Candles are more than just sources of light—they create ambiance, enhance mood, and often serve as thoughtful decor. But nothing ruins the experience faster than a candle that burns down the center, leaving thick walls of wax untouched along the edges. This phenomenon, known as \"tunneling,\" not only wastes wax but also shortens the candle’s lifespan and diminishes its fragrance throw. Understanding why tunneling occurs—and how to prevent or correct it—is essential for anyone who values quality candle use.

Tunneling typically happens when a candle forms a deep well in the middle while the outer rim remains solid. Over time, this creates a narrow channel that limits the melt pool and prevents the wick from drawing fuel efficiently. The good news? Most tunneling issues are avoidable with proper technique and awareness. Let’s explore the root causes, practical fixes, and long-term prevention strategies.

Understanding Candle Tunneling: What It Is and Why It Happens

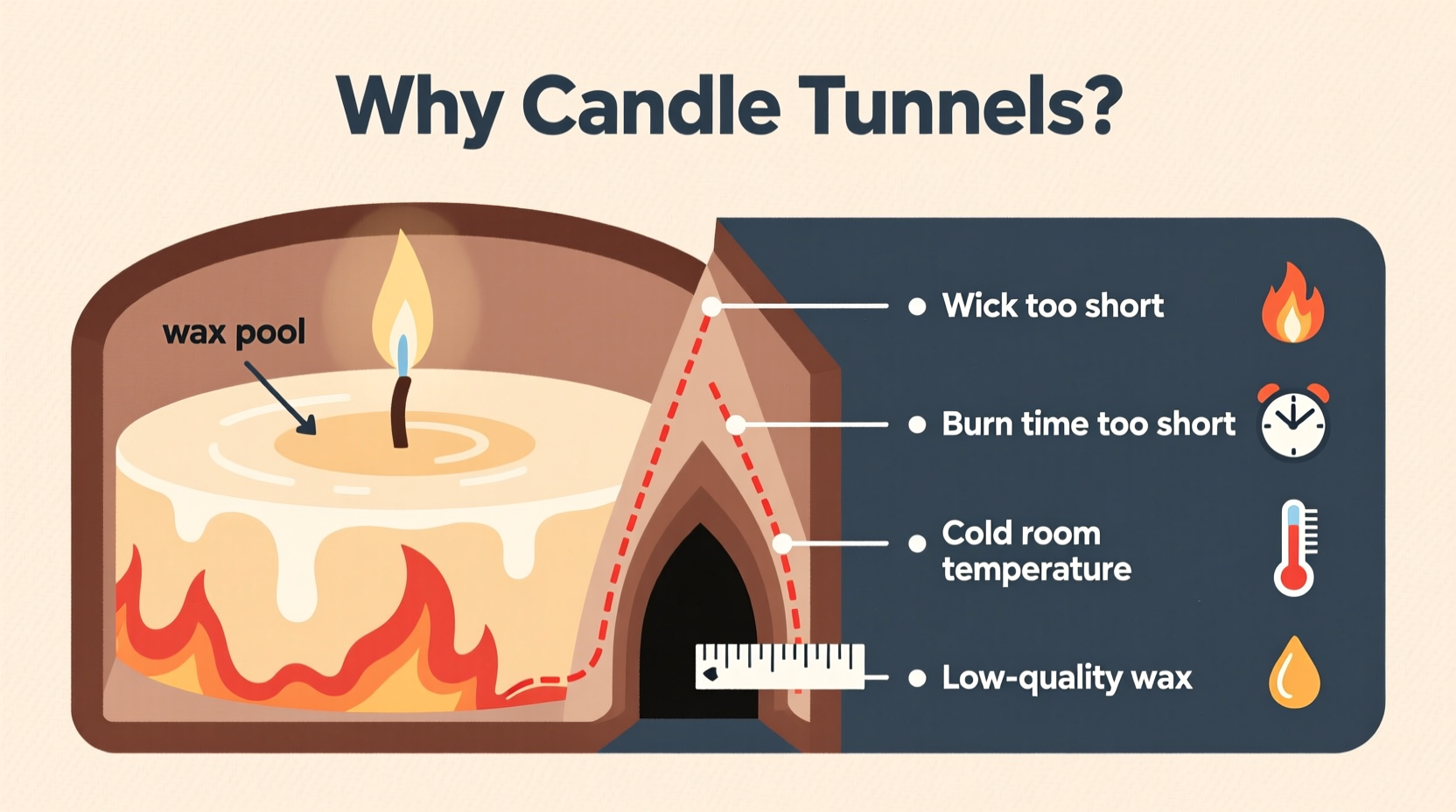

Candle tunneling occurs when the flame melts wax only in a small circle around the wick, failing to reach the container's edges. This results in a \"tunnel\" effect where unused wax builds up on the sides over successive burns. While it may seem like a flaw in the candle itself, tunneling is usually the result of improper burning habits rather than a manufacturing defect.

The primary cause lies in the initial burn. When a candle is lit for the first time, the wax near the wick melts quickly, forming a pool. If this pool doesn’t extend all the way to the edge of the container during the first burn, subsequent burns will follow the same pattern—deepening the existing well without ever melting the outer wax. This behavior is especially common in container candles made from soy, paraffin, or coconut blends, which have lower melting points and require careful temperature management.

Several factors contribute to tunneling:

- Inadequate first burn time: Not allowing the candle to form a full melt pool across the surface during its debut lighting.

- Short burn cycles: Lighting the candle for too brief a period (e.g., 30–60 minutes) repeatedly prevents even heat distribution.

