A washing machine should operate with a steady hum, not loud banging or rhythmic thumping. If you're hearing knocking noises during the spin cycle—or at any point in the wash—something is off. These sounds don’t just disrupt peace; they can signal mechanical wear, improper use, or imminent failure. Ignoring them may lead to costly repairs or even appliance replacement. Understanding the root causes and knowing when to act can save time, money, and stress.

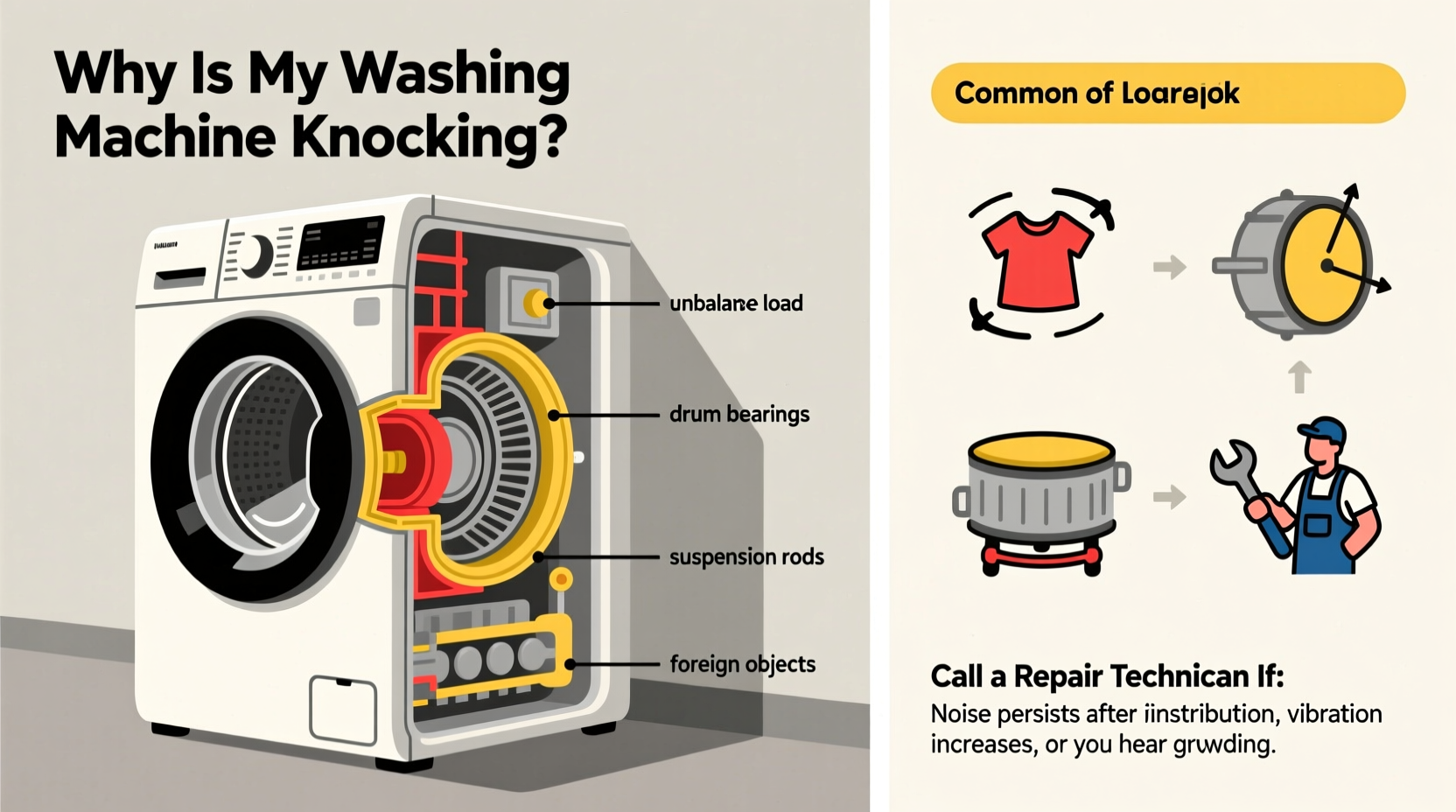

Common Causes of Knocking Noises in Washing Machines

Knocking sounds vary by timing and intensity, offering clues about what’s wrong. The issue might be as simple as an unbalanced load or as serious as a failing drum bearing. Below are the most frequent culprits behind abnormal washing machine noise.

