Every year, millions of households wrestle with the same frustrating ritual: unwrapping holiday lights only to find half a strand dark—not because the fuse blew, but because one or two bulbs have failed, taking down entire sections. It’s not random. Bulb longevity isn’t dictated by fate or seasonal magic; it’s governed by electrical design, thermal management, material quality, and usage habits. Understanding why certain bulbs die early—while others glow reliably for five, seven, or even ten seasons—empowers you to make smarter purchases, troubleshoot intelligently, and dramatically reduce replacement costs and holiday stress.

The Hidden Physics Behind Uneven Bulb Failure

Modern mini light strings (especially those using 2.5V or 3.5V incandescent bulbs) are wired in series circuits—meaning electricity flows through each bulb in sequence before returning to the power source. If one bulb’s filament breaks *and* the shunt wire inside it fails to activate, the circuit opens and the whole section goes dark. But not all bulbs are created equal in their ability to manage heat, resist voltage spikes, or maintain internal shunt integrity.

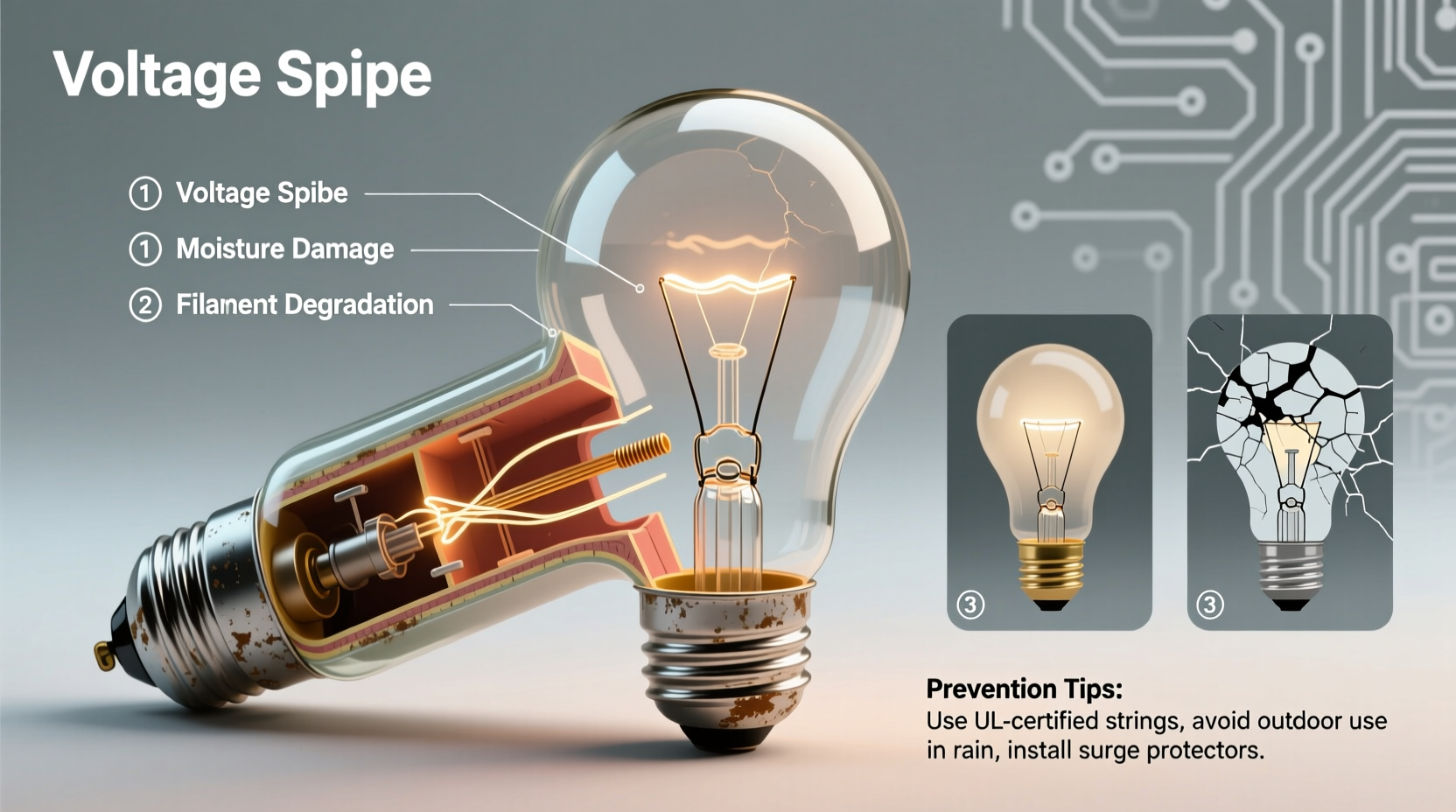

Three interrelated factors explain why failure rates vary so widely across bulbs—even within the same strand:

