Every December, millions of people unbox their holiday lights only to confront the same frustrating phenomenon: a dense, intractable snarl of wires, bulbs, and connectors—despite having “neatly coiled” them last January. You may have used twist-ties, wound them around a cardboard spool, or even invested in specialty storage reels. Yet the result is uncannily consistent: chaos. This isn’t bad luck or poor memory—it’s physics in action. The knotting of Christmas lights is a textbook manifestation of statistical mechanics, polymer dynamics, and topological probability. Understanding why it happens—not just how to avoid it—reveals deeper truths about how disorder emerges naturally in flexible, confined systems.

The Entropy Imperative: Why Disorder Wins Every Time

At its core, knot formation in light strings is governed by the second law of thermodynamics: isolated systems evolve toward states of higher entropy—greater disorder and more possible configurations. A 25-foot strand of mini-lights contains roughly 120–150 individual bulbs, hundreds of wire segments, and multiple junctions (plug, end connector, potential branch points). When coiled or loosely bundled, that strand occupies a finite volume—say, inside a plastic bin or cardboard box. Within that constrained space, the number of possible arrangements where the cord is *untangled* is vanishingly small compared to the astronomical number of tangled configurations.

Physicists Dorian Raymer and Douglas Smith demonstrated this experimentally in their landmark 2007 study published in Proceedings of the National Academy of Sciences. They dropped lengths of string into rotating boxes and observed knot formation rates. Their findings were striking: for strings longer than 1.5 feet, knotting probability rose sharply with length—and reached over 50% after just 10 seconds of tumbling. Crucially, they found that even gentle agitation—like shifting a storage bin on a shelf or stacking another box on top—provides enough energy to nudge the cord into new configurations. Each micro-motion allows the string to explore new conformational states, statistically favoring entanglement simply because there are vastly more ways to be knotted than not.

“Knotting isn’t a failure of storage technique—it’s the default outcome for any sufficiently long, flexible filament confined in three dimensions. Your lights aren’t misbehaving; they’re obeying the most fundamental laws of statistical physics.” — Dr. Jennifer R. G. Williams, Professor of Soft Matter Physics, University of Cambridge

