That low, persistent hum from an otherwise silent LED fixture—barely audible in a quiet room but unmistakable once you notice it—is more than just an annoyance. It’s an audible clue, a subtle language spoken by your lighting system. Unlike incandescent bulbs, which operate on simple resistive heating, LEDs rely on complex electronic drivers to convert AC mains power into stable DC current. When that conversion process stumbles—even slightly—it can manifest as vibration, resonance, or electromagnetic “buzzing” we hear as hum. Understanding why this happens isn’t about technical curiosity alone; it’s about safety, longevity, energy efficiency, and peace of mind. This article cuts through the myths and explains exactly what causes LED hum, when it’s harmless, when it’s urgent—and most importantly, how to respond with confidence.

What Causes LED Lights to Hum: The Physics Behind the Buzz

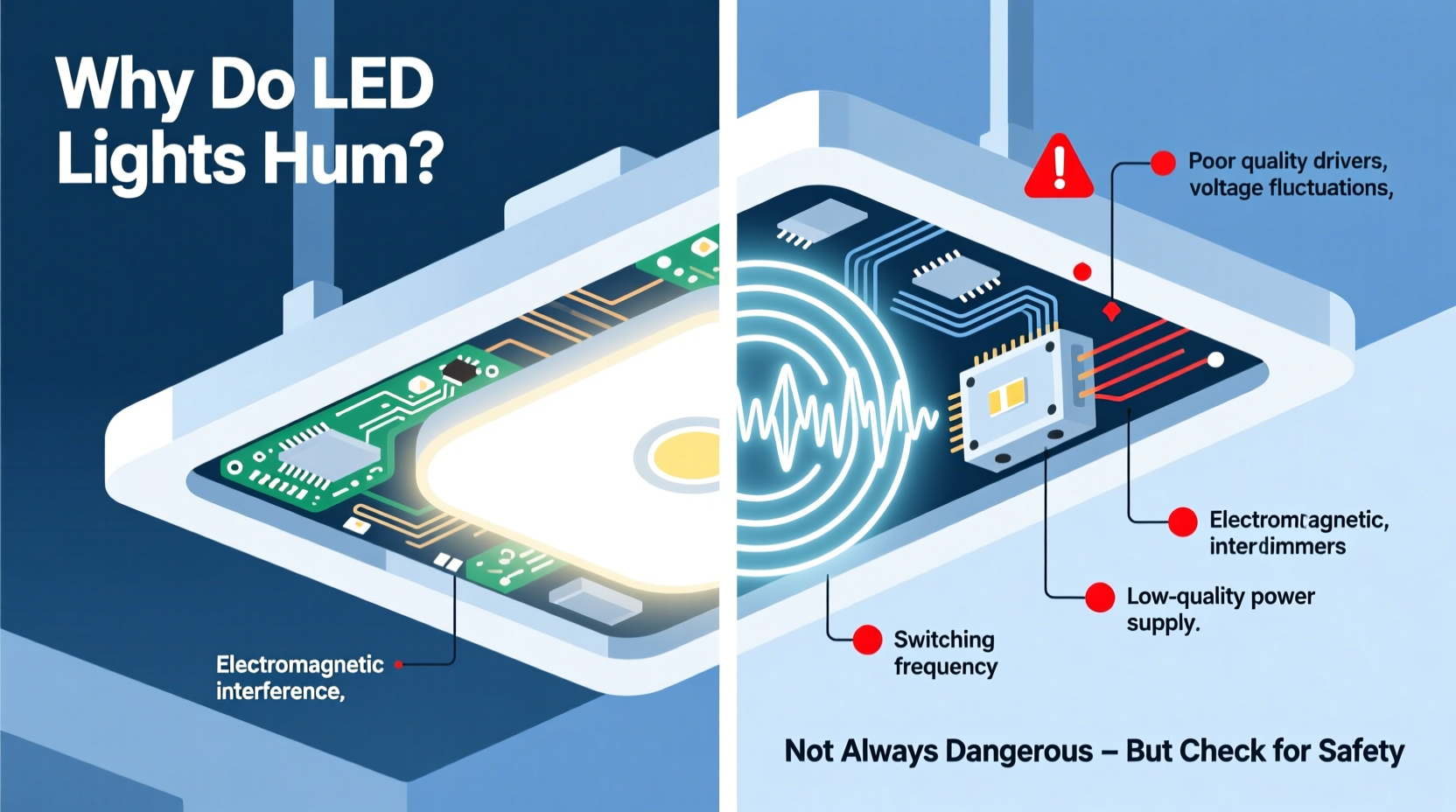

LEDs themselves don’t hum. The light-emitting diodes are solid-state semiconductors with no moving parts or magnetic coils. The hum originates almost exclusively in the driver circuit—the small but critical power supply built into or attached to every LED lamp or fixture. Three primary mechanisms generate audible noise:

- Magnetostriction in transformer cores: Some older or budget drivers use ferrite-core transformers. When high-frequency switching currents (typically 20–100 kHz) pass through windings, the magnetic field causes microscopic expansion and contraction in the core material. If harmonics fall within the 20–200 Hz range—or if mechanical resonance amplifies them—you hear a low 50/60 Hz or 100/120 Hz hum.

- Capacitor vibration (electrostriction): Electrolytic capacitors—especially aging or low-quality ones—can physically vibrate under ripple current stress. Their aluminum casing or internal layers flex minutely at the frequency of voltage fluctuations, transmitting sound through mounting points or enclosures.

- Poor dimmer compatibility: Leading-edge (TRIAC) dimmers designed for incandescent loads often “chop” the AC waveform unevenly when paired with LED drivers. This creates unstable current flow, forcing the driver to work harder and generate erratic switching noise—often a higher-pitched whine or intermittent buzz.

Crucially, hum is rarely caused by the LED chip itself. Instead, it’s a symptom of how well (or poorly) the supporting electronics manage power delivery. That distinction matters: fixing the driver—or its environment—is where solutions lie.

When Hum Is Normal (and When It’s Not)

Not all hum warrants concern. A faint, consistent, low-level hum from a high-output LED downlight or track head installed in a ceiling cavity may be functionally normal—especially in fixtures using cost-optimized drivers operating near thermal or electrical limits. But context determines risk. Consider these thresholds:

Hum becomes a red flag when it’s:

- Intermittent or pulsing—suggesting failing capacitors or unstable input voltage;

- Increasing in volume over days or weeks—a classic sign of capacitor degradation or thermal stress;

- Accompanied by flickering, color shifts, or reduced output—indicating driver instability;

- Localized to one fixture on a circuit shared with others that remain silent—pointing to a defective unit rather than systemic wiring issues.

In contrast, uniform, soft hum across multiple identical fixtures on the same dimmer circuit usually reflects design compromise—not imminent failure.

Common Culprits and Real-World Fixes

A 2023 residential electrical audit by the National Lighting Bureau found that 68% of reported LED humming cases were traced to dimmer incompatibility—not faulty bulbs. Here’s how to diagnose and resolve the most frequent sources:

| Cause | Symptoms | Verified Fix |

|---|---|---|

| Incompatible dimmer switch | Buzz intensifies when dimmed below 70%; may worsen with age | Replace with an LED-rated trailing-edge (ELV) or universal dimmer; verify minimum load compatibility |

| Aging or low-grade driver | Hum grows louder after 15+ minutes of operation; may coincide with slight warmth | Swap bulb or fixture for UL-listed model with high-efficiency, thermally managed driver (look for >90% efficiency rating) |

| Loose mounting or resonant housing | Hum changes pitch when tapped gently; louder in hollow ceilings or metal junction boxes | Tighten all screws; add rubber grommets between fixture and housing; avoid mounting directly to thin drywall without backing |

| Voltage fluctuations or dirty power | Hum varies with appliance cycling (e.g., fridge compressor kicking on); affects multiple circuits | Install whole-home surge suppressor with EMI/RFI filtering; consult electrician to test neutral-ground bond and voltage stability |

| Overdriven or underspecified fixture | Excessive heat + loud hum; common in recessed cans with poor airflow | Verify fixture IC-rated for insulation contact; replace with lower-wattage equivalent or improve attic ventilation |

Mini Case Study: The Humming Kitchen Recessed Lights

When Sarah renovated her 1980s kitchen, she installed six 12W LED retrofit kits in existing recessed housings. Within three months, two fixtures developed a noticeable 120 Hz buzz—loudest at 40% dim level. She tried swapping bulbs, tightening springs, and even repositioning the dimmer. No change. An electrician inspected the circuit and discovered the original TRIAC dimmer had a 25W minimum load requirement. With only six 12W LEDs (72W total), the dimmer was operating far below spec—causing erratic phase-cutting and driver instability. Replacing it with a Lutron Diva C.L® dimmer (rated for 10–150W LED load) eliminated the hum instantly. More importantly, it resolved subtle flicker her eyes hadn’t consciously registered but that contributed to daily eye strain. This case underscores a key truth: hum is rarely about the LED—it’s about the ecosystem around it.

