Christmas villages bring warmth, nostalgia, and quiet magic to holiday displays — but nothing disrupts that charm faster than a silent, dark row of miniature houses. When your village stays stubbornly unlit, it’s rarely a sign of faulty craftsmanship or doomed decor. More often, it’s a simple, solvable issue rooted in electrical continuity: loose plugs, overloaded circuits, degraded wiring, or overlooked safety features. Unlike standard string lights, village systems involve layered power distribution — transformers, daisy-chained buildings, accessory adapters, and sometimes even battery backups or wireless controllers. That complexity means troubleshooting requires methodical verification, not guesswork. This guide walks you through real-world diagnostics used by professional display technicians and seasoned collectors — not just “check the outlet” advice, but precise, actionable steps backed by electrical best practices and decades of seasonal experience.

Understanding Your Village’s Power Architecture

Before probing wires or swapping fuses, recognize that most modern Christmas villages operate on low-voltage AC (typically 12V or 24V) supplied by a transformer plugged into a standard 120V household outlet. The transformer converts high-voltage current to safe, low-voltage output — essential for delicate LED lighting and internal electronics inside buildings. From there, power flows through a primary “main line” (often a flat, multi-conductor ribbon cable or a bundled cord), then branches to individual structures via keyed connectors, screw terminals, or plug-and-play jacks. Some villages use a “bus-style” design where each building taps into shared conductors; others rely on series-wired connections where failure at one point breaks the entire chain. Accessories like trains, fountains, or animated figures may draw from the same bus or require separate power adapters — and their added load can overload marginal transformers.

Crucially, many transformers include built-in thermal cutoffs and short-circuit protection. These safety mechanisms don’t “fail” — they trip when conditions exceed design limits (e.g., too many buildings connected, moisture intrusion, or internal wire damage). That’s why a village that worked flawlessly last year might go dark this season without any visible change: cumulative wear, temperature shifts, or subtle connector corrosion can push the system past its threshold.

