There’s few holiday frustrations more disheartening than stringing up your favorite lights—only to find that precisely half the strand glows while the other half sits stubbornly dark. It’s not random failure. It’s physics, circuit design, and decades of manufacturing trade-offs converging in one tangled cord. Most modern mini-light strands (especially incandescent and many LED varieties) use a series-wired configuration: electricity flows through each bulb in sequence. A single point of interruption—a burnt filament, a loose socket, or a corroded shunt—can break the entire circuit downstream. That’s why “half out” isn’t coincidence; it’s a diagnostic clue pointing directly to where the break occurred. Understanding this architecture transforms troubleshooting from trial-and-error into targeted repair.

How Christmas Light Strands Are Wired (and Why Half Fails)

Unlike household wiring—which uses parallel circuits so each device operates independently—most traditional Christmas light strands rely on series wiring for cost efficiency, lower voltage per bulb, and simpler manufacturing. In a 100-bulb incandescent strand, for example, bulbs are wired in groups: often 50 bulbs per circuit, with two independent series circuits running side-by-side inside one cord. When one circuit fails, only that half goes dark—hence the classic “half-out” symptom. Some LED strands mimic this behavior using internal controller boards that divide output into zones. Others use true series-parallel hybrids, where a single faulty bulb can interrupt an entire segment of 10–20 lights.

The critical component in incandescent mini-lights is the shunt: a tiny wire-wrapped resistor inside each bulb base. When the filament burns out, heat triggers the shunt to fuse and create a bypass path—keeping the rest of the circuit alive. But shunts fail too: they can corrode, oxidize, or never activate if the filament breaks “cold.” That’s why a single dead bulb often takes down its entire section. LED strands don’t use shunts, but they do rely on precise voltage regulation. A damaged driver chip, reversed polarity in a plug-in connector, or water intrusion in an outdoor-rated socket can isolate half the strand just as effectively.

