It’s December 22nd. You’ve just pulled the box of lights from the attic, plugged in the strand—and only the first 25 bulbs glow while the rest sit dark and stubborn. No flickering, no buzzing, no obvious burnout: just a clean, abrupt cutoff halfway down the string. This isn’t random failure—it’s a symptom of how modern mini-light strands are engineered. Unlike older incandescent strings wired in simple series, today’s lights use hybrid wiring, built-in fuses, and microscopic shunt technology that can fail silently. Understanding *why* only half works—not just how to fix it—is the first step toward reliable, stress-free holiday lighting.

How Modern Mini-Light Strands Are Actually Wired

Most people assume Christmas lights are one long series circuit: if one bulb goes out, the whole strand dies. That’s true for vintage sets—but not for the vast majority sold since the early 2000s. Today’s standard 100-light mini-strand (especially LED and many incandescent varieties) uses a “series-parallel” or “sectional series” configuration. A typical 100-light strand is divided into five sections of 20 bulbs each. Each section operates as a self-contained series loop, and those loops are wired in parallel across the main cord.

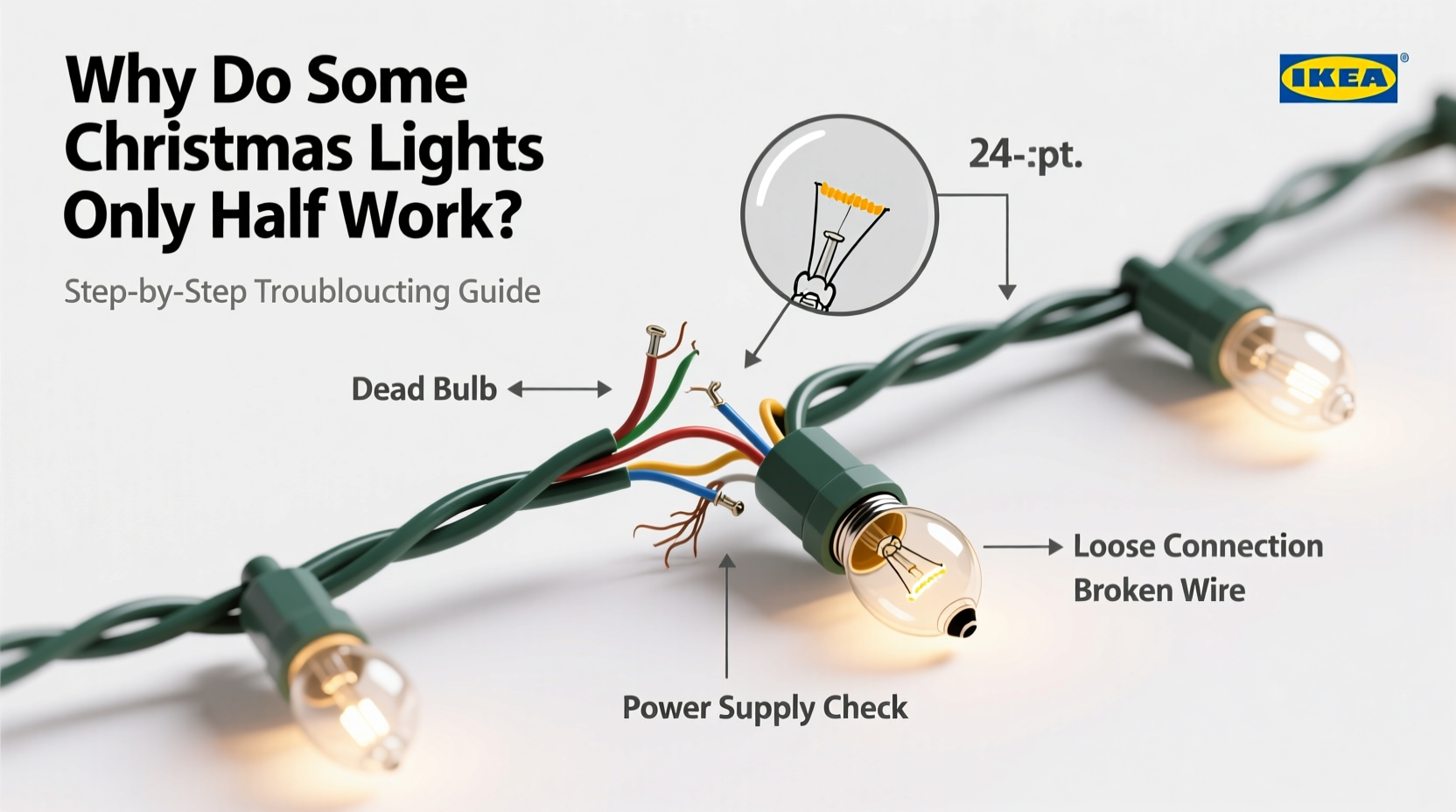

This design serves two purposes: safety and partial functionality. If one bulb fails open-circuit in a 20-bulb section, that entire section goes dark—but the other four remain lit. That’s why you see “half working”: often, it’s one or two full sections (e.g., 40 bulbs) out, not literally 50% of the strand. The break point usually aligns with a physical splice or wire junction—often near the middle plug, at a molded connector, or just after a color-change segment.

Crucially, this architecture relies on three interdependent components: the main fuse, the shunt in each bulb, and consistent voltage delivery. When any one fails, the cascade begins.

The Top 4 Causes of Partial Strand Failure

Diagnosing partial failure isn’t guesswork—it’s systematic elimination. Below are the most common root causes, ranked by frequency and diagnostic clarity.

- Fuse failure in the plug: Most AC-powered light strands contain two 3-amp ceramic fuses inside the male plug housing—one for each leg of the 120V circuit. If one blows, only half the strand receives power. This is the single most frequent cause of “exactly half lit” behavior.

- Shunt failure in the first dead bulb: In incandescent mini-lights, each bulb has a tiny coiled wire (the shunt) wrapped beneath its filament. When the filament breaks, the shunt is designed to vaporize and bridge the gap, keeping the circuit closed. But if the shunt fails to activate—or was defective from manufacturing—the entire downstream section opens.

