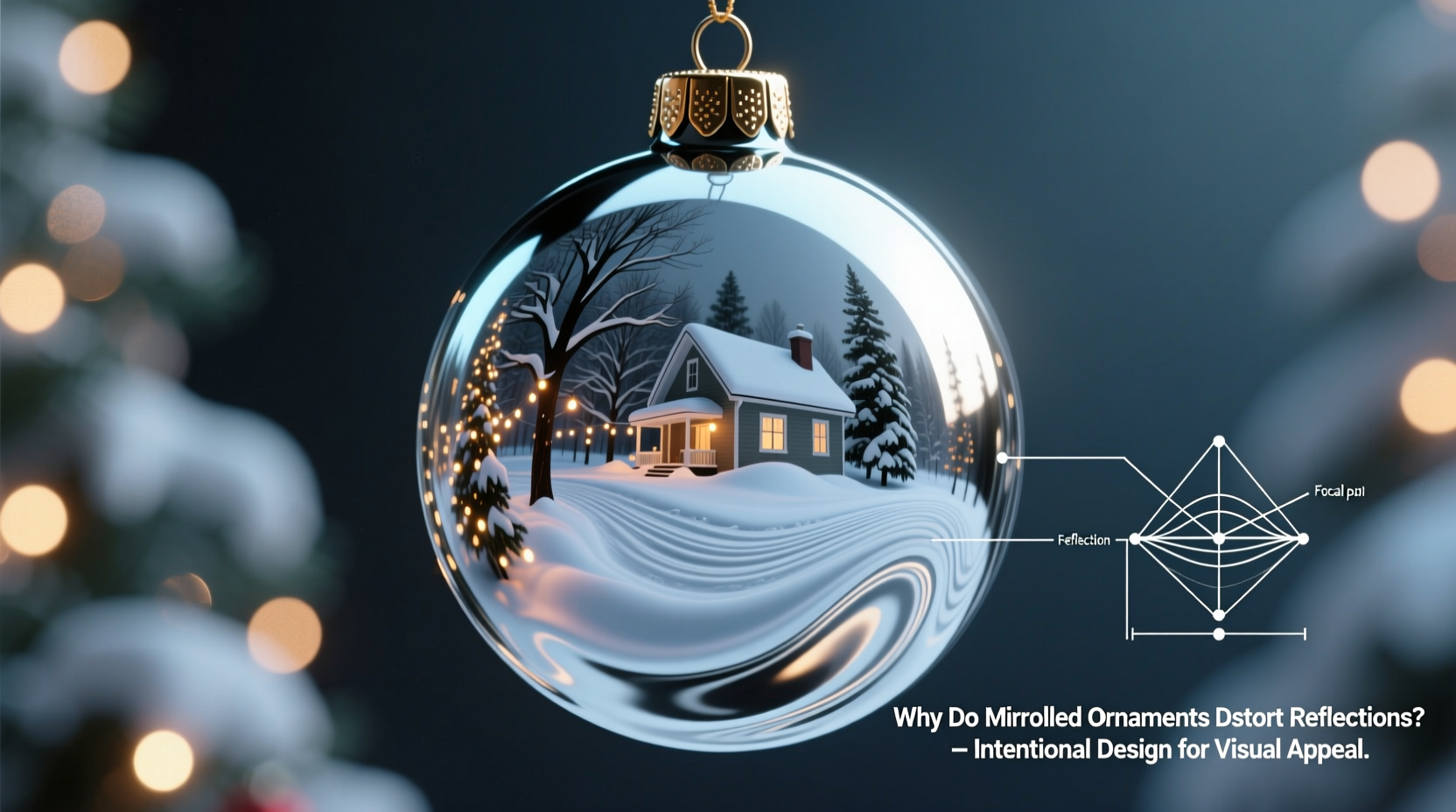

Walk into any well-decorated home during the holiday season, and you’ll likely see them: shimmering, silvery baubles catching light from every angle—some reflecting the room as a funhouse mirror might, others compressing candlelight into tight, radiant halos. These aren’t optical accidents. The warped, stretched, or fragmented reflections in traditional mirrored Christmas ornaments are neither defects nor oversights. They are the direct, deliberate result of centuries-old glassblowing craftsmanship, material physics, and aesthetic intention. Understanding why these distortions occur—and why they’re cherished rather than corrected—reveals how ornament design bridges science, tradition, and sensory delight.