- Wick size mismatch: A wick that’s too small for the diameter of the candle won’t generate enough heat to melt wax laterally.

- Poor airflow or drafts: Drafts can cool one side of the candle faster, causing uneven melting.

- Candle composition: Some natural waxes like soy tend to tunnel more easily if not burned correctly.

“Candle performance starts with the very first burn. Get that wrong, and you're setting yourself up for tunneling no matter what you do later.” — Laura Benson, Artisan Candlemaker & Founder of Hearth & Wick Co.

How to Fix a Tunneling Candle: Step-by-Step Recovery Guide

If your candle has already started tunneling, don’t discard it just yet. With some patience and technique, you can rehabilitate it and restore an even burn. Here’s a reliable method used by candle care experts to correct tunneling.

Step 1: Assess the Depth of the Tunnel

Determine how deep the well is and whether there’s still usable wax trapped around the sides. If the tunnel is deeper than ½ inch, recovery will take multiple sessions.

Step 2: Trim the Wick

Cut the wick to ¼ inch before attempting any correction. A properly trimmed wick ensures clean combustion and optimal flame height.

Step 3: Use Aluminum Foil (Recommended Method)

This widely trusted technique helps trap heat and direct it toward the outer wax walls:

- Take a sheet of aluminum foil and shape it into a collar that fits over the top of the candle jar.

- Leave a small opening in the center to allow oxygen flow to the flame.

- Ensure the foil touches the glass walls to help conduct heat into the unmelted wax.

- Light the candle and let it burn for 2–4 hours, monitoring closely.

- Extinguish the flame once the melt pool reaches the edges.

- Repeat every few days until the tunnel is fully corrected.

Step 4: Rotate the Candle (Optional)

If one side consistently fails to melt, gently rotate the candle 90 degrees every 30 minutes during a burn session. This promotes even exposure to ambient temperature and minimizes cold spots.

Step 5: Allow Full Cooling Between Burns

After each corrective burn, extinguish the flame and let the candle cool completely—ideally for at least 6–8 hours. Rushing into another burn cycle disrupts wax re-solidification and undermines progress.