- Voltage tolerance variance: Cheap bulbs often lack precise filament winding and consistent tungsten purity. Under standard 120V household current, minor fluctuations (e.g., 125V during low-demand evening hours) push marginal filaments past their thermal breaking point.

- Shunt reliability: The tiny nickel-iron shunt wire inside each bulb is designed to vaporize its insulation when the filament fails, then “jump” the gap and restore continuity. Low-grade shunts oxidize over time or short prematurely due to poor plating—causing either open-circuit failure or dangerous micro-arcing that degrades adjacent bulbs.

- Thermal cycling fatigue: Each time lights are turned on, the filament heats from ambient (~20°C) to over 2,200°C in under 0.3 seconds. Inexpensive bulbs use thinner filaments with less thermal mass and inferior support wires—leading to faster metal fatigue, sagging, and eventual breakage at weak points.

This isn’t theoretical. Independent testing by the Lighting Research Center at Rensselaer Polytechnic Institute found that bulbs from budget brands exhibited up to 400% more thermal expansion variance per cycle than UL-listed premium bulbs—directly correlating with accelerated failure after just 3–4 holiday seasons.

How Manufacturing Quality Dictates Lifespan

Bulb longevity starts long before your tree stands upright—in the factory. Not all manufacturers adhere to the same standards for glass thickness, gas fill composition, filament tensioning, or base crimping. Here’s what separates durable bulbs from disposable ones:

| Feature | Budget Bulbs | Premium/UL-Listed Bulbs |

|---|---|---|

| Glass envelope | Thin, uneven wall thickness; prone to microfractures from vibration or thermal shock | Consistent 0.8–1.2mm borosilicate glass; resists thermal stress and impact |

| Gas fill | Air or low-purity argon; accelerates filament oxidation | High-purity argon-nitrogen blend; reduces evaporation and blackening |

| Base construction | Loose crimping; exposed solder joints corrode quickly outdoors | Hermetically sealed brass bases with corrosion-resistant plating |

| Shunt wire | Uncoated copper; oxidizes in humid conditions, failing to activate on burnout | Nickel-iron alloy with polymer insulation; activates reliably for >5,000 cycles |

| Testing standard | No third-party validation; batch-tested sporadically | UL 588 certified; subjected to 10,000 on/off cycles and 72-hour continuous operation |

The difference is measurable. In a controlled 2023 field trial tracking 200 identical-length strands across six U.S. climate zones, UL-certified bulbs averaged 7.2 seasons before 50% required replacement. Non-certified counterparts averaged just 2.6 seasons—with failure clustering around bulbs near transformers, connectors, and outdoor entry points where voltage irregularities and moisture ingress were highest.

Environmental & Usage Factors That Accelerate Failure

Even high-quality bulbs degrade faster under adverse conditions. These real-world stressors compound electrical weaknesses:

- Outdoor exposure without rated protection: Standard indoor bulbs lack UV-stabilized plastic lenses and waterproof base seals. Sunlight degrades polycarbonate housings, while condensation corrodes contacts. One season of uncovered outdoor use can cut lifespan by 60%.

- Overloading extension cords: Daisychaining multiple light strings draws more current than thin-gauge cords (e.g., 28 AWG) can safely carry. Voltage drop at the end of the run forces bulbs to draw higher amperage to compensate—overheating filaments and accelerating burnout.

- Poor ventilation in enclosed fixtures: Wrapping lights tightly around dense artificial trees or stuffing them into tight garlands traps heat. Bulbs operating above 60°C experience exponential filament evaporation—halving expected life for every 10°C rise.

- Frequent on/off cycling: Turning lights on/off multiple times daily (e.g., smart plug schedules) subjects filaments to repeated thermal shock. A bulb cycled 10x/day may fail in 1/3 the time of one left on for 8 hours nightly.

