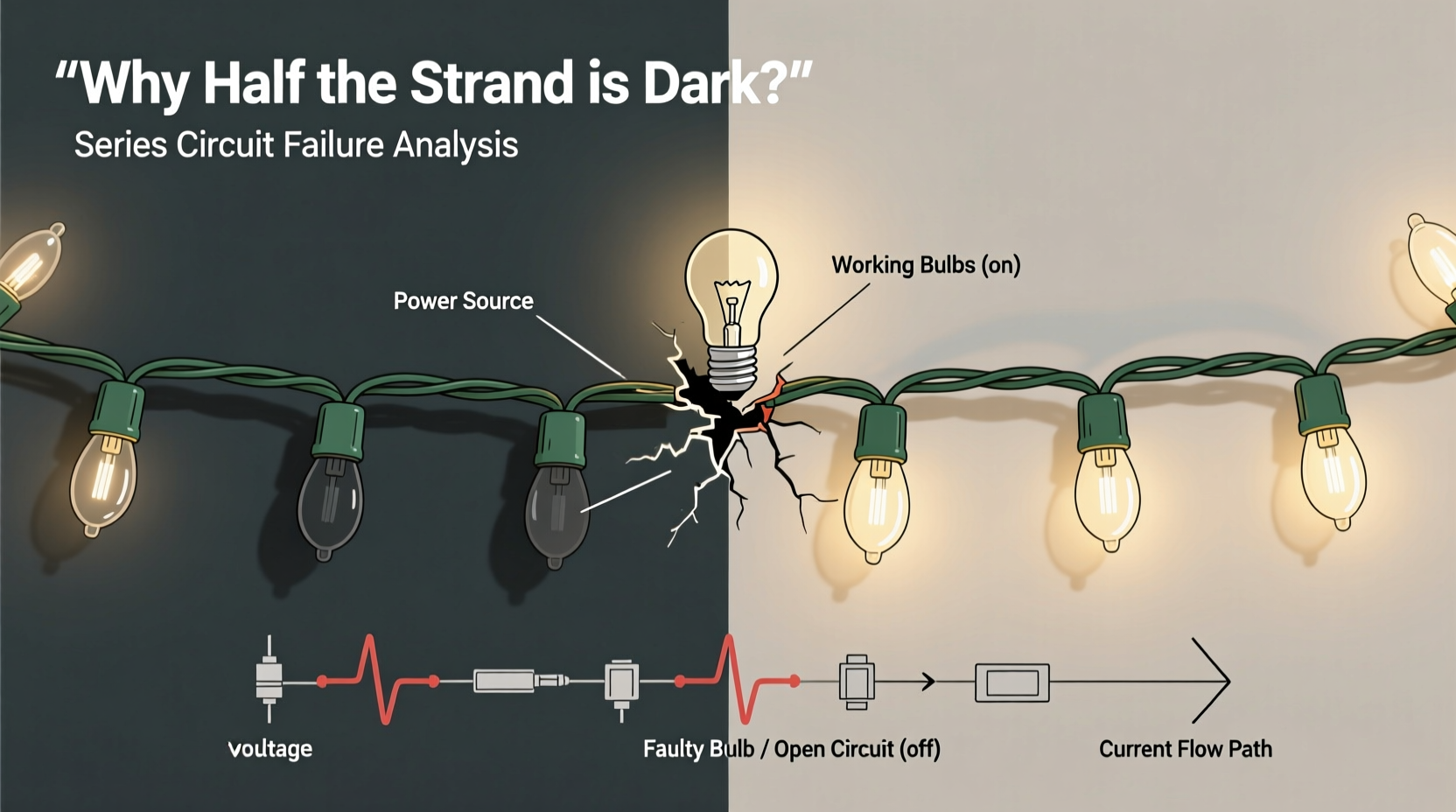

When you plug in your holiday lights and only the first 25 bulbs glow while the rest remain dark — or worse, the strand flickers erratically before dying mid-circuit — it’s rarely random bad luck. It’s physics. Specifically, it’s the unforgiving logic of a series circuit: one break, one failed filament, one loose connection, and the entire current path collapses downstream. Unlike modern parallel-wired LED strands (which isolate failures), traditional incandescent mini-light strings — still widely used for their warm glow and affordability — rely on series wiring. That means electricity must flow through every single bulb to complete the loop. When that loop is interrupted anywhere in the first half, everything beyond that point goes dark. Understanding this isn’t just about fixing lights — it’s about recognizing how design choices shape reliability, safety, and repairability.

