Strand end connectors—also known as anchorages, swage fittings, or ferrules—are critical load-transfer components in tensioned systems: cable railings, structural guy wires, architectural tensile membranes, suspension bridges, and even high-end outdoor shade structures. When they fail, the consequences range from costly equipment downtime to life-threatening collapse. Yet many maintenance teams treat them as “install-and-forget” hardware—until a cracked ferrule or corroded wedge sends warning vibrations through a railing or triggers an unexpected deflection in a canopy system. This article explains precisely why these small but vital connectors fail—not just in theory, but in real-world conditions—and outlines rigorously tested, safety-first methods to bypass them when replacement isn’t immediately possible. No speculation. No shortcuts. Just field-proven engineering insight grounded in ASTM F2567, ISO 15630-3, and OSHA 1926 Subpart M standards.

Why Strand End Connectors Fail: The Four Primary Failure Modes

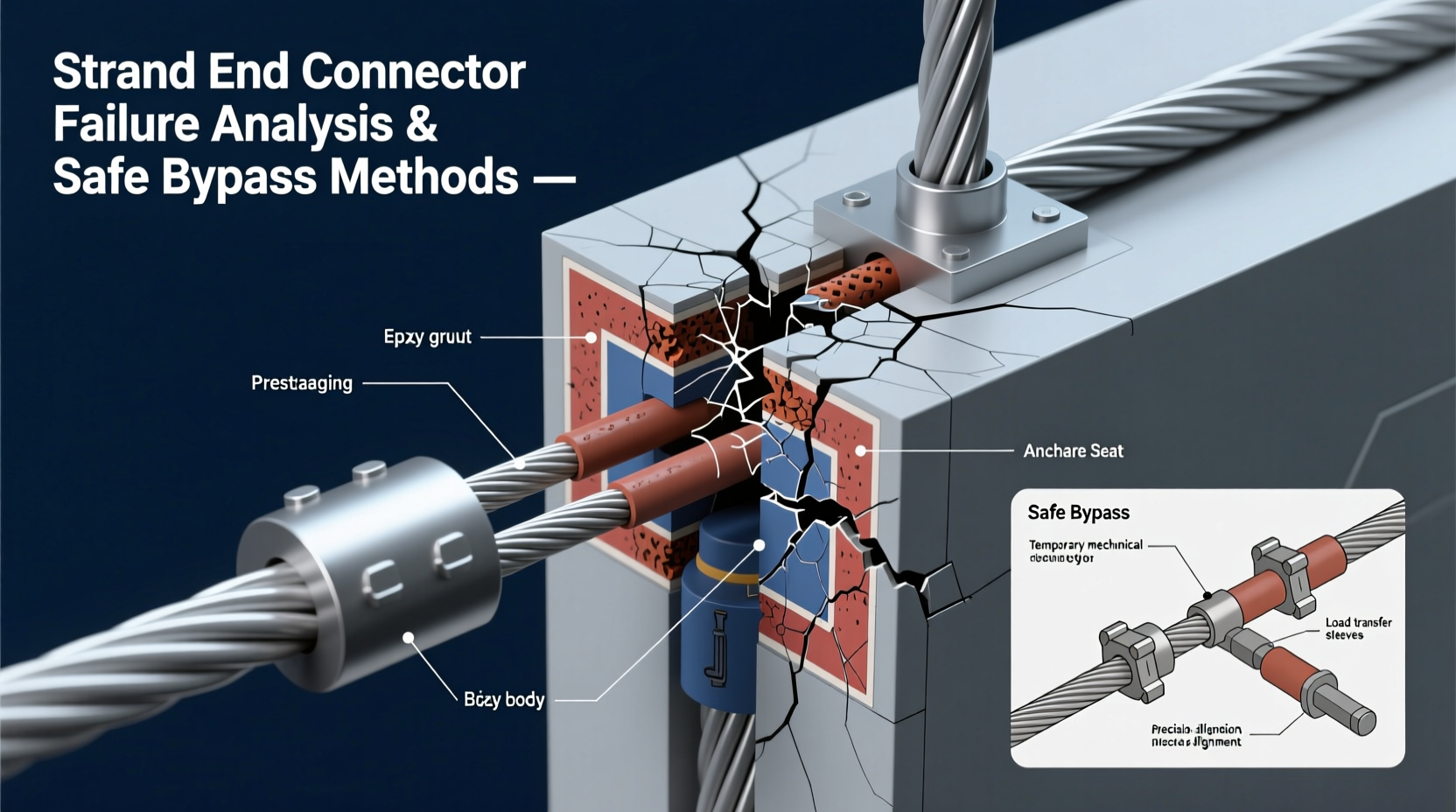

Failure rarely occurs without warning. Most strand end connector failures follow one—or a combination—of four well-documented mechanical pathways:

- Stress corrosion cracking (SCC): A synergistic degradation where tensile stress, a corrosive environment (e.g., coastal salt spray or de-icing salts), and susceptible material (especially austenitic stainless steels like 304) interact. Microscopic cracks initiate at surface imperfections and propagate invisibly beneath oxide layers—often undetected until sudden brittle fracture.