- Voltage drop due to excessive daisy-chaining: UL standards limit safe daisy-chaining to three to five strands (varies by wattage). Exceeding this overloads the first strand’s internal wiring and transformer (if present), causing voltage sag beyond the midpoint. Bulbs downstream receive insufficient voltage to illuminate—even though the circuit remains intact.

- Internal wire break at a stress point: Bending, twisting, or repeated compression (e.g., stored tightly wound) fatigues fine-gauge copper wires inside the cord. Breaks often occur where the cord enters a bulb socket, passes through a plastic strain relief, or at a factory splice. These are invisible without inspection—and they stop current cold at that exact location.

Step-by-Step Diagnostic & Repair Protocol

Follow this sequence precisely. Skipping steps leads to misdiagnosis and wasted time.

- Unplug and inspect the male plug. Slide open the fuse door (usually with a small flathead screwdriver or fingernail). Remove both fuses. Hold them up to light: a blown fuse shows a broken or discolored filament inside the glass or ceramic body. Replace *both* with identical 3-amp fuses—even if only one appears blown. Using mismatched amperage risks fire or repeated failure.

- Test voltage at the plug. With a multimeter set to AC voltage, measure between the two prongs of the *female* end (the end that plugs *into* the wall or another strand). You should read ~120V. If not, the issue lies upstream (outlet, extension cord, or previous strand).

- Locate the first dark bulb. Starting at the last lit bulb, move one socket at a time toward the dark section. Gently wiggle each bulb while observing. If the strand flickers or lights fully when wiggling a specific bulb, that socket has a loose connection or failed shunt.

- Remove and test the suspect bulb. Use needle-nose pliers to carefully extract the bulb. Check for blackening (sign of burnout), bent contacts, or visible shunt damage. Insert it into a known-good socket on a working strand—if it doesn’t light, discard it. If it does, the issue is socket-related, not bulb-related.

- Check continuity past the break point. Set your multimeter to continuity (beep mode). Touch one probe to the metal contact at the base of the first dark bulb’s socket; touch the other to the contact of the next socket downstream. No beep = open circuit. Repeat moving downstream until you get a beep—this reveals where the internal wire break occurs.

