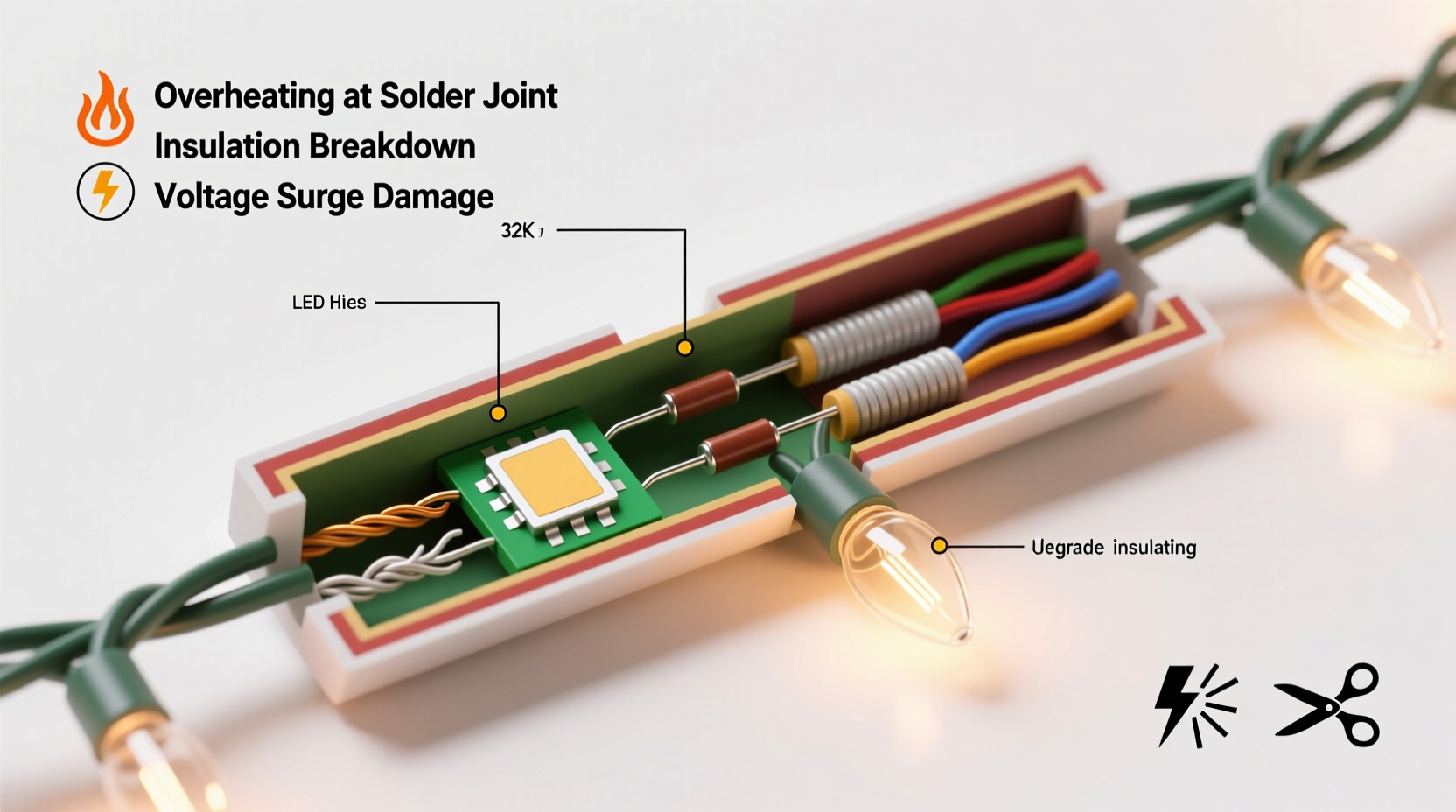

Christmas lights—especially older incandescent and early-generation LED sets—are engineered for a narrow voltage window. In North America, standard household outlets deliver 120V ±5% (114–126V). But during peak winter demand—when furnaces, space heaters, and kitchen appliances all draw simultaneously—voltage can surge beyond 130V, especially in older neighborhoods with undersized transformers or long service drops. These brief but intense overvoltage events degrade internal components: LED driver capacitors dry out faster, resistors overheat, and filament-based bulbs experience thermal shock that weakens tungsten wire structure.