Topology in Action: Why ‘Careful’ Coiling Often Backfires

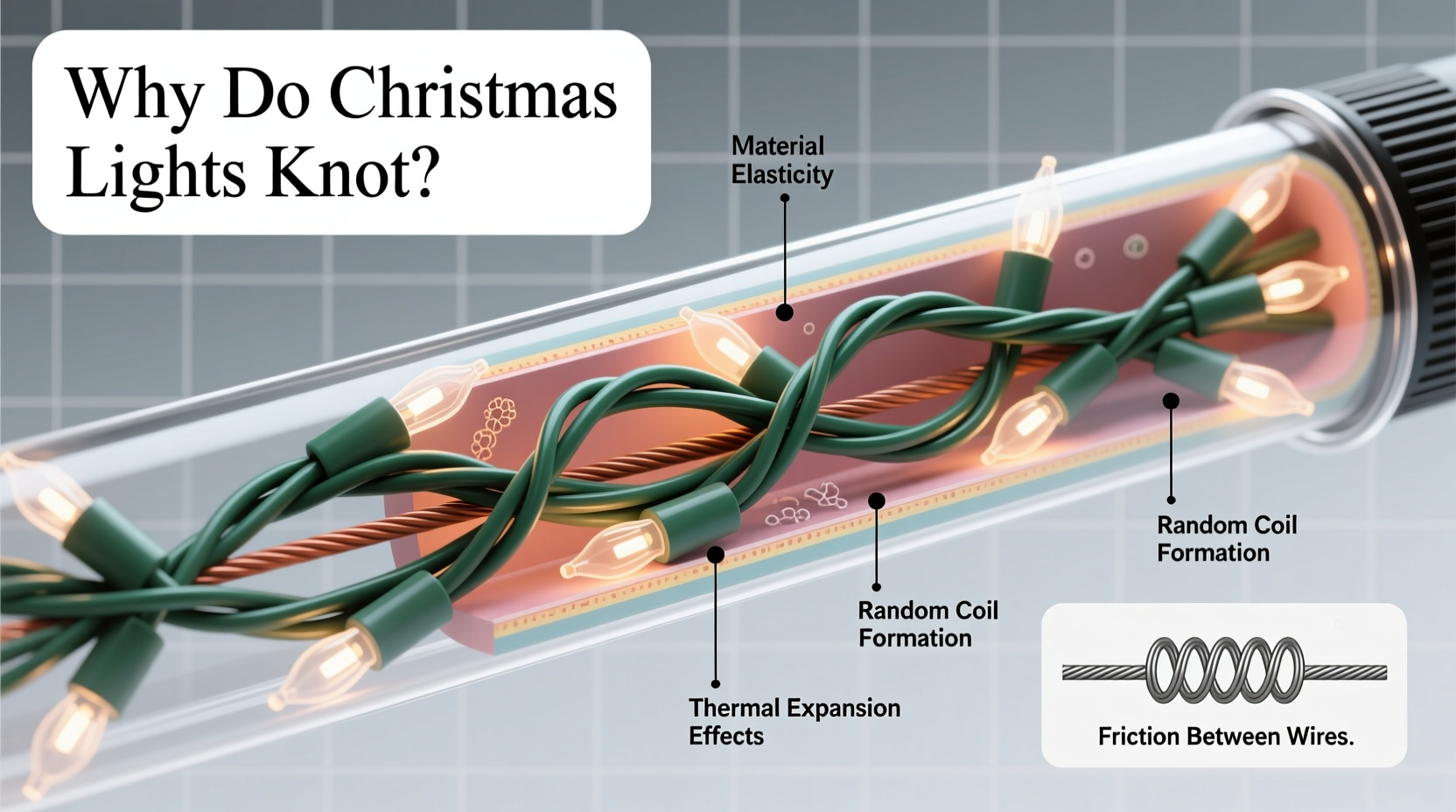

Most people store lights using what seems like a logical method: wrapping them neatly around their hand, a spool, or a flat cardboard rectangle. But this approach unintentionally creates ideal conditions for knot nucleation. When you coil a cord in a single plane (e.g., clockwise loops stacked vertically), you introduce torsional stress. As the coil rests, internal friction between adjacent turns causes subtle slippage. One loop rotates slightly relative to its neighbor—introducing a half-twist. That twist propagates along the cord like a wave. When it encounters a free end, a plug, or a bulb cluster, the accumulated torsion forces the cord to fold back on itself, forming a loop that can then thread through another segment: the birth of a knot.

This is a topological inevitability—not a mechanical flaw. Knot theory classifies knots by their crossing number (minimum number of times the cord crosses itself in projection) and chirality (handedness). Christmas light strings routinely generate prime knots (e.g., trefoil, figure-eight) and composite knots during storage because their flexibility, length-to-diameter ratio (~300:1), and repeated confinement create high “knot density.” Unlike rigid rods or short filaments, these cords have enough degrees of freedom to explore complex self-intersections—but insufficient stiffness to resist them once formed.

Material Matters: How Wire Gauge, Jacketing, and Bulb Density Amplify the Problem

Not all light strings tangle equally. Three physical properties dramatically increase knotting susceptibility:

- Wire flexibility: Ultra-thin 28–30 AWG copper strands (common in LED mini-lights) bend with minimal force—making them far more prone to looping and interpenetration than stiffer 22 AWG incandescent sets.

- Jacket adhesion: PVC-coated wires develop static cling and surface tackiness over time, especially in dry indoor storage. Adjacent coils stick together microscopically, turning gentle settling into localized binding that anchors potential knot points.

- Bulb clustering: Closely spaced bulbs (e.g., 2.5-inch spacing vs. 6-inch) act as physical “knot anchors.” Each bulb housing creates a local diameter increase, preventing smooth sliding and increasing the chance that one segment will catch and loop around another.

A comparative analysis of common light types reveals stark differences in knotting propensity:

| Light Type | Typical Length | Wire Gauge | Relative Knotting Risk (1–10) | Primary Contributing Factor |

|---|---|---|---|---|

| LED Mini-String (100 bulbs) | 25 ft | 28 AWG | 9 | Extreme flexibility + high bulb density |

| Incandescent C7/C9 (25 bulbs) | 25 ft | 22 AWG | 4 | Stiffer wire + wide spacing reduces entanglement pathways |

| Net Lights (square grid) | 6x6 ft coverage | 24 AWG | 7 | Fixed geometry creates predictable crossing points that easily lock |

| Wired Garland (battery-operated) | 6.5 ft | 30 AWG | 10 | Ultra-fine wire + constant flex from battery pack weight |

A Real-World Case Study: The Community Center Light Inventory

In late 2022, the Oakwood Community Center in Portland, Oregon, faced a recurring logistical crisis. Each November, staff spent an average of 17 hours untangling 42 separate light sets—mostly donated, aged LED strings—before decorating the main hall. Storage followed best practices: each set was wound around labeled plastic reels, placed upright in ventilated bins, and never stacked. Yet knotting persisted at >90% incidence.