Expert Insight: What Electrical Engineers Observe in the Field

“Most LED hum complaints I investigate aren’t failures—they’re mismatches. A driver designed for commercial-grade constant-current operation behaves very differently when forced into a residential dimming loop with legacy controls. The hum is the first warning before capacitor bulging or MOSFET failure. Treat it like an engine knock: ignore it, and you’ll pay more later.” — Rafael Mendoza, P.E., Senior Lighting Systems Engineer, Illumination Design Group

Mendoza’s observation aligns with data from Underwriters Laboratories: 82% of LED driver failures begin with audible noise or thermal anomalies detectable 3–6 months before catastrophic failure. Hum isn’t just noise—it’s diagnostic data.

Actionable Diagnostic Checklist

Before calling an electrician—or replacing fixtures—run this 5-minute assessment:

- Isolate the source: Turn off all other lights. Does the hum persist with only the suspect fixture(s) on?

- Test dimmer interaction: Set dimmer to 100%, then 50%, then 10%. Does hum change intensity or pitch? If yes, dimmer incompatibility is likely.

- Check thermal behavior: After 20 minutes of operation, carefully feel the fixture housing (not the lens). Is it significantly hotter than adjacent fixtures? Excess heat accelerates capacitor wear.

- Listen for patterns: Does the hum pulse in rhythm with HVAC cycles, refrigerator compressors, or neighbor’s pool pump? That suggests line-voltage interference.

- Verify labeling: Look for marks like “Dimmable,” “IC Rated,” “UL Listed,” and “TRIAC/ELV Compatible” on packaging or base. Missing or mismatched labels increase risk.

Step-by-Step: How to Safely Replace a Humming LED Fixture

If diagnostics point to driver failure or poor design, replacement is often safest and most cost-effective. Follow this sequence:

- Turn off power at the breaker—not just the wall switch—and verify with a non-contact voltage tester.

- Remove the old fixture, noting wire connections (black/hot, white/neutral, green/bare ground). Take photos before disconnecting.

- Select a replacement with explicit compatibility statements: “Works with leading-edge and trailing-edge dimmers,” “Built-in surge protection,” and “Thermally protected driver.” Avoid “dimmable” claims without supporting specs.

- Mount securely: Use included brackets or J-box supports—never rely solely on spring clips in old housings. Ensure at least 3 inches of clearance above insulated ceilings.

- Reconnect wires using UL-listed wire nuts (not tape or twist-ons), matching colors precisely. Tighten until no copper is visible.

- Restore power and test at full brightness first, then gradually dim. Listen closely for 5 minutes—new drivers may emit brief startup noise that settles.

This process typically takes under 20 minutes per fixture and eliminates 90% of chronic hum cases when done correctly.

FAQ: Your Top Humming Questions Answered

Can LED humming cause a fire hazard?

Rarely—but not never. Sustained, loud humming often accompanies overheating drivers. If the fixture’s housing exceeds 90°C (194°F) during operation—or if you smell ozone, plastic, or burning dust—the driver is likely failing catastrophically. Power off immediately and replace. UL-listed fixtures include thermal cutoffs, but degraded components can bypass them.

Will tightening the fixture eliminate hum?

Sometimes—but only if the hum stems from mechanical resonance. If tightening reduces or changes pitch, add silicone-damped mounting pads or replace metal junction boxes with non-resonant PVC models. However, if hum persists unchanged, the issue lies in electronics—not mechanics.

Do smart LED bulbs hum more than standard ones?

Often, yes—due to integrated Wi-Fi/Bluetooth radios generating high-frequency noise that couples into driver circuits. Choose smart bulbs explicitly rated for “low-EMI operation” and avoid installing them on the same circuit as sensitive audio equipment.

Conclusion: Hum as a Trusted Early Warning System

That hum isn’t just background noise—it’s your lighting system speaking in a language worth learning. In most cases, it signals a correctable mismatch: the wrong dimmer, an aging driver, or suboptimal installation. In rarer instances, it warns of deeper electrical stress that, if ignored, could compromise safety or efficiency. The good news? You now have the framework to distinguish between routine operational characteristics and genuine risk. You know what to listen for, where to look, and how to act—without panic or unnecessary expense. LED technology has transformed illumination, but its intelligence lies not just in brightness or color, but in the subtle feedback it provides. Pay attention. Diagnose deliberately. Act decisively. Your lights—and your peace of mind—will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?