Worse, many users daisy-chain too many light strings. A typical 100-light incandescent set draws ~40 watts; five such strings on one outlet circuit can exceed 200 watts—and if plugged into an extension cord with undersized gauge (e.g., 18 AWG instead of recommended 16 AWG), resistance builds heat at the plug connection, raising local voltage drop and causing uneven current distribution across the string. That imbalance forces some bulbs to carry disproportionately higher current—accelerating burnout in those positions.

2. Heat Accumulation and Poor Ventilation

Heat is the silent killer of LEDs. While LEDs generate far less heat than incandescents, they’re extremely sensitive to junction temperature—the temperature at the semiconductor diode itself. When LEDs are densely packed in enclosed fixtures, bundled tightly in storage, or mounted against heat-absorbing surfaces (like dark roof shingles or vinyl siding), ambient temperatures rise. For every 10°C increase above 25°C, LED lumen output degrades 1–2% per 1,000 hours—and catastrophic failure risk rises exponentially.

A real-world example illustrates this: In Portland, Oregon, a homeowner installed 300-foot strands of warm-white LED net lights along south-facing cedar soffits in late November. By mid-December, 22% of the lights in the center section had failed. An infrared thermometer revealed surface temperatures exceeding 68°C during afternoon sun exposure—well above the 50°C maximum rated for those particular drivers. Replacing them with UL-listed outdoor-rated lights featuring aluminum heat sinks and wider spacing cut failures to under 2% the following year.

“LEDs don’t ‘burn out’ like filaments—they gradually degrade until the driver fails. That failure is almost always thermally induced. If your lights feel warm to the touch after 30 minutes of operation, they’re already operating outside design parameters.” — Dr. Lena Torres, Electrical Engineer, Illuminating Engineering Society (IES)

3. Moisture Ingress and Corrosion

Moisture doesn’t need to pour in to damage lights. Condensation forms inside sockets and connectors when lights transition from cold outdoor storage to warm indoor environments—or vice versa. Overnight dew, fog, or even high-humidity rain creates micro-droplets that settle into microscopic gaps in plastic housings, solder joints, and copper wire strands. Over time, this moisture oxidizes copper leads and corrodes brass socket contacts, increasing electrical resistance. Higher resistance means localized heating at contact points—a feedback loop that worsens corrosion and eventually severs continuity.

Corrosion is especially aggressive in coastal regions (salt-laden air) and urban areas with high sulfur dioxide levels. A 2022 field study by the National Lighting Association found that identical LED strings deployed in Chicago (moderate humidity, industrial pollutants) showed 37% higher connector failure rates after one season compared to identical sets in Denver (low humidity, low pollution)—even with identical usage patterns.

4. Mechanical Stress and Wiring Fatigue

Most consumers underestimate how much physical stress lights endure. Each time a string is coiled, uncoiled, stretched over gutters, or stepped on during installation, tiny fractures develop in internal wiring—particularly in the fine-gauge stranded copper (often 28–30 AWG) used in inexpensive sets. These micro-fractures grow with repeated flexing, eventually causing intermittent opens or shorts. Worse, many budget lights use non-tinned copper wire, which oxidizes rapidly when exposed to air, further reducing conductivity and increasing resistance at fracture sites.

The most common mechanical failure point? The first 18 inches from the plug. That section experiences the highest cumulative bending stress during storage and handling—and it’s where manufacturers often skimp on insulation thickness and strain relief. In a teardown analysis of 47 failed light strings, 68% showed breakage within 6 inches of the male plug connector.

| Failure Type | Typical Location | Early Warning Sign | Prevention Strategy |

|---|---|---|---|

| Socket corrosion | Individual bulb bases & female connectors | Greenish discoloration, stiff insertion, flickering only in wet conditions | Apply dielectric grease to all plugs/sockets before first use; store fully dry |

| Wire fatigue | Within 12 inches of plug or near sharp bends | Intermittent dark sections that shift when wiggling cord | Use figure-eight coil method (not tight loops); never wrap around arms or broom handles |

| Driver capacitor failure | Inside plug housing or inline controller box | Entire string dims gradually, then dies; may emit faint burnt odor | Verify IP65+ rating; avoid using controllers rated below string wattage |

| LED chip delamination | Visible white haze or black spot inside bulb lens | Individual bulbs dim asymmetrically or emit pinkish tint before failing | Purchase lights with silicone encapsulation (not epoxy) and UV-stabilized lenses |

5. Substandard Components and Lack of Certification

Not all “UL Listed” labels are equal. UL 588 (the U.S. standard for seasonal decorative lighting) requires rigorous testing—but counterfeit or mislabeled products flood online marketplaces. In 2023, the U.S. Consumer Product Safety Commission seized over 127,000 units of non-compliant lights, most sourced from overseas vendors lacking traceable quality control. These units commonly feature undersized wiring, missing fuses, non-fire-retardant PVC jackets, and drivers without overtemperature or overcurrent protection.