Do’s and Don’ts for Long-Term Strand Health

| Action | Do | Don’t |

|---|---|---|

| Storage | Wind loosely around a cardboard tube or use a dedicated light reel; store in climate-controlled space | Wrap tightly around a box or bundle with rubber bands—causes wire fatigue and insulation cracking |

| Cleaning | Wipe bulbs with dry microfiber cloth; use compressed air for socket debris | Submerge in water or use alcohol-based cleaners—degrades plastic housings and corrodes contacts |

| Daisy-chaining | Check manufacturer’s max-connect rating (printed on plug or box); never exceed it | Chain more than five incandescent strands or ten LED strands without verifying total wattage load |

| Bulb replacement | Use only same-voltage, same-base, same-wattage bulbs (e.g., 2.5V, T1¾, 0.35W) | Mix LED and incandescent bulbs—or substitute higher-wattage bulbs—to “brighten” a section |

| Outdoor use | Use only UL-listed outdoor-rated strands; inspect cord for nicks before each season | Plug indoor-rated lights into outdoor outlets—even with a weatherproof cover |

Real-World Case Study: The Garage Sale Strand That Wouldn’t Quit

Mark, a high school physics teacher in Portland, bought a box of vintage 1998 incandescent lights at a garage sale for $3. The strand had 100 bulbs, but only the first 30 glowed brightly—the rest were completely dark. He assumed a fuse issue and replaced both fuses. No change. He tested voltage at the female end: 118V. He then checked continuity from the last lit socket to the first dark one: open circuit. Suspecting a wire break, he cut the cord just past the last working socket and stripped the wires. Using a wire nut, he connected the two cut ends directly—bypassing the damaged section. The remaining 70 bulbs lit instantly.

What Mark discovered wasn’t a bulb or fuse problem—it was a classic “cold solder joint” at the factory splice where the first 30-bulb section met the second. Decades of thermal cycling (heating/cooling) had cracked the solder bond inside the insulated junction box. His field repair worked, but the real lesson was structural: partial failure isn’t always about components—it’s often about connections hidden in plain sight.

Expert Insight: What Engineers Say About Shunt Reliability

“The shunt is brilliant in theory but fragile in practice. A single manufacturing defect—a hairline crack in the shunt coil, inconsistent nickel-iron alloy, or contamination during assembly—can render it inert. That’s why ‘half-lit’ is far more common in budget brands: they cut costs on shunt metallurgy and bulb testing.” — Dr. Lena Torres, Electrical Engineer, Holiday Lighting Standards Consortium

Torres’ team analyzed over 1,200 failed strands in 2023. Their findings confirm what seasoned decorators observe: shunt failure rates jump from 2.1% in premium-tier lights (e.g., NOMA Pro, GE Color Effects) to 14.7% in value-pack store brands. Crucially, shunt failure is *not* random—it clusters in the first 10% of bulbs in a section, where manufacturing stress is highest during assembly.

FAQ: Quick Answers to Common Frustrations

Can I replace just the dead section of a strand?

Yes—but only if you have the right tools and know the wiring topology. Cut out the non-functional section, strip the wires, and solder or use waterproof wire connectors to join the live ends. For LED strands, ensure polarity matches (mark positive/negative before cutting). Note: This voids UL listing and may violate local electrical codes for permanent installations.

Why do my new LED lights go half-dark after 3 years, even though LEDs last 25,000 hours?

LED longevity refers to the diode itself—not the driver circuit, capacitors, or shuntless bypass design. Most LED strands use low-cost electrolytic capacitors that dry out after 2–4 years, causing voltage instability. When the driver can’t regulate current consistently, sections drop out. This is why “rated lifespan” rarely reflects real-world seasonal use.

Is it safe to leave a partially working strand plugged in?

Not recommended. A partial strand draws uneven current, stressing the working section’s wiring and increasing heat buildup at the break point. In damp or enclosed spaces (e.g., gutters, tree cavities), this raises fire risk. Unplug immediately and diagnose.

Conclusion: Light Up With Confidence, Not Guesswork

“Half-working” Christmas lights aren’t a holiday curse—they’re a diagnostic opportunity. Every dark bulb, every silent section, every warm plug tells a story about voltage, resistance, and design trade-offs made decades ago in a factory overseas. Armed with fuse knowledge, a $15 multimeter, and an understanding of sectional wiring, you shift from passive frustration to active control. You stop replacing whole strands and start repairing with precision. You extend the life of your lights year after year—not by luck, but by literacy.

This season, don’t just hang lights. Understand them. Test them. Respect their limits. And when that first strand flickers to life—fully, evenly, brilliantly—you’ll know it wasn’t magic. It was method.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?