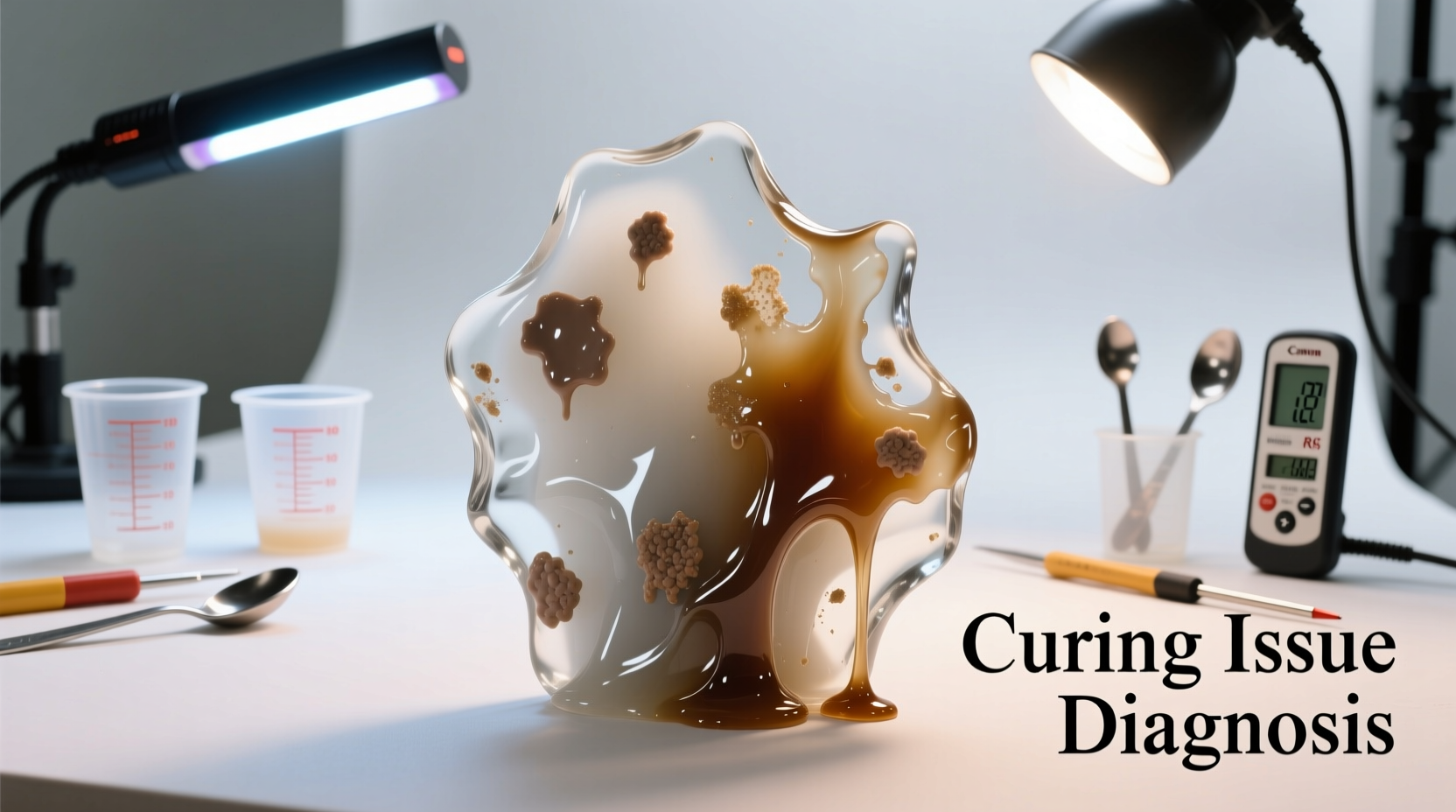

Resin art offers a mesmerizing blend of depth, clarity, and color that captivates artists and collectors alike. But nothing is more frustrating than finishing a piece only to find it still tacky days later. A sticky surface not only ruins the visual appeal but can also compromise durability and safety. While epoxy resin is designed to cure into a hard, glass-like finish, various factors can interfere with this process. Understanding why your resin remains sticky—and how to prevent or fix it—is essential for consistent, professional-quality results.