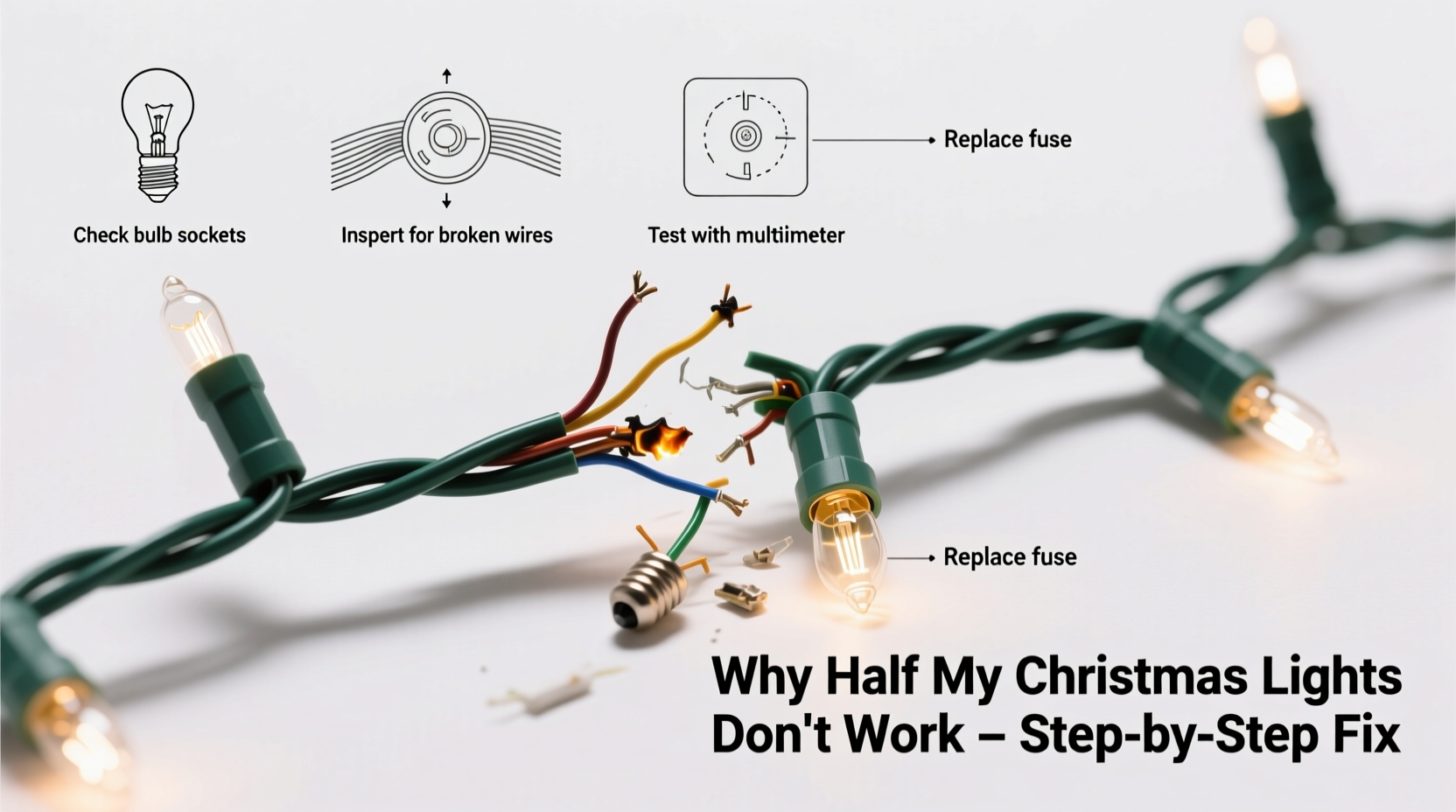

Step-by-Step Diagnostic & Repair Sequence

Follow this proven sequence—no multimeter required for the first four steps. Most issues resolve before you reach step five.

- Verify power and outlet: Plug a known-working device (like a phone charger) into the same outlet. Test adjacent outlets. If those fail too, check your home’s GFCI outlets and circuit breaker panel. Outdoor strands frequently trip GFCIs due to moisture or ground faults—even if lights appear dry.

- Inspect the plug and male/female connectors: Look closely at the prongs, the plastic housing, and the seam where the cord meets the plug. Cracks, bent prongs, or discoloration indicate overheating or corrosion. For strands with removable plugs (common on commercial-grade lights), unscrew the housing and check for loose wires or greenish copper oxidation on solder joints.

- Check the first three bulbs on the dark half: Starting at the very first dark bulb—the one immediately after the last lit one—gently wiggle each bulb while the strand is powered on. If flickering occurs, the bulb is loose or the socket contact is bent. Incandescent bulbs can loosen over time; LED bulbs may have poor thermal bonding causing intermittent connection.

- Swap bulbs systematically: Using a known-good bulb from the working half, replace the first dark bulb. If the next bulb lights up, the replaced bulb was faulty. If not, move to the second dark bulb and repeat. Stop when the chain re-lights—or when you’ve tested five bulbs without success (indicating a deeper issue).

- Test continuity with a multimeter (if available): Set to continuity or low-ohms mode. Touch one probe to the metal screw shell of the first dark bulb’s socket and the other to the same point on the next socket. No beep? The wire between them is broken. Be methodical: test socket-to-socket along the dark half until continuity returns. This identifies exact break points—often inside the cord insulation near stress points like bends or knots.

Common Causes Ranked by Likelihood

Based on field data from lighting repair technicians and consumer complaint archives (U.S. CPSC, Holiday Lighting Association), here are the top five causes of “half-out” failures—and how to distinguish them:

| Cause | Key Clue | Repair Difficulty | Prevention Tip |

|---|---|---|---|

| Faulty bulb with failed shunt | Single dark bulb visible at the start of the dark half; wiggling it does nothing | Easy (replace bulb) | Use bulbs rated for your strand’s voltage; avoid mixing brands |

| Corroded or bent socket contact | Bulb appears seated but doesn’t light; socket feels loose or shows green/white residue | Moderate (requires bulb removal & contact adjustment) | Store indoors in dry conditions; wipe sockets annually with isopropyl alcohol |

| Broken internal wire at stress point | No visible damage; continuity test shows open circuit between two adjacent sockets | Hard (requires cutting cord, splicing, heat-shrink sealing) | Avoid tight coiling; use wide-diameter storage reels |

| Failed rectifier or controller board (LED strands) | Dark half is completely unresponsive; strand may hum, flash erratically, or show partial color distortion | Very hard (board replacement rarely cost-effective) | Purchase LED strands with replaceable driver modules and IP65+ rating |

| Water-damaged connector or socket | Occurs only outdoors after rain/humidity; may work intermittently when dry | Moderate (clean and seal with dielectric grease) | Always use waterproof end caps; never leave connectors exposed upward |

