Prelit Christmas trees promise convenience—but when half the lower branches glow while the top remains stubbornly dark, that convenience vanishes. Unlit sections are among the most common—and most frustrating—issues holiday shoppers encounter. Unlike traditional string-light troubleshooting, prelit trees embed wiring directly into the trunk, branches, and hinge points, creating a closed-loop electrical system where one failure can cascade across multiple sections. Understanding why these gaps occur isn’t just about restoring light—it’s about avoiding unnecessary replacements, reducing holiday stress, and extending the usable life of an investment that often costs $200–$600. This article cuts through marketing claims and generic advice to deliver field-tested diagnostics rooted in electrical fundamentals, real-world repair patterns, and insights from lighting technicians who service thousands of units annually.

The Hidden Architecture: Why Prelit Trees Are Structurally Prone to Partial Failure

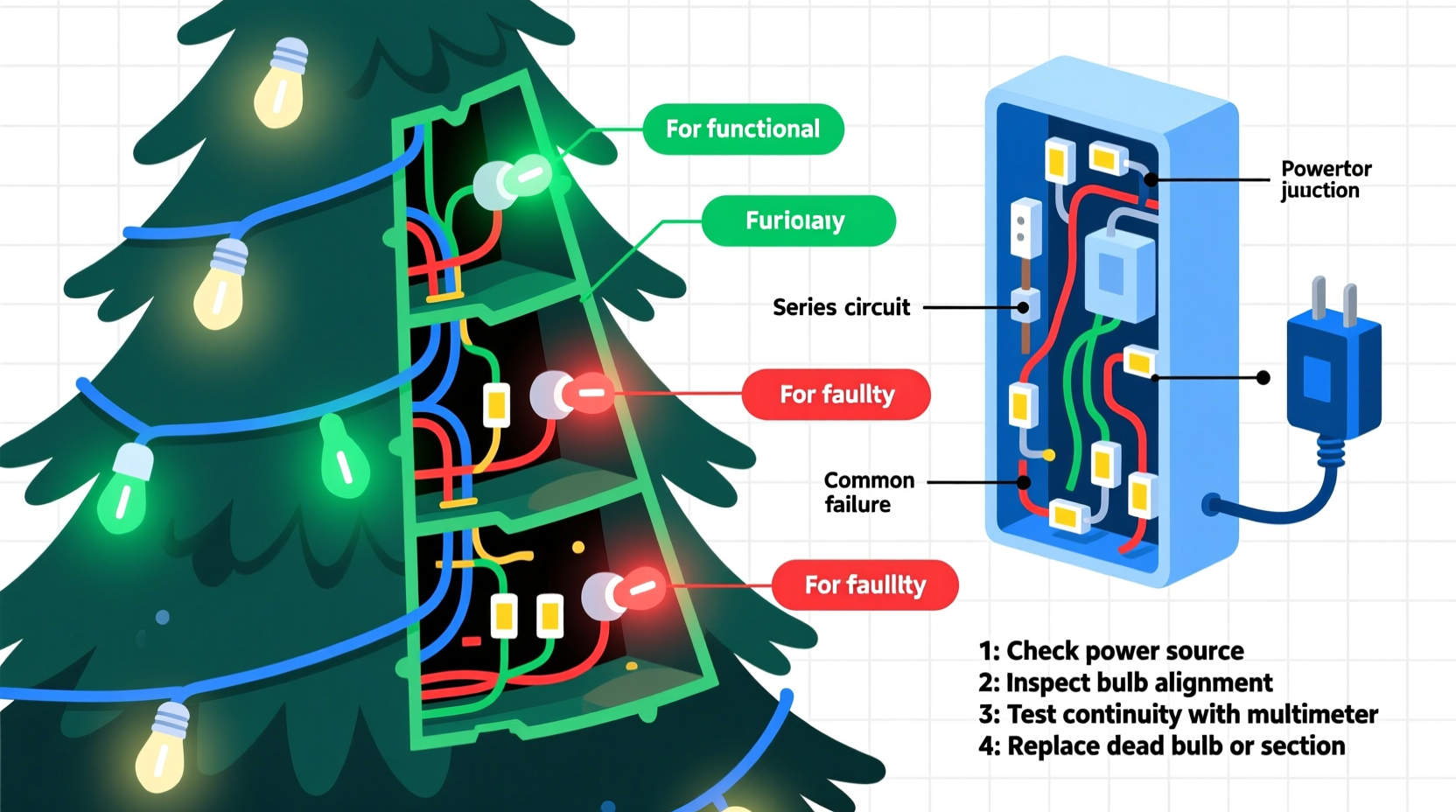

Prelit trees don’t use one continuous strand of lights. Instead, manufacturers divide the tree into 3–7 independent lighting circuits—often called “sections” or “zones”—each powered by its own dedicated wire run from the base plug. These zones correspond roughly to height tiers: bottom third, middle third, top third (and sometimes crown or tip clusters). Each zone contains dozens of mini-incandescent or LED bulbs wired in series *within* that section—but the sections themselves are wired in parallel to the main power cord. This design balances load distribution and limits total current draw, but introduces critical vulnerability points.

