Soldering is a foundational skill in electronics, plumbing, and metalwork, but even experienced technicians can struggle with weak or inconsistent joints. One often-overlooked factor that determines the success of any soldering job is flux. While it may seem like a minor chemical additive, flux plays a pivotal role in ensuring strong, conductive, and durable connections. Without it, oxidation and contamination can compromise even the most carefully applied solder. Understanding why flux is essential—and how to use it properly—can dramatically improve your results.

The Role of Flux in Soldering

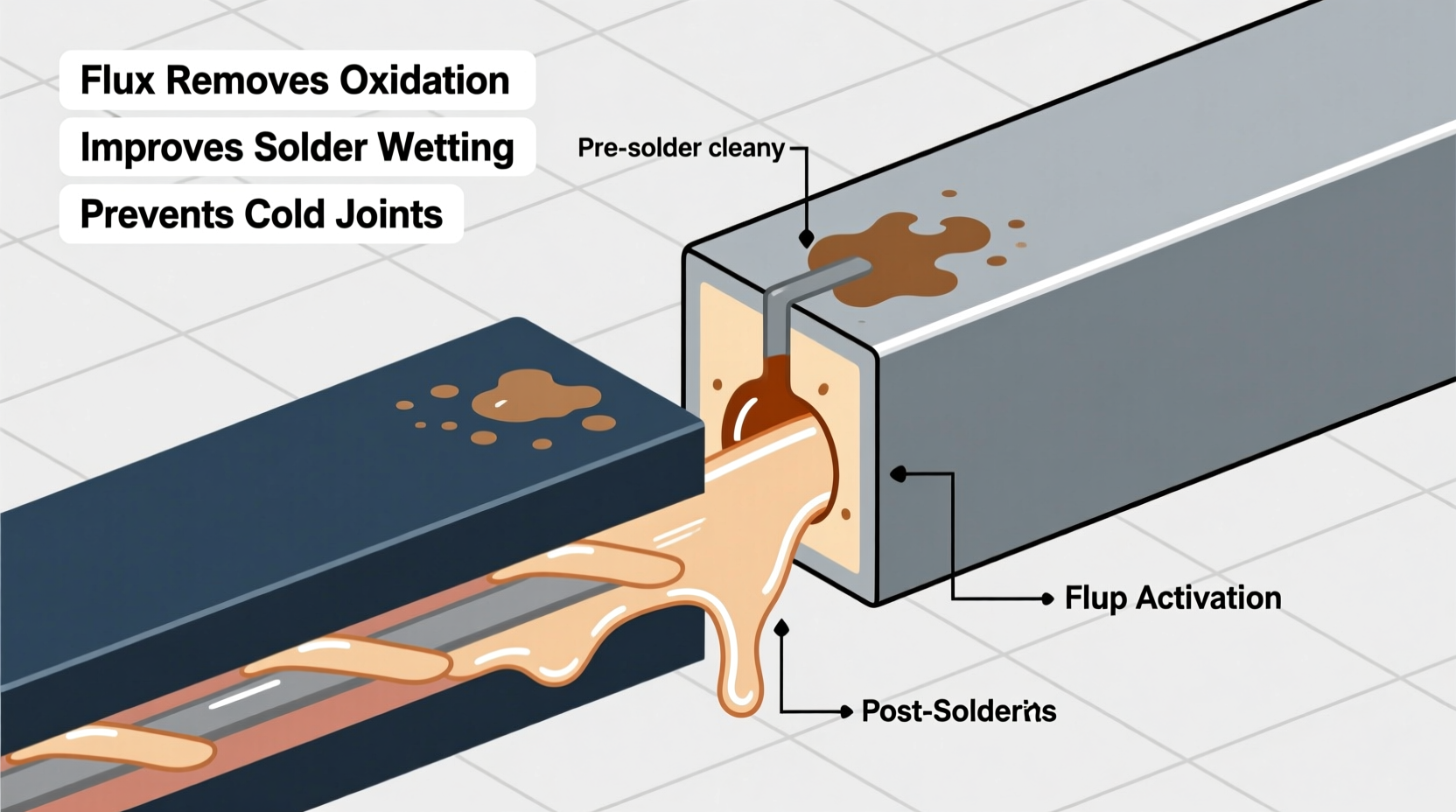

At its core, flux is a chemical agent designed to prepare metal surfaces for soldering by removing oxides and preventing further oxidation during heating. When metals are exposed to air, especially at elevated temperatures, they form oxide layers that inhibit the flow and adhesion of molten solder. These oxides act as barriers, resulting in poor wetting, cold joints, and unreliable electrical or mechanical connections.

Flux breaks down these oxides, cleans the surface, and promotes uniform solder flow. It also reduces surface tension, allowing the solder to spread evenly across the joint. This leads to smoother, shinier, and more conductive bonds. In essence, flux doesn’t just assist the process—it enables successful soldering under real-world conditions where perfect cleanliness and inert atmospheres aren't feasible.