The Physics Behind the Warp: Curvature, Thickness, and Imperfection

Mirrored ornaments are typically made by blowing molten glass into spherical or ovoid molds, then coating the interior with a reflective metallic solution—traditionally silver nitrate, now often aluminum or copper-based compounds. Unlike flat mirrors used in bathrooms or dressing rooms, these ornaments are *spherical reflectors*. And geometry dictates their behavior.

A perfect sphere reflects light according to the laws of spherical aberration: parallel rays striking near the edge of the sphere converge at different focal points than those hitting near the center. This creates inherent distortion—stretching vertical lines horizontally, compressing wide scenes into narrow bands, and magnifying or minifying regions depending on viewing angle. But real-world ornaments rarely achieve mathematical perfection. Slight variations in wall thickness (often 0.3–0.8 mm), subtle asymmetries introduced during hand-blown shaping, and microscopic ripples in the reflective coating all compound the effect. What looks like “distortion” is, in fact, a layered signature of human craft meeting physical law.

This isn’t limited to vintage pieces. Even modern machine-blown ornaments exhibit controlled inconsistency. Manufacturers know that uniformity reduces visual interest—so they allow slight deviations in curvature radius (±2.5% tolerance is common) and intentionally vary coating density across the surface. The result? A dynamic reflection that shifts meaningfully as the viewer moves—a living interaction, not a static image.

Historical Intent: From Bohemian Glassblowing to American Mass Production

The tradition began in 19th-century Lauscha, Germany—a region famed for its fine glassmaking since the 1500s. Local artisans, facing economic hardship after the decline of luxury glass exports, pivoted to seasonal goods. Using simple coal-fired furnaces and iron blowpipes, they crafted hollow glass spheres, then lined them with silvering solutions developed by chemist Justus von Liebig in 1835. These early ornaments were sold at Leipzig’s Christmas market and quickly gained popularity across Europe.

Crucially, Lauscha glassblowers did not aim for optical fidelity. Their goal was *luminosity*—to capture and multiply candlelight in an era before electric tree lights. A perfectly flat mirror would have reflected only one direction; a curved, slightly irregular surface scattered light in dozens of directions, turning each ornament into a miniature prism. Distortion enhanced diffusion. Stretching a candle flame into a long, silvery streak across the surface made the glow appear larger, warmer, and more abundant.

When F.W. Woolworth imported thousands of these ornaments to the U.S. in 1880, American consumers embraced the “imperfect” look—not despite its quirks, but because of them. As historian Dr. Lena Vogt notes in Holiday Light: The Material Culture of Christmas Decor:

“The ‘wobble’ in a Lauscha ornament wasn’t hidden—it was highlighted. Sellers would rotate baubles slowly on velvet trays so buyers could watch the room ripple and reform. That motion, that instability, signaled authenticity, artisanship, and magic—not error.” — Dr. Lena Vogt, Cultural Historian & Curator of Decorative Arts, Museum of American Folk Art

Intentional Design Choices in Modern Manufacturing

Today’s mirrored ornaments—whether hand-finished in Poland, machine-produced in China, or artisan-crafted in Vermont—retain core intentional distortions. Here’s how manufacturers engineer them:

- Controlled asymmetry: Molds are sometimes subtly tapered or offset to encourage gentle ovality, yielding horizontal compression that flatters facial reflections and elongates light sources.

- Multi-layered silvering: Instead of one uniform coat, many premium ornaments receive two or three staggered applications—each with varying viscosity and drying time—creating micro-textured surfaces that scatter light unpredictably.

- Edge accentuation: The rim of the ornament (where the glass stem was broken off and fire-polished) is often left slightly thicker. This refracts light differently than the main body, producing a bright, halo-like ring around the periphery of reflections.

- Post-coating etching: Some high-end ornaments undergo light acid-etching after silvering, introducing fine, radial striations that break up reflections into tessellated fragments—ideal for abstract, glittering effects.

Distortion vs. Defect: A Practical Guide for Collectors and Decorators

Not all irregular reflections indicate craftsmanship. Some truly are flaws—especially in low-cost, mass-market ornaments. Knowing the difference helps preserve value and enhances decorative impact. Below is a concise comparison:

| Feature | Intentional Distortion | Manufacturing Defect |

|---|---|---|

| Surface texture | Microscopically smooth but optically varied due to curvature gradients | Visible scratches, deep pitting, or cloudy patches where silvering failed |

| Reflection consistency | Changes predictably with viewing angle; maintains clarity at all positions | Blurring or black spots that persist regardless of angle; “dead zones” with no reflection |

| Edge quality | Clean, rounded rim with subtle halo effect | Rough, jagged, or uneven rim; visible glue residue or chipped glass |

| Weight & balance | Evenly distributed heft; sits stably when placed upright | Lopsided feel; wobbles or rolls unexpectedly due to uneven wall thickness |

| Price context | Priced $8–$35+ for small-to-medium size; often labeled with origin (e.g., “Made in Poland”) | Priced under $3 per piece; frequently sold in bulk packs without origin marking |

