A washing machine should hum quietly through its cycle, not rattle, clunk, or grind like a construction site. If you're hearing metallic scraping, low rumbling, or sharp grinding noises during operation, it’s more than just an annoyance—it's a warning sign. These sounds often point to mechanical issues that, if ignored, can lead to costly repairs or even total appliance failure. Understanding the root causes and knowing when to act can save time, money, and prevent further damage.

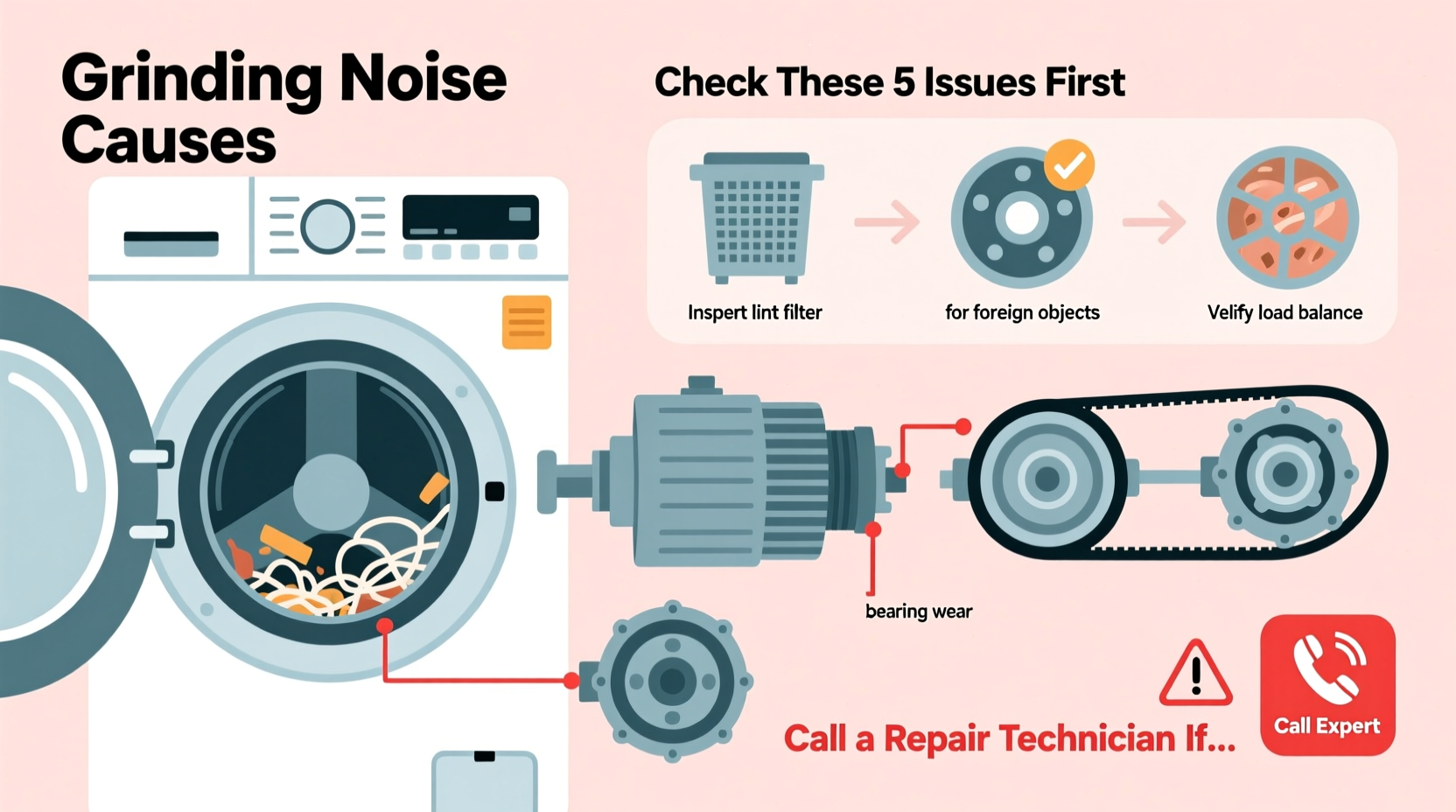

Common Causes of Grinding Noises in Washing Machines

Grinding noises typically stem from internal components under stress or failing due to wear. While modern machines are built for durability, regular use takes a toll. Here are the most frequent culprits behind the unsettling sounds:

- Failing drum bearings: Bearings support the drum’s rotation. When they wear out—often due to water leakage into the bearing seal—they produce a loud grinding or rumbling noise, especially during the spin cycle.

- Foreign objects trapped in the pump or drum: Coins, buttons, hairpins, or small toys can slip past the drum and get lodged between moving parts, causing scraping or grinding with each rotation.

- Worn or damaged drive pulley: The pulley connects the motor to the drum via a belt. If cracked or misaligned, it may create a rhythmic grinding or squealing sound.

- Defective motor brushes (in older models): In brushed motors, carbon brushes wear down over time. When they degrade, they can cause a grinding or buzzing noise as the motor struggles to turn.

- Damaged shock absorbers or suspension rods: These dampen drum movement. If broken, the drum can shift violently, hitting the cabinet and creating metallic thuds or grinding during spin.

- Loose counterweights: Many machines have heavy concrete or metal blocks to stabilize the drum. If mounting bolts loosen, the weights can shift and rub against other parts.

How to Diagnose the Source of the Noise

Pinpointing the exact cause requires careful observation and methodical testing. Start by identifying when the noise occurs—during fill, wash, drain, or spin—as this narrows down the suspect components.

- Listen closely to the noise pattern: Is it continuous, intermittent, or only during high-speed spin? A grinding sound that worsens at higher RPMs often indicates bearing or balance issues.