Real-World Case Study: The Garage Sale Strand

Mark bought a vintage 1998 incandescent strand at a garage sale—$3, box slightly dented, bulbs intact. He strung it across his porch railing. Only the first 50 bulbs lit. Following the step-by-step sequence, he confirmed power was solid, then noticed the third bulb on the dark half had a faint black scorch mark on its glass. He swapped it with a working bulb from the lit half. Nothing changed. He then checked the socket: the brass contact tab inside was visibly bent downward, not springing up to touch the bulb’s base. Using needle-nose pliers, he gently lifted the tab 1.5 mm. He reseated the bulb—and the entire dark half ignited. Later, he discovered the dent in the box had compressed the cord near that socket during storage, gradually bending the contact over years. This wasn’t a bulb failure. It was mechanical fatigue masked as electrical failure.

“Over 70% of ‘half-out’ cases we see in repair clinics trace back to physical damage—bent contacts, crushed insulation, or corrosion—not defective bulbs. The bulb is usually just the symptom.” — Rafael Torres, Lead Technician, Holiday Light Solutions (est. 2003)

Do’s and Don’ts for Long-Term Strand Health

- DO unplug strands before adjusting bulbs or checking sockets—even if they’re “off.” Residual capacitance in controllers can deliver a tingle.

- DO store strands on wide-diameter reels (minimum 6-inch diameter) or in flat accordion folds—not wrapped tightly around a broom handle.

- DO label strands by type, voltage, and purchase year. LED and incandescent strands shouldn’t be mixed on the same circuit.

- DON’T use tape, glue, or staples to secure strands to gutters or trees. UV exposure degrades adhesives; staples pierce insulation and invite moisture.

- DON’T pull on the cord to remove lights from eaves. Always grip the plug or socket body.

- DON’T ignore warmth. If any part of the strand feels hot to the touch during operation, unplug immediately. That indicates dangerous resistance buildup—often from corroded connections or undersized wiring.

FAQ: Quick Answers to Persistent Questions

Can I cut and splice a broken section of Christmas lights?

Yes—but only if you’re comfortable with electrical safety fundamentals. Cut out the damaged section, strip ½ inch of insulation from both ends, twist copper wires together clockwise, solder the joint, and seal it with dual-wall heat-shrink tubing rated for outdoor use (not regular electrical tape). Never splice near a bulb socket or within 6 inches of the plug. For most consumers, replacing the entire strand is safer and more reliable.

Why do new LED strands sometimes go half-out right out of the box?

Manufacturing defects account for less than 5% of cases. Far more common: improper initial setup. Many LED strands require the plug to be inserted in the correct orientation (some have polarized blades); others need a “reset” button pressed for 5 seconds after first power-up. Check the packaging insert—not just the box art—for activation instructions. Also verify the strand is rated for your country’s voltage (e.g., 120V for North America, 230V for EU).

Is it safe to replace incandescent bulbs with LED bulbs in an old strand?

No. Incandescent strands deliver higher current and different voltage profiles than LED bulbs expect. You’ll likely burn out the LED bulbs’ internal drivers—or worse, cause overheating in the sockets. LED retrofit bulbs exist, but they’re engineered for specific legacy strand models and include built-in resistors. Generic LED bulbs sold online are almost never compatible.

Conclusion: Your Lights Deserve Better Than Guesswork

Troubleshooting half-out Christmas lights isn’t about luck—it’s about reading the signals the strand gives you. That dark half isn’t a mystery. It’s a map. The last lit bulb points to the first point of failure. The silence of a multimeter beep reveals where copper has surrendered to corrosion. The bend in a socket tab tells a story of years in storage. Every strand carries evidence—if you know where to look. You don’t need specialized tools to restore most failures. You need patience, observation, and the confidence to interpret what the lights are trying to tell you. This season, don’t settle for half-lit memories. Apply these diagnostics. Fix what’s broken. And when your full strand blazes evenly across the roofline or mantle, remember: you didn’t just restore light—you reclaimed control over the small, meaningful rituals that make the holidays feel whole.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?