Electricity powers nearly every aspect of modern life, from homes and hospitals to transportation and communication. At the heart of this vast energy network are generators—machines that convert mechanical energy into electrical energy. A key component enabling this transformation is the electromagnet. Unlike permanent magnets, electromagnets provide dynamic control, scalability, and higher efficiency, making them essential in almost all modern generator designs. Understanding why generators rely on electromagnets reveals not only the science behind power generation but also the engineering rationale for optimizing performance, reliability, and adaptability in diverse applications.

The Role of Magnetism in Electricity Generation

Generators operate on the principle of electromagnetic induction, discovered by Michael Faraday in 1831. When a conductor moves through a magnetic field—or when the magnetic field around a conductor changes—an electric current is induced in the conductor. This fundamental law underpins all generator technology.

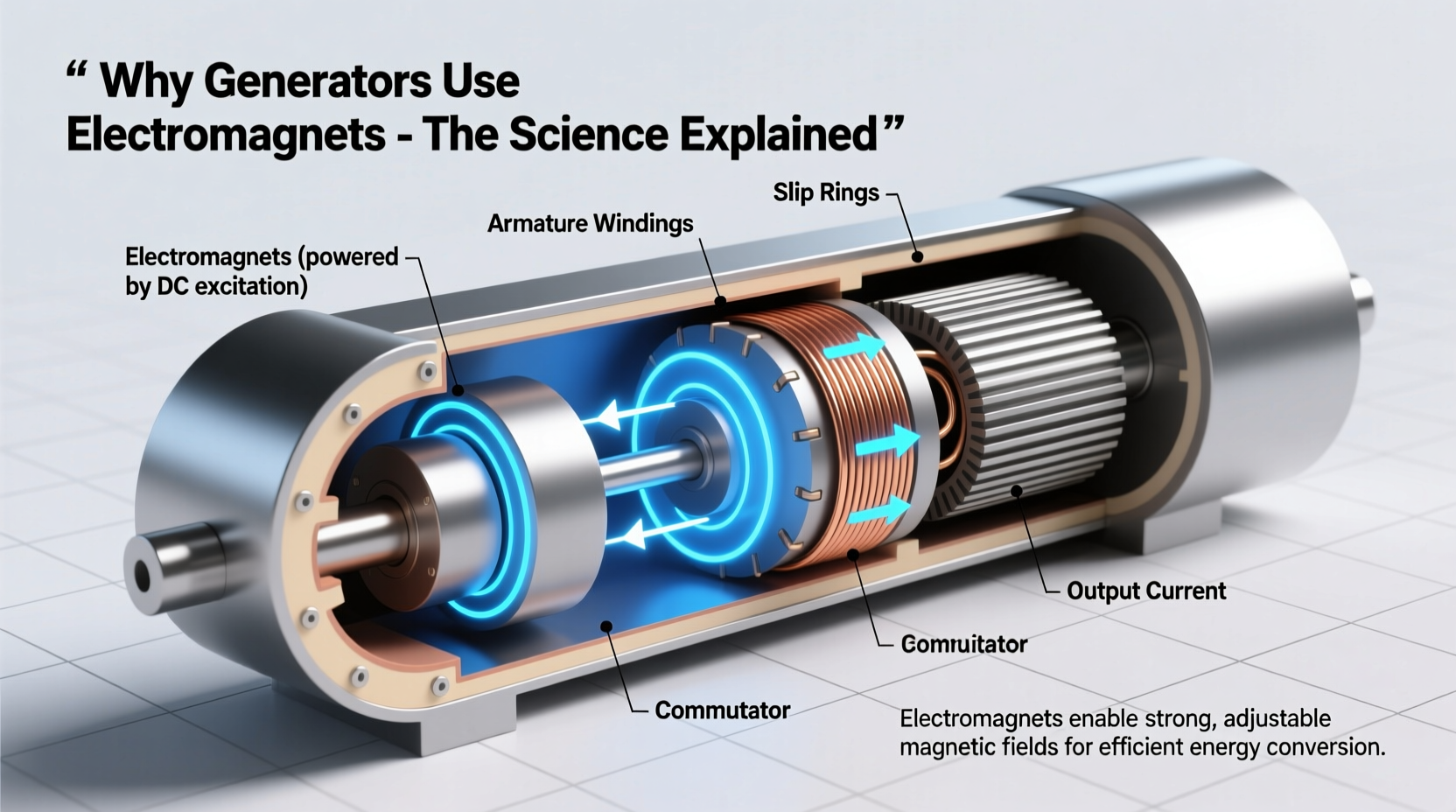

In practical terms, a generator consists of two main parts: the rotor (the rotating component) and the stator (the stationary part). The magnetic field required for induction can be created either by permanent magnets or electromagnets. While small-scale or specialized generators may use permanent magnets, industrial and commercial power generators almost universally use electromagnets due to their superior controllability and power output capabilities.

Why Electromagnets Outperform Permanent Magnets

Permanent magnets generate a fixed magnetic field without external input. While useful in compact devices like bicycle dynamos or small wind turbines, they lack the flexibility needed for large-scale electricity production. Electromagnets, on the other hand, generate a magnetic field only when an electric current flows through a coil of wire—typically wrapped around a ferromagnetic core like iron.

This ability to control the magnetic field by adjusting the current provides several critical advantages:

- Adjustable Field Strength: Operators can regulate voltage output by varying the current supplied to the electromagnet.

- Higher Magnetic Flux Density: Electromagnets can produce much stronger fields than most permanent magnets, especially when energized with high currents.

- On/Off Capability: The magnetic field can be turned off during maintenance or emergencies, enhancing safety and operational control.