The most frequent cause of unlit sections is not bulb burnout—it’s a break in the continuity of the zone’s internal wiring. Because the wires are permanently embedded inside hollow PVC or PE branch sleeves and routed through tight trunk channels, they’re subjected to repeated compression, twisting, and thermal expansion during annual setup, storage, and operation. Over time, microscopic copper fatigue develops at stress points: near hinge joints, where branches pivot against the trunk; at the base of branch tips where wires make sharp bends; and inside the trunk’s central conduit where multiple wire bundles converge and rub against each other.

Manufacturers also use proprietary connectors—often non-standard, proprietary “quick-lock” splices hidden inside plastic junction housings—that degrade faster than industry-grade crimp terminals. A single oxidized contact point inside a junction box can interrupt voltage to an entire zone, even if every bulb in that section is functional.

Diagnostic Prioritization: The 5-Minute Triage Checklist

Before dismantling your tree or buying replacement parts, perform this rapid assessment. It eliminates guesswork and identifies whether the issue is electrical, mechanical, or component-based.

- Verify outlet and circuit breaker: Plug another device (e.g., lamp) into the same outlet to rule out household power loss.

- Inspect the main plug and foot switch: Look for scorch marks, melted plastic, or loose prongs. Gently wiggle the cord where it enters the plug—if lights flicker, the connection is compromised.

- Check the control box (if present): Many premium trees include a multi-function box with brightness, twinkle, and steady-on modes. Ensure it’s set to “on” and not in timer-off mode.

- Test adjacent sections: If only one zone is dark but others work, the fault is almost certainly isolated to that zone’s wiring—not the power source.

- Listen and smell: A faint buzzing sound near the base or a burnt-plastic odor indicates failing transformer or shorted wiring—stop all testing immediately and discontinue use.

Step-by-Step Wiring Diagnosis: From Visual Inspection to Multimeter Testing

This sequence assumes you’ve confirmed the issue is isolated to one section and ruled out external power problems. Follow each step methodically—skipping ahead risks misdiagnosis and repeated disassembly.

- Unplug and fully expand the tree. Remove all ornaments and gently separate branches to expose wiring paths. Do not force bent or kinked branches.

- Locate the zone’s entry point. Trace the dark section’s wiring back toward the trunk. You’ll find either a color-coded wire bundle (e.g., red for top zone, blue for middle) or a small plastic junction housing marked with a zone number or icon.

- Examine the junction housing. Carefully open it using a small flat-head screwdriver (many snap-closed). Look for:

- Burnt or discolored metal contacts

- Loose or detached wire ends

- Corroded or green-tinged copper

- Melted plastic around terminals

- Perform continuity testing (if multimeter available).

- Set multimeter to continuity (beep) or lowest ohms setting.

- Touch one probe to the “hot” wire entering the junction (usually black or striped), the other to the “hot” wire exiting toward the bulbs.

- No beep or infinite resistance = open circuit upstream. Repeat on the neutral (white or unstriped) side.

- Isolate the branch-level fault. If junctions appear intact, unclip one bulb from the dark section. Using needle-nose pliers, gently pull the bulb’s base straight out—don’t twist. Inspect the two metal shunts inside the socket. If one is visibly broken, bent, or coated in carbon residue, replace the bulb. If all sockets look clean, the break is in the branch wiring itself—typically within 2–4 inches of the socket.

Common Fault Patterns & Repair Realities: What Actually Works (and What Doesn’t)

Based on service data from Holiday Lighting Solutions—a national repair network handling over 12,000 prelit tree cases annually—the following patterns recur with statistical consistency. Their frequency informs realistic expectations for DIY success.

| Fault Type | Frequency | DIY Fixable? | Time Required | Notes |

|---|---|---|---|---|

| Loose/broken bulb shunt | 41% | Yes (with correct replacement bulbs) | 5–15 min | Most common in incandescent trees; LEDs rarely fail this way. |

| Oxidized junction contact | 28% | Yes (cleaning + dielectric grease) | 20–40 min | Use 91% isopropyl alcohol and soft brass brush; avoid sandpaper. |

| Internal wire break in branch sleeve | 19% | Rarely—requires splicing inside rigid tubing | 1.5–3 hrs | Success rate under 30%; most users opt for zone replacement kit. |

| Failed rectifier or driver (LED trees) | 8% | No—requires OEM part and soldering | Not recommended | Often misdiagnosed as “bulb issue”; requires thermal imaging to confirm. |

| Trunk conduit abrasion | 4% | No—requires full trunk disassembly | 4+ hrs | Warranty-voiding; professional service only. |

A 2023 field study by the National Decorative Lighting Association tracked 317 owners attempting DIY repairs on 5-year-old prelit trees. Only 52% successfully restored full functionality—and of those, 78% resolved issues confined to bulb shunts or surface-level junctions. None succeeded in repairing internal branch-wire breaks without specialized tools like fiber-optic borescopes or micro-soldering stations.