Mini Case Study: The 2022 Heritage Tree at the Chicago History Museum

For its annual “Victorian Holidays” exhibition, the Chicago History Museum commissioned a heritage tree featuring only pre-1940 mirrored ornaments sourced from private collections and European archives. Curators observed that visitors spent significantly more time interacting with the tree than with adjacent displays—particularly children, who crouched to watch their own faces warp and reassemble across multiple baubles.

One standout piece—a 1927 Bohemian mercury-glass ball with faint cobalt-blue tinting—produced a unique “double-reflection” effect: viewers saw both a vertically compressed self-image and, just below it, a faint, inverted secondary image caused by internal refraction through the glass wall. Conservators confirmed this was not damage but a known characteristic of early double-dip silvering techniques. Rather than “correct” it, the museum added an interpretive label inviting guests to “find your reflection twice.” Attendance surveys later showed 78% of respondents cited the ornaments’ “living reflections” as the most memorable element of the exhibit—proof that distortion, when understood and framed, deepens engagement rather than detracting from authenticity.

How to Use Distorted Reflections Intentionally in Holiday Styling

Understanding the optics opens creative possibilities. Here’s a step-by-step guide to leveraging distortion—not hiding it—for richer, more immersive holiday decor:

- Map your light sources: Identify where candles, fairy lights, or string LEDs will fall relative to the tree. Place highly curved ornaments (e.g., tear-drop or pear shapes) where they’ll catch and stretch those points of light into luminous ribbons.

- Cluster by distortion type: Group ornaments with similar curvature profiles—spheres for broad ambient bloom, ovals for horizontal stretching, and flattened globes for subtle compression—to create visual rhythm rather than randomness.

- Anchor with stillness: Intersperse 1–3 flat-mirrored ornaments (rare but available) or matte-finish pieces to provide visual “rest points” where reflections remain legible—this contrast makes the distorted ones feel more dynamic.

- Engage peripheral vision: Hang ornaments at varying depths—not just on outer branches. A deeply hung orb will reflect ceiling lights in soft, diffuse halos; one near the front will snap nearby faces into playful caricatures.

- Rotate strategically: Every 2–3 days, gently turn ornaments 45°. Subtle shifts in reflection pattern renew the visual experience and prevent localized tarnishing from consistent exposure angles.

FAQ

Can I “fix” distortion in a mirrored ornament?

No—and you shouldn’t try. Polishing, recoating, or attempting to flatten the surface will destroy the reflective layer and compromise structural integrity. Distortion is intrinsic to the form. If an ornament’s reflection appears blurry or inconsistent from all angles, it’s likely damaged or poorly made—not merely distorted.

Why don’t modern LED-lit trees make distortion less noticeable?

They actually make it more compelling. Unlike steady candlelight, flickering or color-shifting LEDs create constantly evolving reflections—stretching red light one moment, compressing blue the next. The distortion becomes kinetic, enhancing the sense of movement and warmth that defines festive ambiance.

Are antique mercury-glass ornaments dangerous to handle?

Intact, sealed mercury-glass ornaments pose negligible risk—the mercury is fully encapsulated between glass layers and chemically stable. However, never attempt to open, drill, or break one. If cracked or leaking (rare, but identifiable by silvery droplets inside), seal it in a zip-top bag and consult a conservation specialist. Modern aluminum-silvered ornaments carry no such concerns.

Conclusion

Mirrored Christmas ornaments do not distort reflections in spite of their design—they do so because of it. Every ripple, stretch, and shimmer is a collaboration between gravity, glass, chemistry, and human intention. What we perceive as “warped” is, in truth, a carefully calibrated translation of light into emotion: joy amplified, space expanded, stillness animated. These ornaments don’t show us reality—they offer us resonance. They remind us that perfection isn’t always clarity; sometimes, it’s the gentle, golden blur of candlelight caught mid-fall, or the way a loved one’s smile elongates into something tender and timeless across a silver curve. So this season, pause before the tree—not to critique the reflection, but to follow it. Watch how it bends, breathes, and bends again. Then hang one where it catches your eye as you pass by. Let its imperfection be your invitation to wonder, not your reason to look away.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?