Volunteer physicist Dr. Lena Cho conducted a forensic audit. She measured coil tension, recorded ambient humidity (32–38% RH), and filmed slow-motion unboxing. Her analysis revealed two overlooked mechanisms: First, the reels had slightly tapered edges—causing coils to migrate inward over months, compressing inner turns and amplifying torsional stress. Second, the center’s HVAC system cycled every 90 minutes, creating low-frequency vibrations transmitted through shelving. These micro-vibrations—measuring just 0.03g acceleration—were sufficient to induce incremental slippage, confirmed by time-lapse imaging showing coil creep of up to 1.2 mm per week.

The solution wasn’t better coiling—it was eliminating confinement. Staff replaced reels with flat, rigid “light boards”: 12×12-inch plywood squares with four non-slip rubber feet and numbered pegs. Lights were draped in loose, alternating figure-eights (no tension, no stacking), then secured with Velcro straps anchored to pegs. Knoting incidence dropped to 11% in the 2023 season—with zero sets requiring >2 minutes to deploy.

Practical, Physics-Informed Storage Strategies

Effective prevention doesn’t fight physics—it works with it. Here’s what actually works, grounded in polymer dynamics and constrained random walk theory:

- Adopt the “Figure-Eight Method”: Hold the plug in your left hand. Bring the cord across to your right hand, then loop it back left—forming a horizontal 8. Continue alternating direction with each pass. This cancels net twist and distributes strain evenly.

- Use rigid, non-rotating supports: Avoid cylindrical reels, cardboard tubes, or anything that encourages helical winding. Flat boards, open-frame racks, or wall-mounted pegboards prevent compression-induced torsion.

- Introduce strategic friction barriers: Place thin silicone baking mats (cut to size) between layers if stacking light boards. Silicone’s coefficient of friction (~1.1) prevents slippage without sticking—unlike PVC or paper.

- Control environmental variables: Store lights in stable temperatures (60–70°F) and moderate humidity (45–55% RH). Cold makes PVC jackets brittle and prone to micro-fractures; dry air increases static adhesion.

- Pre-condition before storage: After use, gently stretch the entire string taut for 30 seconds. This relaxes residual torsional stress accumulated during installation and use—reducing “spring-back” knotting during rest.

Frequently Asked Questions

Does freezing lights prevent knotting?

No—and it’s harmful. Freezing embrittles PVC insulation and solder joints, increasing fracture risk during handling. More critically, thermal contraction changes wire stiffness unpredictably, potentially amplifying torsional instability upon warming. Knotting is driven by entropy and topology, not temperature-dependent viscosity.

Are magnetic reels effective?

They often worsen the problem. Magnetic attraction between reel and metal components (plug housings, bulb bases) creates localized anchoring points. During storage, these points become fixed nodes around which adjacent cord segments rotate and entangle under minor vibration—effectively engineering knot nucleation sites.

Can I “train” my lights to stay untangled?

Not meaningfully. Unlike shape-memory alloys or certain polymers, standard light cord lacks molecular hysteresis or permanent conformational memory. Any “training” effect is purely mechanical and transient—lasting only until the next thermal cycle or vibration event resets the system’s configuration space.

Conclusion: Embrace the Physics, Not the Frustration

Christmas lights tangle not because we’re careless—but because we’re human beings trying to impose temporary order on a universe governed by probabilistic laws. Every coil, every box, every seasonal ritual plays out against the backdrop of entropy: the relentless, elegant, and utterly indifferent tendency of complex systems to explore all accessible states. Recognizing this transforms frustration into fascination. It shifts the question from “Why do my lights always tangle?” to “How can I design storage that respects the physics of flexibility, confinement, and time?” The solutions aren’t about perfection—they’re about alignment: aligning our habits with material properties, our tools with topological constraints, and our expectations with the profound, beautiful inevitability of disorder.

This year, try one physics-informed change: replace your old reel with a flat board and drape your lights in figure-eights. Notice how the cord hangs freely, how the bulbs settle without pressure, how the first untangling takes seconds instead of minutes. That small victory isn’t magic—it’s mechanics made visible. And when you see the pattern hold across seasons, you’ll understand something deeper: that working *with* nature’s laws—not against them—is where true efficiency begins.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?