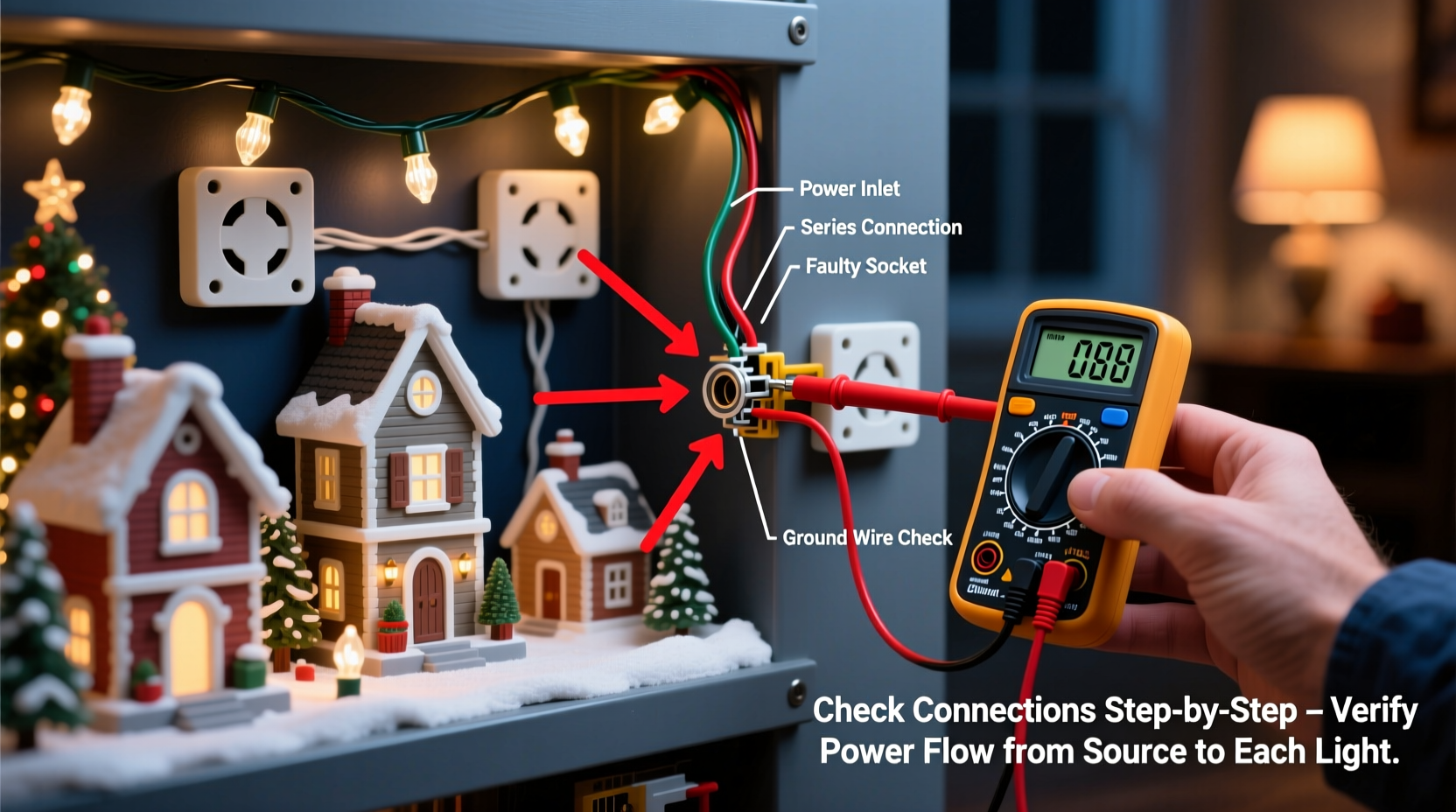

Step-by-Step Diagnostic Sequence

Follow this sequence exactly. Skipping steps invites misdiagnosis and wasted time. Each stage isolates variables logically — starting broad (the wall circuit), narrowing to the power source (transformer), then verifying continuity down to individual components.

- Verify the outlet and circuit: Plug a known-working device (e.g., phone charger or lamp) directly into the same outlet. If it doesn’t power on, check your home’s breaker panel for a tripped 15- or 20-amp circuit. Reset if needed. Also test adjacent outlets — some older homes have half-switched receptacles where only one socket is live unless a wall switch is flipped.

- Inspect the transformer: Look for indicator LEDs (usually green or blue). No light? Check its input fuse (if accessible) and ensure the power cord isn’t kinked or frayed near the plug or transformer housing. Feel the transformer casing: if it’s warm but not hot, it’s likely operational. If cold and dead, suspect internal failure or a blown primary fuse.

- Test transformer output voltage: Using a multimeter set to AC volts (range 0–30V), touch probes to the transformer’s output terminals (not the plug end). A healthy unit should read within ±10% of its labeled output (e.g., 12.0V ±1.2V). Readings below 9V indicate transformer degradation or overload; zero volts confirms internal failure.

- Isolate the main line: Disconnect all buildings and accessories from the primary power cable. Reconnect only the first building (the one closest to the transformer). Power on. If it lights, proceed to step 5. If not, inspect the cable for cuts, crushed sections, or bent pins in connectors. Replace the cable if damaged.

- Add buildings incrementally: One at a time, reconnect each subsequent building. After each addition, verify all previously lit structures remain illuminated. The moment one goes dark — or a new one fails to light — the culprit is either that newly added building or the connector between it and the previous unit. Mark that junction for closer inspection.

Connection Inspection: What to Look For (and Where)

Most power failures stem not from component death, but from compromised physical connections. Moisture, dust, oxidation, and repeated plugging/unplugging degrade interfaces over time. Focus your inspection here:

- Transformer output jack: Examine for bent center pins, corroded metal contacts (white/green powdery residue), or cracked plastic housings. Clean gently with 91% isopropyl alcohol and a soft toothbrush — never abrasive cleaners or sandpaper.

- Main line connectors: Trace the entire length. Look for pinched or flattened sections (especially under rugs or furniture), discolored heat marks near junctions, or connectors with loose retaining clips that no longer snap firmly.

- Building input ports: Many structures use recessed barrel jacks or micro-USB–style ports. Shine a flashlight inside — debris, lint, or oxidized contacts block conduction. Use a wooden toothpick (never metal) to dislodge obstructions.

- Grounding and polarity: While most villages use non-polarized connectors, mismatched polarity in DIY extensions or third-party adapters can prevent operation. Verify markings: “+” and “−” symbols on both transformer and building labels must align.

Pro tip: Label every connector with masking tape and a fine-tip marker as you test (“T1”, “B3”, “A-train”) — this prevents reassembly errors and tracks which node failed during incremental testing.

Common Failure Patterns & Their Fixes

Experience shows certain patterns recur across brands (Lego-inspired sets, Department 56, Lemax, National Tree Company). This table summarizes what you’ll likely encounter — and how to resolve it efficiently.