- Run an empty cycle: Remove all laundry and run a standard wash. If the noise persists, it’s likely mechanical, not caused by items in the load.

- Check the drain pump filter: Located behind a small access panel near the bottom front, this filter traps debris. Open it (after placing a towel to catch water) and remove any foreign objects.

- Inspect beneath the machine: Tilt the washer slightly (with help) to look underneath for loose parts, damaged belts, or oil residue—which suggests a failed tub seal and leaking bearings.

- Manually rotate the drum: With the machine off, turn the drum by hand. If you feel resistance, grinding, or wobbling, the bearings or suspension system may be compromised.

When the Problem Isn’t Obvious

Sometimes, internal components aren't accessible without disassembly. For example, rear drum bearings require removing the back panel and possibly the drum itself—a task beyond most DIYers. In such cases, documenting the noise (audio or video) can help a technician make a faster diagnosis.

“Over 60% of grinding noise service calls we handle involve failed drum bearings or foreign objects in the pump. Early detection prevents secondary damage to the motor or tub.” — Carlos Mendez, Senior Appliance Technician, HomeFix Solutions

Do’s and Don’ts: What to Avoid When Your Washer Grinds

| Action | Do | Don’t |

|---|---|---|

| Upon hearing noise | Stop the cycle immediately and unplug the unit. | Continue using the machine hoping the sound will go away. |

| Cleaning | Clear the drain filter and check for visible obstructions. | Use harsh chemicals or pressure washers on internal parts. |

| DIY inspection | Check accessible areas like the detergent drawer and filter. | Disassemble sealed compartments without proper tools or knowledge. |

| Repairs | Contact a certified technician for internal issues. | Attempt to replace bearings or seals without experience. |

| Prevention | Use mesh laundry bags for small items and avoid overloading. | Wash shoes, zippers, or metal-trimmed clothing without protection. |

Real-World Example: A Costly Delay in Repairs

Sarah from Portland noticed a faint grinding sound during her washer’s spin cycle but dismissed it as “just getting old.” She continued using the machine for six weeks, occasionally tightening a loose hose she thought was the issue. Eventually, the noise turned into a loud roar, and the drum began wobbling violently. By the time she called a technician, the drum bearings had completely failed, water had seeped into the outer tub, and rust was spreading. The repair required replacing the drum, bearings, and seal—a job that cost nearly 70% of a new machine’s price.

This case illustrates how ignoring early symptoms escalates minor issues into major failures. Had Sarah addressed the noise within the first week, a simple filter cleaning or professional inspection might have prevented thousands in unnecessary expenses.

Step-by-Step Guide: What to Do When You Hear Grinding

Follow this timeline to respond effectively and safely:

- Day 1 – Stop and Assess: Halt the current cycle. Unplug the machine. Note when and how the noise occurs (e.g., only during spin, constant, etc.).

- Day 1 – Quick Inspection: Check the drain filter and detergent drawer. Remove any debris. Run an empty rinse cycle to confirm if the noise returns.

- Day 2 – Evaluate Load and Usage: Reflect on recent loads. Were bulky items like shoes or jeans washed? Could metal objects have slipped through?

- Day 3 – Manual Check: Gently rotate the drum. Listen for grinding or roughness. Look under the machine for leaks or loose parts.

- Day 4 – Decision Point:

- If the noise stops after cleaning the filter and no resistance is felt—monitor usage for one more cycle.

- If grinding persists or worsens—call a qualified repair technician.

- Within 7 Days – Professional Evaluation: Schedule a service visit. Delaying increases the risk of irreversible damage.

When to Call a Repair Technician

Some issues are manageable at home, but others demand professional expertise. Knowing when to pick up the phone can prevent further damage and ensure safety.

Call immediately if you notice:

- Grinding that intensifies during high-speed spins

- Visible smoke or burning smells from the motor area

- Oil or grease stains under the machine (indicates seal failure)

- The drum feels loose or wobbles excessively

- The machine fails to start or shuts off mid-cycle

Technicians have specialized tools to test motor windings, diagnose electronic control boards, and safely disassemble sealed units. Attempting these tasks without training can void warranties or create safety hazards.

Cost vs. Repair Dilemma

Consider repair costs relative to the machine’s age and value. As a rule of thumb:

- If the washer is under 5 years old and under warranty—always call for authorized service.

- If the repair estimate exceeds 50% of a comparable new model’s price—replacement may be more economical.

- If the machine has a history of recurring issues—evaluate long-term reliability.

Frequently Asked Questions

Can a grinding noise be caused by overloading?

Yes. Overloading shifts the drum’s balance, forcing components to work harder. This strain can mimic grinding, though it’s usually accompanied by shaking or walking across the floor. Redistribute the load evenly and avoid cramming too many items in one cycle.

Is it safe to continue using the washer if it’s making noise?

No. Continuing to operate a grinding washing machine risks damaging the motor, drum, or transmission. It may also cause leaks or electrical faults. Turn it off and investigate the cause promptly.

How much does it cost to fix a grinding washing machine?

Repairs vary widely. Simple fixes like clearing the pump filter are free. Bearing replacement ranges from $250 to $500, including labor. Motor or control board issues can exceed $600. Always request a diagnostic fee that’s credited toward repairs if you proceed.

Conclusion: Act Now, Save Later

A grinding washing machine isn’t just noisy—it’s signaling distress. Whether it’s a stray coin or failing bearings, the underlying issue won’t resolve itself. Early intervention preserves your appliance’s lifespan, prevents water damage, and avoids emergency breakdowns at inconvenient times. Use the checklist and guidance provided to assess your situation calmly and take appropriate action. If in doubt, consult a professional rather than risk worsening the problem.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?