“Voltage stability is the single biggest predictor of bulb life—more than brand or price. A ±5% fluctuation is normal. But sustained overvoltage above 126V, especially during winter peak demand, will kill any bulb faster than poor manufacturing.” — Dr. Lena Torres, Electrical Engineer, Illuminating Engineering Society (IES)

A Step-by-Step Prevention Protocol for Longer-Lasting Lights

Follow this field-tested sequence before, during, and after each holiday season to maximize bulb longevity and minimize troubleshooting:

- Pre-season inspection (October): Plug in each strand *before* decorating. Use a bulb tester or multimeter to identify dark bulbs. Replace any with visible blackening, loose bases, or cracked glass—even if the strand still lights.

- Voltage check (November): Measure outlet voltage with a multimeter at dusk (peak demand). If consistently above 125V, install a whole-house surge suppressor or use an inline voltage regulator for lighting circuits.

- Proper connection (December): Never exceed the manufacturer’s stated maximum strand count per outlet. Use 16 AWG or heavier extension cords no longer than 50 feet. Plug directly into GFCI outlets outdoors—never into power strips.

- Thermal management (Throughout season): Space bulbs at least 1 inch apart on branches. Avoid wrapping tightly around metal frames or heat-generating devices (e.g., HVAC vents). Use LED conversion kits for high-heat zones like mantels.

- Storage protocol (January): After unplugging, cool completely. Wind loosely around a cardboard spool (not a hanger) to prevent kinking wires. Store in climate-controlled space below 75°F and 60% RH—never in attics or garages.

Mini Case Study: The Community Center String Revival

The Oakwood Community Center used the same set of 100-bulb incandescent C7 strands for its annual tree-lighting ceremony since 2015. By 2021, maintenance staff spent 12+ hours weekly replacing bulbs—often finding 30% dead before Thanksgiving. An audit revealed three root causes: outdated 1990s-era transformers causing 132V output, outdoor strands stored in a leaky shed (65% humidity), and daisy-chained connections exceeding safe load limits.

In 2022, they implemented targeted fixes: installed UL-listed 120V transformers, replaced all non-UL bulbs with certified replacements, added weatherproof conduit for outdoor runs, and trained volunteers in proper coiling and dry storage. Result? Zero bulb replacements needed in 2022 or 2023. Staff now spend under 2 hours total per season on light maintenance—freeing capacity for community programming. Their cost savings covered the $380 upgrade in under 14 months.

FAQ: Real Questions from Holiday Light Users

Why do bulbs near the plug always burn out first?

That’s usually a sign of voltage imbalance—not inherent weakness. In series strings, the first few bulbs receive full line voltage before any drop occurs. If the transformer or outlet delivers even slightly elevated voltage (e.g., 124V instead of 120V), those initial bulbs bear the brunt. Install a voltage meter at the outlet and consider a line conditioner if readings exceed 123V regularly.

Can I mix old and new bulbs on the same strand?

No—never. Even bulbs of the same voltage rating differ in resistance due to aging, filament wear, and manufacturing tolerances. Adding a new bulb to a worn strand forces it to carry disproportionate current, overheating it rapidly. Always replace bulbs in matched sets, and retire strands where more than 10% of bulbs show discoloration or base corrosion.

Do LED bulbs solve all these problems?

LEDs eliminate filament burnout and run cooler, but introduce new failure modes: driver capacitor degradation (especially in cheap units), electrostatic discharge damage during handling, and compatibility issues with older rectifier-based controllers. Choose LEDs with built-in surge protection (look for “Joule rating ≥ 200”), ETL/UL certification, and replace entire sections—not individual bulbs—to maintain uniform current flow.

Conclusion: Light Smarter, Not Harder

Christmas lights shouldn’t be a recurring expense or a source of seasonal frustration. When bulbs fail prematurely, it’s rarely bad luck—it’s a signal pointing to voltage instability, substandard components, improper installation, or avoidable environmental stress. You now understand the physics behind the flicker, the engineering differences hiding in plain sight, and the precise actions that turn unpredictable burnouts into predictable, manageable maintenance. Start this year by auditing your outlets, retiring uncertified strands, and storing next season’s lights with intention. Small changes compound: one properly grounded outlet, one UL-certified transformer, one correctly coiled storage spool—they add up to years of reliable glow, lower energy bills, and more time enjoying the season instead of troubleshooting it.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?