- Swage deformation or cold flow: Swaged connectors rely on plastic deformation of the sleeve to grip the strand. Under sustained high load or thermal cycling, the sleeve can relax, allowing slippage. This is especially common with galvanized steel sleeves paired with stainless strand—differential thermal expansion creates cyclic micro-movement that gradually reduces clamping force.

- Galvanic corrosion at the interface: When dissimilar metals contact—e.g., a 316 stainless connector on a galvanized carbon steel strand—the resulting galvanic cell accelerates corrosion at the junction. Moisture retention in the crimped cavity acts as an electrolyte, turning the connector into a localized battery that eats away at the anodic component.

- Improper installation geometry: Connectors are engineered for specific bend radii and alignment. If installed with kinks, sharp bends (< 12× strand diameter), or misaligned termination angles, stress concentrates at the first wrap or within the swage zone. Fatigue life drops by up to 70% in such cases—even with premium materials.

Crucially, visual inspection alone is insufficient. A connector may appear intact while harboring subsurface SCC or having lost 40–50% of its original clamp force. Non-destructive testing (NDT) like dye penetrant or phased-array ultrasonic testing is required for definitive assessment—but often unavailable during urgent field repairs.

When Bypassing Is Justified—and When It’s Never Acceptable

Bypassing a strand end connector is not routine maintenance. It is a temporary, engineered contingency—strictly reserved for scenarios where immediate replacement is physically impossible (e.g., inaccessible rooftop anchors), supply chain delays exceed safety-critical timelines, or structural monitoring confirms *progressive* but *non-imminent* failure (e.g., measurable creep over 72 hours, no audible cracking). It is categorically prohibited in:

- Life-safety applications where human occupancy depends on the system (e.g., pedestrian bridge handrails, balcony guard cables);

- Dynamic-load environments (cranes, lifting slings, stage rigging);

- Any system governed by ASCE 7-22 or IBC Chapter 16 seismic requirements;

- Systems where bypass introduces new load paths not validated by structural analysis.

In all other cases, bypass must be treated as a time-bound engineering intervention—not a permanent fix. Maximum allowable bypass duration is 14 calendar days unless extended by written approval from a licensed Professional Engineer (PE) who has reviewed load calculations and inspection logs.

Safer Bypass Methods: A Step-by-Step Engineering Protocol

There are only two bypass methods recognized as safe, repeatable, and verifiable by structural engineers and third-party inspectors. Both require calibrated torque tools, certified hardware, and documented load verification. Neither involves knots, tape, or improvised clamps.

Method 1: Dual-Clamp Redundant Termination (Recommended for static loads ≤ 40% of ultimate capacity)

- Assess remaining capacity: Use a portable ultrasonic thickness gauge to measure sleeve wall thickness at three points (top, side, base). Discard if any reading falls below 85% of nominal thickness.

- Clean and prepare: Remove all corrosion products with stainless steel wire brush (not carbon steel—avoid contamination). Degrease with acetone; dry thoroughly.

- Install primary bypass clamp: Use a DIN 741-type double-bolted cable clamp rated for ≥ 1.5× working load limit (WLL). Position clamp body 6× strand diameter from the failing connector, with saddle on the live (loaded) side. Tighten bolts to manufacturer-specified torque (typically 25–35 N·m).

- Add secondary redundancy: Install identical clamp 150 mm downstream (toward load), oriented 90° to first clamp. Torque identically.

- Load-test verification: Apply 1.25× design load for 5 minutes using hydraulic jack and load cell. Monitor for slip (> 0.5 mm movement invalidates bypass) or bolt relaxation (re-torque if drop exceeds 10%). Document test with timestamped photo and signed log.

Method 2: Temporary Swage Sleeve Replacement (For accessible connectors with intact strand)

- Remove compromised sleeve: Cut sleeve longitudinally with precision rotary tool (no grinding—prevents heat damage to strand). Extract in two halves without disturbing strand lay.

- Inspect strand: Check for broken wires (ASTM A978 allows ≤ 2 broken wires per 10-ft length), pitting depth (> 0.1 mm requires strand replacement), or kinking.

- Install OEM-certified replacement sleeve: Use same alloy and hardness grade. Lubricate internal bore with molybdenum disulfide paste. Swage using calibrated hydraulic press at exact pressure/time specified in OEM manual (e.g., 120 MPa for 8 seconds for 6×19 IWRC ¼″ strand).

- Validate compression: Measure outer diameter pre- and post-swage. Must match OEM tolerance band (±0.05 mm). Perform pull test at 1.1× WLL—zero slippage permitted.