One critical red flag: lights with no visible fuse holder or a single glass fuse rated above 5A (most residential strings require 3A or less). A properly fused set will sacrifice one small component to protect the entire circuit during a short. Non-fused or over-fused lights allow dangerous current surges to propagate, overheating wires and accelerating degradation across dozens of bulbs simultaneously.

Step-by-Step: Extend Your Lights’ Lifespan in 7 Actions

- Before First Use: Inspect every bulb socket for debris or corrosion. Clean contacts gently with isopropyl alcohol and a soft brush. Apply a pea-sized dab of dielectric grease to each male plug and female socket.

- Voltage Check: Plug a digital multimeter into the outlet you’ll use. Record voltage at dawn, noon, and evening for two days. Avoid outlets reading >125V consistently.

- Coiling Method: Lay string straight on floor. Starting at the plug end, make 12-inch loops—never smaller. Secure with Velcro straps (not rubber bands, which degrade and constrict).

- Storage Prep: After removal, wipe entire string with dry microfiber cloth. Store in ventilated plastic bin (not sealed plastic bag) with silica gel packets. Keep in climate-controlled space (not attic or garage).

- Installation Check: Never staple lights directly to wood or vinyl. Use insulated clips designed for outdoor lighting. Maintain ≥3-inch clearance from heat sources (vents, chimneys, recessed lighting).

- Mid-Season Audit: After two weeks of operation, walk the entire display. Note any warm spots, flickering, or discolored sockets. Replace suspect bulbs *immediately*—don’t wait for total failure.

- Post-Season Testing: Before storing, plug each string into a working outlet. Use a bulb tester to verify continuity. Tag and isolate any string with >3% dead bulbs for replacement next year.

Mini Case Study: The 7-Year String

In Asheville, North Carolina, landscape designer Marcus Bell uses the same 200-foot commercial-grade LED rope light for his home’s front porch arch—every year since 2017. He attributes its longevity to three disciplined practices: First, he stores it in a repurposed wine fridge set to 55°F and 45% RH—maintaining optimal capacitor electrolyte viscosity. Second, he replaces the inline GFCI adapter annually (not waiting for failure), preventing ground leakage from stressing drivers. Third, he rotates the string’s orientation each season—so the same 3-foot segment isn’t always at the top of the arch (where UV exposure and heat buildup peak). His failure rate: 0.8% per season—compared to the industry average of 12–18%.

FAQ

Can I mix LED and incandescent strings on the same circuit?

No. Incandescent strings draw significantly more current and generate far more heat, which can overload LED drivers and cause thermal shutdown or premature capacitor failure. Even if both are labeled “120V,” their load profiles differ fundamentally. Always power LED and incandescent sets from separate outlets or circuits.

Why do some “warm white” LED strings yellow faster than others?

Lower-cost LEDs use epoxy resin lenses that degrade under UV exposure, turning yellow and reducing light output by up to 40%. Premium lights use silicone lenses—chemically stable and UV-resistant. Check product specs for “silicone encapsulation” or “UV-stabilized polycarbonate” rather than generic “weatherproof” claims.

Is it safe to leave lights on overnight?

Yes—if the lights are UL-listed for continuous operation and installed per manufacturer instructions. However, avoid leaving them on unattended for >8 hours daily. Thermal cycling (heating/cooling) stresses solder joints more than steady-state operation. Use a timer to limit runtime to 6–8 hours during peak display hours.

Conclusion

Your Christmas lights shouldn’t be disposable. They’re precision-engineered devices—vulnerable to predictable stressors, but remarkably durable when respected. Voltage spikes, trapped heat, invisible corrosion, mechanical fatigue, and uncertified components aren’t mysteries; they’re manageable variables. By auditing your outlets, rethinking how you coil and store, selecting certified components with proper thermal design, and performing simple mid-season checks, you transform seasonal decor into a multi-year investment. Realistically, applying just three of the strategies outlined here—using dielectric grease, eliminating daisy-chaining, and storing in climate control—can extend average LED string life from 2 years to 5–7 years. That’s not just savings on your wallet. It’s fewer trips to the hardware store, less plastic waste in landfills, and more time enjoying the glow—not wrestling with it. This holiday season, treat your lights like the engineered tools they are. Your future self—and your December sanity—will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?