1. Unbalanced Laundry Load

When clothes clump to one side of the drum during the spin cycle, the washer becomes unbalanced. This creates a rhythmic thumping that intensifies with speed. Front-loaders are especially prone due to their vertical drum orientation.

2. Foreign Objects Trapped in the Drum

Coin, keys, hairpins, or small toys can slip through pockets and get lodged between the inner and outer drum. As the machine spins, these objects strike the metal, producing sharp knocking or scraping sounds.

3. Worn or Damaged Shock Absorbers

Shock absorbers (or dampers) stabilize the drum during high-speed spins. Over time, they degrade, especially in machines used daily. When compromised, the drum moves excessively, causing heavy knocking against the cabinet.

4. Faulty Suspension Springs

Top-loading models often rely on springs to suspend the tub. If one breaks or weakens, the tub shifts unevenly, leading to metallic banging. You may also notice the entire machine \"walking\" across the floor.

5. Failing Drum Bearings

Bearings allow the drum to rotate smoothly. Once worn out—often from water leakage into the seal—they create grinding or knocking noises, particularly during spin. This is a serious mechanical issue requiring professional attention.

6. Loose or Damaged Counterweights

Washing machines have heavy concrete or metal counterweights bolted to the drum assembly to balance rotation. If bolts loosen or weights crack, violent vibrations and knocking occur.

7. Pump Obstruction or Failure

The drain pump removes water after each cycle. If debris jams the impeller, it may produce clicking or knocking during drainage. While less common than drum-related issues, a faulty pump shouldn't be overlooked.

Step-by-Step Guide to Diagnosing the Noise

Before calling a technician, perform a systematic check to identify the source. Follow this timeline to isolate the problem safely and effectively.

- Stop the Machine Immediately: If the noise is severe, halt the cycle to prevent further damage.

- Inspect the Load: Open the door and redistribute laundry. Run a short spin-only cycle to test if the noise returns.

- Check for Foreign Objects: Remove visible items from the drum. For front-loaders, inspect the rubber door gasket and drain filter.

- Run an Empty Cycle: Start a spin cycle without clothes. If knocking persists, the issue is mechanical.

- Observe the Timing: Note when the noise occurs:

- During fill? Likely not knocking—could be water hammer.

- During agitation? Possible suspension or motor mount issue.

- During spin only? Points to imbalance, shocks, bearings, or counterweights.

- Check Machine Movement: Does the washer shift or vibrate excessively? Test leveling and floor stability.

- Listen Closely: Use a mechanic’s stethoscope (or press a long screwdriver to your ear) near key components—shocks, base, rear panel—to pinpoint sound origin.

Do’s and Don’ts: Managing Washing Machine Noise

| Do’s | Don’ts |

|---|---|

| Redistribute laundry evenly before starting | Overload the machine beyond manufacturer capacity |

| Level the washer using adjustable feet | Ignore persistent noise after load adjustment |

| Clean the pump filter monthly | Use excessive detergent causing suds lock |

| Inspect shock absorbers for oil leaks or sagging | Attempt internal repairs without unplugging the unit |

| Schedule annual maintenance checks | Delay fixing known mechanical faults |

Real Example: When a Simple Fix Prevented Major Damage

Sarah, a homeowner in Portland, noticed her front-load Samsung washer making loud thuds during spin cycles. At first, she assumed it was normal vibration. After two weeks, the noise worsened, and the machine began shifting forward violently. She paused usage and ran an empty spin test. The knocking remained. Upon inspection, she found a child’s toy car wedged behind the drum, likely slipped through a pocket. Removing it eliminated the noise. But while cleaning, she also noticed one shock absorber was leaking fluid. She contacted a technician who confirmed both shocks needed replacement. By acting early, Sarah avoided drum misalignment and bearing damage—saving over $400 in potential repairs.