How Series Circuits Work (and Why They’re So Fragile)

In a series circuit, all components — bulbs, resistors, fuses — are connected end-to-end in a single continuous path. Current has no alternative route. Voltage from the outlet (120V in North America) is divided across each bulb. For a standard 100-light incandescent strand, each bulb typically receives about 1.2 volts. This low per-bulb voltage allows safe operation but creates a critical vulnerability: if any bulb’s filament breaks, its socket opens the circuit. No current flows past that point — so every bulb downstream stays dark. Crucially, the “half” that goes out isn’t arbitrary. It reflects where the break occurred *in the physical wiring sequence*, not where the bulbs are spaced along the cord. Most traditional strands wire bulbs in groups of 50, with a “shunt” built into each socket — a tiny coiled wire designed to activate when the filament fails, bridging the gap and keeping the rest lit. But shunts fail too — especially after years of thermal cycling, corrosion, or moisture exposure.

The 5 Most Common Causes (Ranked by Likelihood)

Based on field data from electrical contractors and holiday light repair specialists, these causes account for over 90% of “half-out” failures in vintage-style mini-light strands:

- Filament failure with shunt bypass failure — The bulb’s tungsten filament burns out, but the internal shunt doesn’t activate due to oxidation or manufacturing defect.

- Loose or oxidized bulb socket contacts — Vibration, temperature swings, and humidity cause metal contacts to corrode or loosen, creating high-resistance points that interrupt current.

- Broken wire inside the cord (especially near plugs or connectors) — Repeated bending at stress points fractures internal conductors. You’ll often see discoloration or stiffness in the cord.

- Blown inline fuse (usually in the male plug) — Many strands include two 3-amp fuses; one may blow while the other remains intact, cutting power to half the circuit.

- Failed rectifier or controller (in multi-function strands) — Strands with chasing, twinkling, or color-changing modes use small circuit boards. A failed diode or capacitor can disable one leg of a split-series design.

Step-by-Step Diagnostic Protocol

Follow this methodical, safety-conscious sequence — no special tools required beyond a multimeter (optional but highly recommended) and a known-good replacement bulb:

- Unplug the strand immediately. Never work on live circuits. Verify no other strands are daisy-chained.

- Inspect the plug and fuses. Open the male plug housing (usually two screws). Check both ceramic fuses for visible breaks or darkened glass. Replace with identical-rated fuses only.

- Locate the first dark bulb. Starting from the plug end, move down the strand until you find the last working bulb. The problem lies at or immediately after this bulb — in its socket, the bulb itself, or the next socket.

- Test the suspect bulb. Remove it and insert a known-good bulb. If the strand lights fully, the removed bulb was faulty. If not, the issue is in the socket or wiring.

- Check socket continuity. With the strand unplugged, gently wiggle each bulb in the dark section. If lights flicker or briefly illuminate, the contact is loose. Clean socket contacts with isopropyl alcohol and a cotton swab — never sandpaper.

- Verify shunt activation (advanced). Using a multimeter on continuity mode, test across the two contacts of a dark-bulb socket. A reading near 0 ohms indicates the shunt is active; infinite resistance means it failed. Replace the bulb — even if it looks fine.

Do’s and Don’ts: A Practical Comparison Table

| Action | Do | Don’t |

|---|---|---|

| Bulb replacement | Use exact-voltage, same-base bulbs (e.g., 2.5V, T1¾, wedge base). Match wattage. | Substitute higher-wattage bulbs — they overheat sockets and accelerate shunt failure. |

| Cleaning contacts | Use 91% isopropyl alcohol and lint-free cloth. Let sockets dry completely before reassembly. | Use vinegar, baking soda paste, or abrasive cleaners — they leave residue or damage plating. |

| Storage | Wind loosely around a cardboard tube; store in climate-controlled, low-humidity space. | Wrap tightly around a spool or store in damp garage — accelerates corrosion and insulation brittleness. |

| Daisy-chaining | Never exceed manufacturer’s max strand count (usually 3–5 strands). Check UL listing. | Chain more than recommended — cumulative voltage drop and heat buildup risk fire hazard. |

| Troubleshooting tools | Use a non-contact voltage tester to verify power reaches the plug; a bulb tester to confirm socket function. | Rely solely on visual inspection — 70% of failures show no visible damage. |