“Flux is the unsung hero of soldering. A perfect iron and premium solder won’t save you if the joint surface is contaminated or oxidized.” — David Lin, Senior Electronics Technician at CircuitWorks Labs

Key Benefits of Using Flux

Using flux isn’t optional for professional-grade work—it’s essential. Here are the primary advantages it provides:

- Oxide Removal: Flux chemically reacts with metal oxides, dissolving them and exposing clean base metal for optimal solder adhesion.

- Oxidation Prevention: During soldering, flux forms a protective barrier over the heated metal, shielding it from oxygen and minimizing new oxide formation.

- Improved Wetting: By reducing surface tension, flux allows molten solder to flow smoothly and adhere uniformly across the joint.

- Better Joint Integrity: Clean, well-wetted joints are mechanically stronger and electrically more reliable, reducing the risk of failure in critical circuits.

- Error Reduction: Proper flux use decreases the likelihood of cold joints, bridging, and incomplete connections—common issues in hand-soldering.

Types of Flux and Their Applications

Not all fluxes are created equal. Different formulations serve different purposes depending on the material being soldered and the environment. The three main types are:

| Type | Composition | Best For | Clean-Up Required? |

|---|---|---|---|

| Rosin Flux (R, RMA) | Derived from pine sap; mildly active | Electronics, PCB assembly | Yes – recommended for sensitive circuits |

| Water-Soluble Flux | Organic acids; highly active | High-reliability boards, power electronics | Yes – must be cleaned with water |

| No-Clean Flux | Low-residue synthetic compounds | Consumer electronics, rework | No – safe for leaving on board |

Choosing the right type depends on your application. For example, rosin-based flux is ideal for delicate circuit boards due to its moderate activity and ease of removal. Water-soluble flux offers superior cleaning power but requires thorough post-soldering rinsing. No-clean flux is convenient for high-volume production but may leave residues that interfere with testing probes or conformal coatings.

Step-by-Step Guide to Using Flux Effectively

To maximize the benefits of flux, follow this proven sequence:

- Prepare the Surface: Lightly clean the metal with isopropyl alcohol and a lint-free cloth to remove oils and dust.

- Apply Flux: Use a fine-tip applicator or flux pen to deposit a small amount directly onto the joint area—just enough to cover the connection points.

- Heat the Joint: Apply the soldering iron to both components simultaneously, ensuring even heat distribution.

- Feed the Solder: Introduce the solder wire to the heated side opposite the iron tip. The flux will activate, and the solder should flow smoothly into the joint.

- Inspect and Clean (if needed): Check for shiny, concave fillets. If using rosin or water-soluble flux, clean residue with appropriate solvents.

Common Mistakes and How to Avoid Them

Even skilled users sometimes misuse flux, undermining their results. Here are frequent errors and corrections:

- Mistake: Skipping flux entirely because the solder has a flux core.

Solution: Core flux helps, but additional external flux ensures complete coverage, especially on larger or oxidized joints. - Mistake: Using electronics flux on plumbing or stained glass projects.

Solution: Acid-based fluxes used in plumbing can damage circuits. Always match flux type to material and application. - Mistake: Failing to clean corrosive residues.

Solution: Leftover activated flux can cause long-term corrosion. Clean with 90%+ isopropyl alcohol or specialized flux removers.

Mini Case Study: Repairing a Cold Joint on a Power Supply Board

A technician was troubleshooting a failing DC power supply module exhibiting intermittent output. Visual inspection revealed a dull, lumpy solder joint on a MOSFET drain pad—classic signs of a cold joint. After desoldering and cleaning the pad, he applied a small drop of no-clean flux, reheated the joint evenly, and reapplied solder. The result was a smooth, shiny fillet with full pad coverage. Post-repair testing showed stable voltage output and improved thermal conductivity. The addition of flux made the difference between a marginal repair and a lasting fix.

FAQ

Can I solder without flux?

You can physically melt solder onto metal without flux, but the joint will likely be weak, brittle, and unreliable due to poor wetting and oxide interference. Flux is especially critical when working with aged or non-pre-tinned components.

Is flux dangerous to handle?

Most modern fluxes are safe when used in ventilated areas and with basic precautions. However, some contain mild irritants. Avoid skin contact and inhalation of fumes. Rosin fumes, in particular, can trigger respiratory sensitivity in some individuals over time.

Why does my solder ball up instead of flowing?

This typically indicates surface oxidation or contamination. Even with a heated iron, solder won’t adhere properly without flux to clean the interface. Reapply flux and reheat the joint for better results.

Checklist: Best Practices for Flux Usage

- ✔ Choose the correct flux type for your material and application

- ✔ Apply flux before heating—not after

- ✔ Use only the necessary amount to avoid mess and residue buildup

- ✔ Clean residue when required (especially with rosin or water-soluble types)

- ✔ Store flux in a cool, dark place to prevent degradation

- ✔ Never reuse open flux containers that have been contaminated

Conclusion

Flux is far more than a supplementary chemical—it's a fundamental component of successful soldering. From enabling clean metal-to-metal bonding to preventing defects that lead to field failures, its role cannot be overstated. Whether you're assembling a prototype, repairing a vintage radio, or building industrial controls, taking the time to use flux correctly pays dividends in reliability, efficiency, and performance.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?