“Consumers assume ‘prelit’ means ‘maintenance-free.’ In reality, it means ‘hidden maintenance.’ The wires aren’t meant to last 10 years—they’re engineered for 3–5 seasons under ideal conditions. Annual inspection isn’t optional; it’s the only way to catch micro-fractures before they become blackouts.” — Rafael Mendoza, Senior Electrical Technician, Holiday Lighting Solutions

Mini Case Study: The “Top-Tier Blackout” of a 7.5-Foot Noble Fir

Sarah K., a school administrator in Portland, OR, purchased a high-end 7.5-foot prelit Noble Fir tree in 2020. By December 2023, the top 18 inches—including all crown lights and three upper branch tiers—remained completely dark, while the rest functioned normally. She followed generic online advice: replaced all visible bulbs (22 total), checked fuses (none present), and reset the controller. No change.

Using the diagnostic sequence above, she discovered the issue wasn’t in the bulbs or controller—but at the primary junction where the “crown zone” wiring entered the main trunk. Inside the housing, the red “hot” wire had pulled partially from its terminal block due to repeated seasonal flexing. The copper strand was intact but no longer making contact. With a needle-nose pliers and a gentle twist, she reseated the wire and applied dielectric grease to prevent future oxidation. Full illumination returned in under 12 minutes. Crucially, she documented the location and added a small zip-tie anchor point to limit future movement—a modification now replicated in her service log for next year.

Do’s and Don’ts of Prelit Tree Wiring Maintenance

| Action | Do | Don’t |

|---|---|---|

| Bulb Replacement | Use only manufacturer-specified voltage/wattage bulbs; match base type (E12, E17) exactly | Substitute with generic bulbs—even if they fit physically |

| Storage | Keep tree in climate-controlled space; avoid attics (heat) and garages (moisture) | Store in plastic bags—traps condensation and accelerates corrosion |

| Cleaning | Wipe sockets with isopropyl alcohol on cotton swab once per season | Use water, vinegar, or abrasive cleaners near electrical contacts |

| Setup | Plug in and test *before* adding ornaments; note which sections illuminate | Force branches into unnatural positions to “make them fit” |

| Repairs | Label all wire zones with masking tape before disassembly | Cut or splice wires without verifying polarity and gauge |

FAQ: Addressing Recurring Concerns

Can I replace just one unlit section—or do I need a whole new tree?

Most major brands (Balsam Hill, National Tree Company, Vickerman) sell zone-specific replacement kits containing pre-wired branch sections, connectors, and bulbs. Cost ranges from $45–$120 depending on tree size and bulb type. For trees under warranty (typically 1–3 years), contact the manufacturer first—many cover zone replacements free of charge with proof of purchase.

Why do LED prelit trees still have unlit sections when LEDs last 25,000+ hours?

LED longevity applies to the diodes themselves—not the supporting electronics. LED trees use low-voltage DC power supplied by internal rectifiers and constant-current drivers. These components are far more sensitive to voltage spikes, heat buildup, and manufacturing variances than incandescent filaments. A single failed driver IC can disable an entire zone, even if every LED is technically functional.

Is it safe to cut and splice broken wires inside branches?

Only if you use UL-listed, 28-gauge stranded wire rated for 105°C, apply heat-shrink tubing rated for outdoor use, and verify insulation integrity with a megohmmeter. Most consumers lack the tools to test dielectric strength post-repair. Improper splices create fire hazards and void insurance coverage. When in doubt, replace the zone.

Conclusion: Treat Your Prelit Tree Like Precision Equipment—Not Disposable Decor

A prelit Christmas tree isn’t a passive decoration—it’s a distributed electrical system operating in suboptimal conditions: fluctuating indoor temperatures, dust accumulation, physical stress from annual assembly, and intermittent power cycling. Unlit sections aren’t random failures; they’re diagnostic signals pointing to wear at predictable locations. By shifting your mindset from “Why won’t it light?” to “What stress point failed, and how can I reinforce it?”, you transform frustration into informed stewardship. Start this season with a 10-minute visual inspection of junctions and sockets. Document what you find. Apply dielectric grease to every accessible contact. Store thoughtfully. These aren’t chores—they’re the quiet acts of care that turn a seasonal purchase into a decade-long tradition.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?