Understanding How Resin Cures

Epoxy resin cures through a chemical reaction between the resin and hardener components. This exothermic process generates heat and transforms the liquid mixture into a solid state. Unlike drying (as with water-based paints), curing does not rely on evaporation—it depends entirely on proper chemical bonding. If this reaction doesn’t complete fully, the resin remains soft, sticky, or greasy to the touch.

The ideal cure requires three key elements: precise mixing ratios, adequate temperature, and sufficient time. Deviations in any of these areas can lead to incomplete polymerization—the scientific term for the chain reaction that forms durable plastic networks. When polymerization stalls, residual uncured monomers remain on the surface, causing stickiness.

“Resin doesn’t dry; it cures. That means environmental conditions and accurate measurement are non-negotiable.” — Dr. Lena Torres, Polymer Chemist & Materials Consultant

Common Causes of Sticky Resin

Several variables can disrupt the curing process. Identifying the root cause is the first step toward resolution.

Incorrect Mixing Ratio

Most resins require a specific ratio—commonly 1:1 or 2:1 (resin to hardener). Even slight deviations prevent full cross-linking of molecules. Too much resin leaves unreacted components; too much hardener accelerates the reaction but may leave behind excess amine compounds that never bind.

Incomplete Mixing

Stirring too briefly or unevenly leads to pockets of unmixed resin or hardener. These zones fail to initiate or sustain the curing reaction. Always mix slowly and thoroughly for at least 3–5 minutes, scraping the sides and bottom of the container to ensure homogeneity.

Low Ambient Temperature

Colder environments slow down molecular activity, delaying or halting the chemical reaction. Most standard epoxy resins perform best between 72°F and 77°F (22°C–25°C). Below 65°F (18°C), curing becomes significantly impaired.

High Humidity

Excess moisture in the air can interfere with surface curing, leading to a sticky film known as \"amine blush.\" This waxy layer forms when moisture reacts with amines in the hardener. It often appears cloudy and feels slightly tacky, even if the bulk of the resin has hardened.

Expired or Poor-Quality Materials

Old resin or hardener loses potency over time, especially if stored improperly. UV exposure, extreme temperatures, or contamination from prior use degrade components. Likewise, low-cost resins may lack reliable formulations, increasing failure risk.

Troubleshooting Sticky Resin: A Step-by-Step Guide

If your resin project remains sticky after the expected cure time (typically 24–72 hours), follow this systematic approach to diagnose and resolve the issue.

- Assess the Stickiness Level: Light tackiness may indicate surface inhibition due to oxygen or humidity. Full stickiness throughout suggests a deeper curing failure.

- Check Environmental Conditions: Verify room temperature and humidity during pouring and curing. Use a digital hygrometer if possible.

- Review Mixing Procedure: Confirm whether you measured accurately using graduated cups and mixed long enough. Did you scrape the container walls?

- Inspect for Amine Blush: Wipe a small area with isopropyl alcohol (IPA) on a lint-free cloth. If residue transfers, it’s likely amine blush rather than uncured resin.

- Determine Cure Stage: Press a toothpick gently into the surface. If it sinks in, the resin hasn't cured. If it leaves a dent but doesn’t penetrate, partial cure occurred.

Immediate Actions Based on Diagnosis

- For Surface Tack (Amine Blush): Clean with 90%+ isopropyl alcohol and a microfiber cloth. Allow to dry completely. Once clean, apply a fresh, thin top coat of properly mixed resin to seal the surface.

- For Partial Cure Due to Cold Temperatures: Move the piece to a warmer environment (ideally 75°F/24°C). Gently warm the surface with a hairdryer on low heat, keeping it 6–8 inches away. Avoid overheating, which can cause bubbling.

- For Complete Failure (Gooey or Soft): Unfortunately, recoating won’t fix deeply uncured layers. You must remove the failed resin before proceeding.

How to Remove and Re-Cure Failed Resin

When resin fails to cure entirely, removal is necessary before reapplying. Here’s how to do it safely and effectively.

Option 1: Sanding Off Uncured Resin

Wear gloves, eye protection, and a respirator. Use coarse-grit sandpaper (80–120 grit) to grind down the sticky layer until reaching a firm base. Wipe dust with IPA, then apply a new coat following correct procedures.