Real-World Case Study: The “Ghost Half” Strand

Martha, a school art teacher in Portland, Oregon, brought a 20-year-old red-and-green incandescent strand to her local hardware store’s holiday light clinic. The first 50 bulbs glowed steadily. The next 50 were dark — but when she gently tapped the 51st socket, the entire second half flashed brightly for two seconds before dying again. The technician didn’t replace bulbs first. Instead, he checked the fuse (intact), then measured voltage at the 50th socket: 1.2V (normal). At the 51st socket’s input: 0V. The break wasn’t in the bulb — it was in the wire connecting socket 50 to 51. A microscopic copper fracture, hidden under insulation, opened under vibration. He cut out the damaged 2-inch segment, spliced in new wire with solder and heat-shrink tubing, and retested. Full illumination restored. Martha’s strand worked for three more seasons. Her takeaway? “The tap wasn’t magic — it was physics revealing a high-resistance fault. I’d been replacing bulbs for months, wasting time and money.”

Expert Insight: What Electricians Wish You Knew

“Series mini-lights aren’t ‘broken’ — they’re operating exactly as designed. The real issue is treating them like disposable decor. A $12 strand with proper care lasts 8–10 years. The biggest killer isn’t age — it’s moisture ingress during storage and thermal stress from rapid on/off cycling. Always unplug before adjusting bulbs, and never run them 24/7.” — Carlos Mendez, Master Electrician & Holiday Lighting Safety Advisor, NFPA Electrical Code Committee

Preventive Maintenance Checklist

Perform these actions annually, before storing or deploying lights:

- ✅ Visual inspection: Scan for cracked bulbs, frayed cord near plugs, discolored sockets, or bent pins.

- ✅ Socket cleaning: Dip cotton swab in isopropyl alcohol; wipe all socket contacts. Dry 5 minutes.

- ✅ Fuse verification: Test both fuses with a multimeter or bulb tester. Keep spares on hand.

- ✅ Shunt verification (for critical strands): Use continuity tester on every socket in dark sections — flag those with open circuits.

- ✅ Cord flexibility check: Gently bend cord every 6 inches. Discard if stiff, cracked, or emits plastic odor.

- ✅ Label & organize: Tag strands by type, voltage, and year acquired. Store separately by function (e.g., roof vs. tree).

FAQ: Your Top Questions Answered

Can I convert a series strand to parallel wiring?

No — and attempting it is dangerous. Series strands lack the voltage regulation, current-limiting resistors, and insulation ratings required for parallel operation at line voltage. Rewiring voids UL certification and creates shock/fire hazards. Upgrade to purpose-built parallel LED strands instead.

Why do some bulbs glow dimly while others are dark?

Dim glow usually indicates a failing shunt or partial filament break — current is leaking but insufficient to fully illuminate downstream bulbs. It’s an early warning sign. Replace the bulb immediately; don’t wait for total failure.

Is it safe to use LED replacement bulbs in an incandescent series strand?

Only if explicitly rated as “series-compatible LED” with built-in current-limiting resistors. Standard LED bulbs draw far less current, causing voltage to spike across remaining incandescent bulbs — overheating them and shortening lifespan. Mismatched LEDs also prevent shunts from activating correctly.

Conclusion: Respect the Circuit, Extend the Season

That half-dark strand isn’t a nuisance — it’s a lesson in electrical fundamentals, material science, and mindful consumption. Every flicker, every cold socket, every blown fuse tells a story about how energy moves, how metals fatigue, and how design choices ripple through years of use. Troubleshooting series lights isn’t about memorizing steps — it’s about cultivating observation, patience, and respect for the invisible current that powers our celebrations. When you restore a strand not by replacing it, but by diagnosing its quiet failure, you reclaim agency over the objects we too often treat as ephemeral. You extend not just the life of lights, but the warmth of tradition, the joy of reuse, and the quiet satisfaction of solving what others discard. So this season, before you reach for the trash bin or the new-box discount, pause. Unplug. Inspect. Test. And remember: electricity always follows the path of least resistance — but understanding takes the path of careful attention.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?