- Scalability: Electromagnets can be engineered for massive power plants or portable units without compromising performance.

How Electromagnets Are Used in Generator Design

In most AC generators (alternators), the electromagnet is mounted on the rotor, while the stator contains the conductive coils where electricity is generated. This configuration, known as a \"rotating field\" design, offers significant benefits:

- The rotor requires only a small DC current (called excitation current) to energize the electromagnet, which can be supplied via slip rings and brushes or through brushless excitation systems.

- The high-power AC output is drawn directly from the stationary stator windings, eliminating the need for large, unreliable sliding contacts that would otherwise carry heavy currents.

- Heat generated in the rotor is easier to manage because the electromagnet doesn’t handle the full output load.

This setup allows for efficient, reliable, and high-capacity power generation used in everything from diesel backup generators to hydroelectric dams and gas turbines.

Brushless Excitation Systems: Modern Efficiency

Many modern generators employ brushless excitation, which eliminates physical contact between moving and stationary parts. In this system, a small auxiliary generator (exciter) mounted on the same shaft produces DC power that feeds the main rotor’s electromagnet through a rectifier. This design reduces maintenance, improves reliability, and extends service life—especially important in remote or critical infrastructure settings.

“Electromagnets give us real-time control over voltage regulation and reactive power support, which is vital for grid stability.” — Dr. Alan Reyes, Power Systems Engineer at GridTech Solutions

Advantages of Using Electromagnets in Generators

The shift from permanent magnets to electromagnets in mainstream generator technology wasn’t arbitrary—it was driven by measurable improvements in functionality and performance. Below is a comparison highlighting key advantages:

| Feature | Electromagnets | Permanent Magnets |

|---|---|---|

| Magnetic Field Control | Adjustable via current input | Fixed strength |

| Voltage Regulation | Precise and responsive | Limited; requires external electronics |

| Power Output Scalability | Highly scalable for large systems | Limited by magnet size and material |

| Failure Management | Field can be de-energized safely | Always active; poses risks during repair |

| Cost Efficiency (Large Scale) | Lower long-term cost per kW | Expensive rare-earth materials |

| Maintenance Needs | Low with brushless systems | Minimal, but brittle magnets can fail |

These factors make electromagnets the preferred choice in utility-scale power generation, where consistency, safety, and adaptability are paramount.

Real-World Application: Electromagnets in Emergency Power Systems

Consider a hospital relying on a backup diesel generator during a city-wide blackout. When the main power fails, the generator starts automatically. However, delivering stable electricity isn’t just about spinning a rotor—it’s about maintaining consistent voltage and frequency despite sudden load changes (e.g., life-support machines turning on).

In this scenario, the electromagnet in the generator’s rotor is energized by a controlled DC supply. As demand fluctuates, sensors monitor output voltage and feed data to an automatic voltage regulator (AVR). The AVR adjusts the excitation current to the electromagnet in real time, strengthening or weakening the magnetic field as needed to keep voltage steady.

Without this dynamic control—something permanent magnets cannot offer—the generator might deliver unstable power, risking equipment damage or failure. This example illustrates how electromagnets aren’t just components—they’re intelligent elements enabling mission-critical reliability.

Step-by-Step: How an Electromagnet Powers Up a Generator

Understanding the sequence of events helps clarify the electromagnet’s central role:

- Startup Signal: The generator receives a start command (manual or automatic).

- Rotor Rotation Begins: An engine or turbine begins turning the rotor shaft.

- Excitation Initiated: A small DC current is sent to the electromagnet coil via slip rings or a brushless exciter.

- Magnetic Field Builds: The energized coil creates a strong, controllable magnetic field around the rotor. <5> Induction Occurs: As the rotor spins, its magnetic field cuts across the stator windings, inducing alternating current.

- Voltage Regulation: The AVR continuously monitors output and adjusts excitation current to maintain stable voltage.

- Power Delivery: Clean, regulated AC power is delivered to connected loads.

This entire process hinges on the electromagnet’s ability to respond instantly to control signals—a feature impossible with static permanent magnets.

Frequently Asked Questions

Can generators work with permanent magnets instead?

Yes, small generators like those in portable units or micro-wind turbines often use permanent magnets. However, they lack voltage regulation and are unsuitable for large-scale or grid-connected applications where stability is crucial.

Do electromagnets consume power themselves?

Yes, they require a small amount of DC power (excitation current) to function. But this loss is minimal compared to the total output—typically less than 2%—and is far outweighed by gains in control and efficiency.

Are electromagnets more expensive to maintain?

Traditional brushed systems require periodic maintenance, but modern brushless designs have significantly reduced upkeep. Overall, electromagnet-based generators offer better long-term value due to durability and performance.

Checklist: Key Benefits of Electromagnets in Generators

- ✅ Adjustable magnetic field strength for precise voltage control

- ✅ Compatibility with automatic voltage regulators (AVRs)

- ✅ Ability to shut down the magnetic field for safer maintenance

- ✅ Higher power density suitable for industrial applications

- ✅ Integration with smart grid technologies for reactive power management

- ✅ Long operational life with proper excitation system design

Conclusion: The Electromagnet as a Pillar of Modern Power

The use of electromagnets in generators is not merely a technical detail—it’s a cornerstone of reliable, scalable, and intelligent power generation. From blackouts to peak demand surges, electromagnets enable generators to respond dynamically, ensuring that electricity remains stable and accessible. Whether in a remote village or a metropolitan skyline, the silent precision of an electromagnet inside a spinning rotor plays a vital role in keeping the lights on.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?