Option 2: Solvent Wipe (Limited Effectiveness)

Apply acetone or lacquer thinner sparingly with a cloth to dissolve soft resin. This method works only for thin, uncured films and should be done in a well-ventilated area. Rinse afterward with IPA to remove solvent residue.

Option 3: Controlled Heat Removal

Using a heat gun on low setting, soften the resin until it lifts easily with a plastic scraper. Be cautious—overheating emits toxic fumes and damages substrates like wood or canvas.

Prevention Checklist: Ensuring Flawless Cures Every Time

Consistency in technique and environment dramatically reduces the risk of sticky resin. Follow this checklist before every pour:

- ✔️ Measure resin and hardener precisely using calibrated dispensers or digital scales

- ✔️ Mix for a minimum of 3 minutes, ensuring full incorporation from container edges and bottom

- ✔️ Work in a space maintained at 72–77°F (22–25°C) with humidity below 50%

- ✔️ Pre-warm cold resin bottles by placing them in warm water (not exceeding 100°F/38°C)

- ✔️ Allow adequate cure time—do not disturb pieces for at least 24 hours

- ✔️ Cover projects with a dust cover (e.g., cardboard box) to minimize airborne contaminants

- ✔️ Test a small batch first when trying new pigments, additives, or molds

| Do’s | Don’ts |

|---|---|

| Use dedicated mixing tools for each component | Reuse sticks or cups between batches without cleaning |

| Stir slowly to reduce bubble formation | Mix too quickly, whipping in excessive air |

| Cure in a stable, climate-controlled room | Place near windows, vents, or heaters causing drafts |

| Allow 5–7 days for full hardness development | Handle or hang artwork within 48 hours of pouring |

| Store unused resin upright in a cool, dark cabinet | Leave lids off or store in garages with temperature swings |

Real Example: A Jewelry Maker’s Fix

Sophie, an artisan creating resin pendants, repeatedly encountered sticky backs on her pieces despite following instructions. After ruling out expired materials, she realized her studio dropped to 60°F overnight. She began pre-warming her resin bottles in a temperature-stable water bath and used a small space heater to maintain 73°F during curing. She also switched to a slow-cure, high-clarity jewelry resin formulated for cooler conditions. Within two weeks, all her pieces cured perfectly—hard, glossy, and ready for polishing.

This case highlights how subtle environmental shifts can derail results—even when technique seems flawless.

Frequently Asked Questions

Can I speed up curing with a heat gun or UV light?

Heat guns can help in mild cases of slow curing but should be used cautiously—excessive heat causes cracks or bubbles. UV light does not accelerate standard epoxy resin curing, as most are chemically (not UV) activated. Only UV-resin types respond to light exposure.

Why did only the edges stay sticky?

Edge tackiness often occurs because thin areas lose heat faster than thick pours, slowing the reaction. Additionally, oxygen inhibition prevents surface skinning. This can usually be resolved with a light sanding and a final top coat.

Is sticky resin dangerous?

Uncured resin contains reactive chemicals that can irritate skin and respiratory systems. Avoid direct contact and work in ventilated areas. Fully cured resin is inert and safe to handle. Never seal sticky resin under doming or framing—it may continue off-gassing and degrade surrounding materials.

Expert Tips for Long-Term Success

Professional resin artists emphasize consistency and control. One common oversight is failing to acclimate materials before use. Bringing cold resin directly from storage into a warm room creates condensation inside the bottle, introducing moisture that sabotages the reaction.

“Let your resin sit in the workspace for 12–24 hours before use. Equalize temperature and eliminate moisture risk.” — Marcus Reed, Fine Art Resin Instructor

Another pro tip: invest in a dual-component dispensing pump system if you work frequently with the same brand. Pumps ensure repeatable ratios far more accurately than manual pouring.

Finally, document your process. Keep a log of ambient temperature, mix times, and cure outcomes. Over time, patterns emerge that help refine your workflow and anticipate issues before they arise.

Conclusion: Turn Sticky Setbacks into Smooth Success

Sticky resin doesn’t mean failure—it’s feedback. Each challenge reveals insights about your process, environment, and materials. By understanding the science behind curing and applying disciplined practices, you can consistently achieve crystal-clear, hard-as-glass finishes. Whether you're crafting coasters, river tables, or intricate jewelry, precision and patience are your greatest tools.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?