Expert Insight: What Technicians Want You to Know

“Knocking isn’t normal wear—it’s a warning sign. Early diagnosis of shock absorber or bearing failure can prevent catastrophic drum collapse.” — Mark Reynolds, Appliance Repair Specialist with 18 years of field experience

“Most service calls I handle could’ve been avoided. Homeowners wait until the noise becomes unbearable, but by then, secondary parts are damaged too.” — Lina Cho, Certified Whirlpool Technician

Checklist: When to Call a Repair Professional

Not every knocking noise requires immediate service. Use this checklist to determine urgency:

- ✅ Noise disappears after redistributing laundry → Monitor, no action needed.

- ✅ Object found and removed → Resume use cautiously.

- ❌ Noise continues on empty cycles → Investigate mechanically.

- ❌ Washer moves significantly during operation → Check leveling and flooring.

- ❌ Visible oil stains under the machine → Likely failed shock absorbers or seal leak.

- ❌ Grinding or rumbling accompanies knocking → Probable bearing failure.

- ❌ Machine won’t spin or displays error codes → Electrical or control board issue.

- ❌ Loud banging even at low speeds → Internal component detachment.

- ❌ Recent water leak history → High risk of corrosion or seal damage.

If three or more “❌” items apply, professional assessment is strongly recommended.

How Long Can You Safely Delay Repairs?

Minor imbalances can be managed temporarily. However, mechanical faults deteriorate rapidly. Here’s a realistic timeline:

- Day 1–3: Occasional knock during spin. Try load redistribution and empty test.

- Day 4–7: Noise persists. Inspect for foreign objects and leveling. If unresolved, schedule a diagnostic call.

- Week 2: Increased volume or new symptoms (vibration, movement). Continued use risks motor, drum, or housing damage.

- After Week 2: Risk of total breakdown rises sharply. Bearing failure can seize the drum, rendering the machine unusable.

Delaying beyond ten days on confirmed mechanical issues often doubles repair costs due to collateral damage.

Cost Implications of DIY vs. Professional Service

Some online guides suggest replacing shocks or bearings yourself. While possible, it’s labor-intensive and risky without proper tools. Consider the trade-offs:

| Repair Type | DIY Cost (Parts Only) | Professional Cost | Time Required | Risk Level |

|---|---|---|---|---|

| Shock Absorbers (Pair) | $40–$70 | $180–$300 | 2–3 hours | Moderate |

| Drum Bearings | $60–$100 | $400–$600 | 4–6 hours | High |

| Pump Replacement | $30–$50 | $150–$250 | 1–2 hours | Low |

| Counterweight Reattachment | $0 (if intact) | $100–$200 | 1 hour | Low-Moderate |

Note: DIY attempts without experience often result in misalignment, electrical shorts, or voided warranties. Unless you’re technically skilled, professional service is safer and more reliable.

FAQ: Common Questions About Washing Machine Knocking

Is it safe to use a washing machine that makes knocking noises?

Occasional light thumping due to imbalance is generally safe for one or two cycles. Persistent or loud knocking, especially during spin, indicates mechanical stress. Continued use risks damaging the drum, motor, or seals. It’s best to stop operation and investigate.

Can overloading cause knocking sounds?

Yes. Overloading prevents even distribution of clothes, leading to imbalance. It also strains the motor, suspension, and bearings. Always follow the manufacturer’s load guidelines—typically ¾ full for top-loaders, ½ to ⅔ for front-loaders.

Why does my washer knock only during the spin cycle?

The spin cycle generates centrifugal force, amplifying any imbalance or mechanical flaw. Components like shocks, springs, and bearings endure maximum stress here. If noise is exclusive to spinning, focus diagnostics on these systems.

Conclusion: Act Now to Protect Your Appliance and Budget

A knocking washing machine isn’t just noisy—it’s communicating distress. Whether the cause is user error or mechanical failure, timely response prevents minor issues from becoming major expenses. Simple habits like checking pockets, leveling the unit, and avoiding overloading go a long way. When in doubt, trust your ears. If the sound feels wrong, it probably is.

Don’t wait for complete breakdown. Address unusual noises early with methodical checks, and involve a qualified technician when signs point to internal damage. Your washing machine works hard for you; return the favor with proactive care.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?