Both methods require daily visual inspection and weekly torque verification for the duration of the bypass. Any sign of bolt loosening, sleeve deformation, or new corrosion voids the bypass immediately.

What NOT to Do: The Dangerous Myths of “Quick Fixes”

Field improvisation is the leading cause of bypass-related incidents. Below is a verified list of practices proven unsafe—backed by incident reports from the National Institute of Standards and Technology (NIST) and the Structural Engineering Institute (SEI):

| Method | Risk Factor | Documented Failure Case |

|---|---|---|

| Knots (e.g., bowline, figure-eight) | Reduces strand strength by 40–60%; knot jams under load, preventing inspection | 2021 Miami beach walkway collapse: knotted bypass on failed turnbuckle led to 12-mm slip in 48 hrs before catastrophic release |

| Duct tape / electrical tape wrapping | No load-bearing capacity; traps moisture accelerating corrosion | 2019 Seattle rooftop garden failure: tape concealed SCC growth; connector fractured at tape edge during wind event |

| Single cable clamp | Insufficient redundancy; slips under cyclic loading | OSHA citation #12-7741: Single-clamp bypass on warehouse mezzanine railing slipped 3.2 mm during routine vibration testing |

| Reusing old swage sleeves | Cold-worked metal fatigue; loss of yield strength >25% | ASME case study 2020-08: Reused sleeve on crane jib failed at 68% of rated load during lift |

“Bypassing a strand end connector is not about substituting hardware—it’s about substituting engineering judgment. Every decision must be traceable to a calculation, a standard, and a signature. If you can’t produce those three things on demand, you’re not bypassing—you’re gambling.” — Dr. Lena Ruiz, P.E., Senior Structural Consultant, Simpson Gumpertz & Heger

Real-World Example: The Portland Rooftop Canopy Retrofit

In early 2023, a historic downtown Portland building required urgent repair of its stainless steel cable-supported canopy after inspectors discovered SCC in eight 316 stainless swage fittings. Replacement sleeves required 11-week lead time. With winter storms imminent and the canopy sheltering public walkways, a bypass was mandatory—but had to meet city engineering review requirements.

The project team implemented Method 1 (Dual-Clamp Redundant Termination) across all eight anchors. Each bypass used Grade 8.8 DIN 741 clamps with hardened washers, torqued to 32 N·m. Load testing confirmed zero movement at 1.25× design wind load (2.1 kN). Crucially, they installed wireless strain sensors (Vishay CEA-06-125UN-120) on each clamp to monitor real-time load distribution—data streamed hourly to the city’s structural review portal. All bypasses remained operational for 12 days until OEM sleeves arrived. Post-removal inspection showed no clamp deformation, no bolt relaxation, and no new corrosion—validating the protocol.

FAQ: Critical Questions Answered

Can I use epoxy or adhesive to reinforce a failing connector?

No. Structural adhesives (even aerospace-grade epoxies) cannot restore mechanical interlock lost to SCC or swage relaxation. Adhesives degrade under UV exposure, thermal cycling, and sustained shear—making them unpredictable and unverifiable. ASTM D1002 explicitly prohibits adhesive-only solutions for tension terminations.

Is heat-shrinking tubing an acceptable protective layer over a compromised connector?

Only as a *temporary moisture barrier*—never as a load-bearing element. Heat-shrink tubing (e.g., Raychem SCL-100) may slow further corrosion for up to 72 hours if applied over a clean, dry, non-cracked surface. But it adds zero strength and can conceal advancing failure. Always pair with daily visual checks and load monitoring.

How often should strand end connectors be inspected in corrosive environments?

Minimum quarterly in marine or industrial zones (per NACE SP0106). In inland urban settings, biannual inspection suffices. Each inspection must include: (1) visual magnification (10× lens), (2) ultrasonic thickness scan, (3) torque verification of attachment bolts, and (4) documentation in a digital log with geo-tagged photos. Unrecorded inspections are not legally valid.

Conclusion: Safety Is a Process—Not a One-Time Decision

Understanding why strand end connectors fail isn’t academic—it’s the foundation for responsible intervention. Corrosion doesn’t announce itself with fanfare; it whispers through microscopic cracks and subtle dimensional changes. Mechanical failure doesn’t wait for scheduled maintenance—it accelerates silently under thermal stress and cyclic loading. Bypassing is never about convenience. It’s about applying rigorous engineering discipline when circumstances leave no margin for error. It demands calibrated tools, certified hardware, documented verification, and unwavering accountability. If your process lacks any of these elements, pause. Recalibrate. Consult a qualified PE. Because the true cost of a bypass isn’t measured in labor hours or hardware costs—it’s measured in trust, liability, and human safety. Start today: audit your next inspection checklist against ASTM F2567. Verify your torque tools are calibrated. Photograph every connector—not just the suspect ones. Build the habit of traceability. Your structure—and everyone who relies on it—depends on it.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?