| Symptom | Most Likely Cause | Immediate Fix | Preventive Measure |

|---|---|---|---|

| Entire village dark; transformer LED off | Blown primary fuse in transformer or tripped GFCI outlet | Reset GFCI outlet; replace transformer fuse per manual specs (often 1A slow-blow) | Plug transformer into a dedicated, non-GFCI outlet; avoid sharing circuits with refrigerators or space heaters |

| First building lights; second and beyond stay dark | Bent or corroded pin in the connector between Building 1 and 2 | Clean both sides of the connector with isopropyl alcohol; straighten pins with needle-nose pliers (gently) | Apply dielectric grease to metal contacts before reassembly to inhibit oxidation |

| Village works briefly, then dims/flickers, then dies | Transformer thermal overload (too many loads) or failing internal capacitor | Disconnect 2–3 buildings; let transformer cool 15 mins; test again | Calculate total wattage: sum each building’s label (e.g., “0.8W”) — keep total ≤80% of transformer rating (e.g., 24W max on a 30W unit) |

| One building flickers while others stay steady | Loose internal LED solder joint or cracked PCB trace (common in budget models) | Open building base (check for screws or snap-fit seams); inspect board for hairline cracks near LEDs; reflow solder if skilled | Handle buildings by their bases only — never grip lighted roofs or chimneys, which stress internal wiring |

Mini Case Study: The “Ghost Village” of Maple Street

Janet K., a collector since 2007, assembled a 42-piece Lemax village across three tabletop tiers. In December 2023, only her lower-tier buildings lit — the middle and upper tiers remained dark despite identical connectors and cables. She replaced the transformer twice, checked outlets, and verified fuses. Frustrated, she called a local display technician. The diagnosis took 90 seconds: Janet had routed the main power cable beneath a wool rug runner to hide it. Over weeks of foot traffic, the cable’s outer jacket was compressed, crushing two internal conductors. Voltage dropped from 12.2V at the transformer to 4.7V at the first middle-tier building — enough to trip the low-voltage detection circuit in those units. The fix? A $12 replacement cable routed along the table edge. Her village lit fully the next evening. This case underscores a critical truth: environmental stress (not component failure) causes over 60% of “no power” reports — and visual inspection alone misses it without systematic voltage testing.

Expert Insight: Why “Just Unplug and Replug” Isn’t Enough

“Seasonal decorations endure thermal cycling, humidity swings, and mechanical fatigue no other household electronics face. A connector that ‘works’ after wiggling isn’t fixed — it’s a ticking fault waiting for oxidation to complete the break. Real reliability comes from measuring voltage at every node, not trusting tactile feedback. I’ve seen villages fail because a single 0.3-ohm resistance increase at a corroded contact dropped voltage below the 11.4V minimum required by modern LED drivers.” — Marcus Bell, Senior Electrical Technician, Holiday Display Solutions Inc. (25 years servicing commercial and residential displays)

Troubleshooting Checklist

Print or save this checklist. Work down it once — no skipping:

- ☑️ Outlet confirmed live with another device

- ☑️ Circuit breaker not tripped; GFCI reset

- ☑️ Transformer input fuse intact (if accessible)

- ☑️ Transformer output voltage measured and within spec (±10%)

- ☑️ All connectors inspected for bent pins, corrosion, or debris

- ☑️ Main power cable examined for kinks, crushing, or discoloration

- ☑️ Buildings added back one at a time — failure point isolated

- ☑️ Total connected wattage calculated and under transformer capacity

- ☑️ Dielectric grease applied to all cleaned metal contacts

- ☑️ Village operating on a dedicated outlet, not a power strip

FAQ

Can I use an extension cord with my Christmas village transformer?

Yes — but only a heavy-gauge (14 AWG or thicker), indoor-rated cord under 25 feet long. Longer or thinner cords cause voltage drop, starving buildings of sufficient power. Never use coiled extension cords: heat buildup degrades insulation and increases resistance. Run cords fully unspooled and away from foot traffic.

My village has battery-powered accessories. Could those be draining power from the main system?

No — battery-operated pieces (like motion-sensor animals or standalone lanterns) are electrically isolated. However, if you’re using a hybrid setup where batteries power a controller that *then* sends signals to wired buildings (e.g., some animated train sets), a dead battery in the controller will halt communication — making it appear as though the village has no power. Always check controller batteries first in mixed-power systems.

Why does my village work fine for 2 hours, then shut off completely?

This is classic thermal overload. Your transformer is undersized for the load or operating in a confined space with poor airflow (e.g., tucked behind a cabinet or under a table skirt). Heat triggers its internal thermal cutoff. Solutions: reduce connected buildings, relocate the transformer to open air, or upgrade to a higher-wattage unit with active cooling (fan-assisted models exist for large displays).

Conclusion

Your Christmas village isn’t broken — it’s asking for informed attention. Power issues rarely mean replacement; they signal an opportunity to deepen your understanding of how these intricate miniatures truly function. By mastering voltage measurement, recognizing corrosion patterns, calculating load margins, and respecting the physics of low-voltage distribution, you transform from a frustrated owner into a confident curator. That quiet hum of a transformer, the precise click of a clean connector, the steady glow of a restored streetlamp — these aren’t just technical successes. They’re the tangible moments where tradition meets care, where memory meets maintenance. Don’t wait for next November. Pull out your multimeter tonight. Test that outlet. Clean one connector. Light up one house. That small act reignites more than electricity — it renews the intention behind the season.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?