Prevention Checklist: How to Avoid Tunneling from Day One

Preventing tunneling is far easier than fixing it. Follow this actionable checklist to ensure every candle burns cleanly and efficiently from the start.

| Action | Why It Matters | Frequency |

|---|---|---|

| Allow first burn to last long enough to form full melt pool | Establishes memory ring; prevents future tunneling | First burn only |

| Burn for 1 hour per inch of candle diameter | Ensures complete lateral melt without overheating | Every burn |

| Trim wick to ¼ inch before each lighting | Controls flame size and soot production | Before every use |

| Avoid drafty areas | Prevents flickering and uneven cooling | Ongoing |

| Keep away from vents, fans, or open windows | Maintains consistent burn temperature | Ongoing |

| Store upright in cool, dry place | Preserves wax integrity and scent stability | When not in use |

Real-World Example: Recovering a Soy Wax Candle

Sarah purchased a premium 14-ounce soy candle labeled as having a 50-hour burn time. Excited to try it, she lit it for about 45 minutes each evening after work. After three uses, she noticed a growing tunnel nearly half an inch deep, with hard wax clinging to the sides. Frustrated, she almost gave up—until she researched candle care and discovered her mistake: under-burning.

She followed the aluminum foil recovery method. On the fourth night, she wrapped the jar with foil, leaving a small vent above the flame. She allowed the candle to burn for 3.5 hours—the longest session yet. By the end, the melt pool had expanded to within a quarter-inch of the rim. She repeated the process two more times, reducing foil coverage as progress improved. Within a week, the candle burned evenly, released fragrance beautifully, and ultimately lasted close to its advertised lifespan.

Sarah now applies the “one hour per inch” rule religiously and trims her wicks without fail. Her collection of candles lasts longer, performs better, and enhances her space more effectively.

Do’s and Don’ts of Candle Burning

To reinforce best practices, here’s a quick-reference guide summarizing key behaviors to adopt—and those to avoid.

| Do’s | Don’ts |

|---|---|

| Let the first burn last 2–4 hours (depending on size) | Never burn for less than 1 hour unless testing |

| Always trim the wick before lighting | Don’t ignore mushrooming or carbon buildup |

| Place candle on stable, heat-resistant surface | Don’t move a burning candle |

| Use a wick dipper or snuffer to extinguish flame | Don’t blow out candles (causes smoke and splatter) |

| Check manufacturer’s burn recommendations | Don’t assume all candles behave the same |

Frequently Asked Questions

Can I fix tunneling permanently?

Yes, in most cases. Once you correct the tunnel using heat-retaining methods like foil wrapping and establish proper burn discipline, the candle should resume even melting. However, if the wick is inherently undersized or the wax blend is problematic, full recovery may not be possible.

How long should I burn a candle to prevent tunneling?

A general rule is to burn your candle for **one hour for every inch of its diameter**. For example, a 3-inch wide candle needs at least 3 hours per burn session to develop a full melt pool. Never exceed 4 hours at a time to avoid overheating the container or wick.

Is tunneling worse with certain types of wax?

Yes. Soy wax, while eco-friendly and clean-burning, has a lower melting point and tends to tunnel more easily if not burned properly. Paraffin holds heat better but produces more soot. Beeswax resists tunneling naturally due to its high melting point but is denser and pricier. Coconut-blend waxes offer a balanced alternative with excellent scent throw and reduced tunneling risk.

Final Thoughts: Master Your Candle Care Routine

Candle tunneling isn't a sign of poor quality—it's usually a signal that burn habits need adjustment. From the crucial first burn to consistent wick maintenance, every step influences how evenly your candle consumes its wax. By understanding the science behind melting patterns and applying proven techniques, you transform candle lighting from a passive ritual into an intentional act of care.

Whether you're lighting a simple tea light or savoring a luxury-scented jar candle, treating it with attention ensures maximum enjoyment, safety, and value. Don’t let tunneling cut your candle’s life short. Start today: check your current candles, assess their burn history, and apply these strategies to get the most out of every flame.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?