When designing electronic circuits, especially those involving power regulation, filtering, or signal conditioning, selecting the right ceramic capacitor is critical. Among the most commonly used types are X7R and X5R dielectrics. While both belong to the Class II ceramic capacitor family and offer high volumetric efficiency, their performance diverges significantly under varying conditions—especially temperature. Understanding these differences ensures your circuit remains stable, reliable, and cost-effective over its operational life.

The confusion between X7R and X5R often stems from their similar naming conventions and overlapping use cases. However, subtle but important distinctions in temperature range, capacitance stability, and aging behavior can make one far more suitable than the other depending on your application’s environment and precision requirements.

Understanding Ceramic Capacitor Classifications

Ceramic capacitors are categorized by their dielectric material, which determines electrical characteristics such as capacitance stability, voltage coefficient, and temperature response. The Electronic Industries Alliance (EIA) established a standardized coding system—like X7R and X5R—to define these parameters.

The three-character code breaks down as follows:

- First character: Minimum operating temperature (in °C)

- Second character: Maximum operating temperature (in °C)

- Third and fourth characters: Maximum allowable capacitance change over that temperature range

For example:

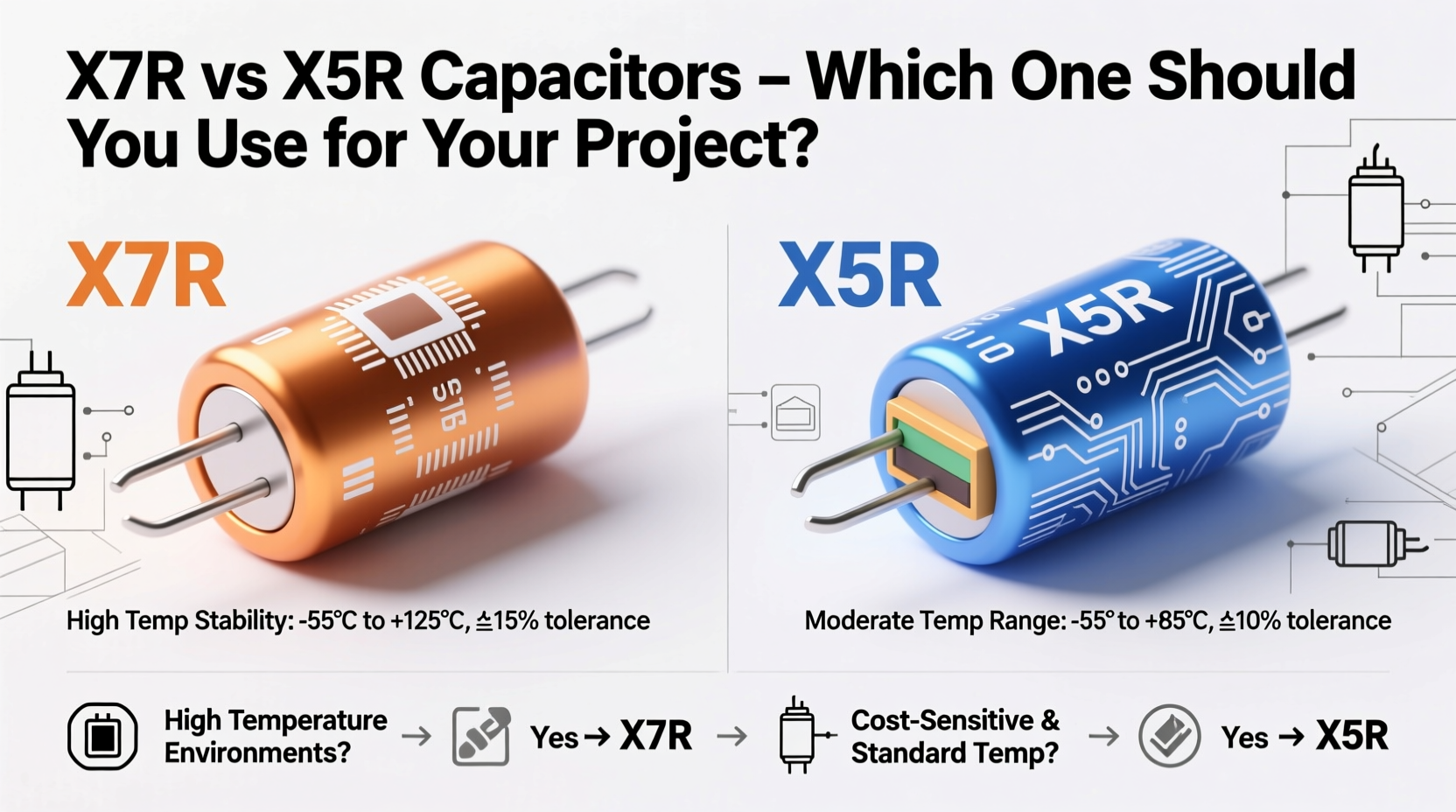

| Code | Min Temp | Max Temp | Capacitance Change |

|---|---|---|---|

| X7R | -55°C | +125°C | ±15% |

| X5R | -55°C | +85°C | ±15% |

This means an X7R capacitor maintains its rated capacitance within ±15% across a wider temperature range compared to X5R, which is only guaranteed up to +85°C. This single difference has major implications for industrial, automotive, and outdoor electronics.

Performance Comparison: Stability and Drift

Both X7R and X5R capacitors exhibit nonlinear behavior with respect to temperature and applied DC bias. As voltage increases across the capacitor, effective capacitance decreases due to ferroelectric domain saturation in the dielectric. This effect is more pronounced in smaller case sizes (e.g., 0402, 0603).

However, when comparing temperature-induced drift:

- X7R: Stable from -55°C to +125°C with ≤±15% variation. Ideal for environments subject to wide thermal swings.

- X5R: Same ±15% tolerance but limited to +85°C max. Beyond this point, capacitance can drop sharply, potentially causing circuit malfunction.

In real-world applications, consider a DC-DC converter on a vehicle’s engine control unit. Under hood temperatures regularly exceed 100°C during operation. An X5R capacitor might lose well beyond 15% of its nominal value, risking instability in feedback loops or inadequate output filtering. In contrast, X7R would remain within specification.

“Don’t assume datasheet ratings reflect real-world performance. A capacitor rated at 10µF may behave like 6µF under combined thermal and DC bias stress.” — Rajiv Mehta, Senior Analog Design Engineer at Infineon Technologies

Application Guidelines: Where Each Type Shines

Choosing between X7R and X5R isn't just about specifications—it's about matching component behavior to system demands.

Best Uses for X7R Capacitors

- Automotive electronics (ECUs, sensors, infotainment systems)

- Industrial controls exposed to high ambient temperatures

- Power supply bulk decoupling near hot components (e.g., MOSFETs, regulators)

- Outdoor or uncontrolled environmental deployments

Best Uses for X5R Capacitors

- Consumer electronics operating indoors (smartphones, routers, wearables)

- Low-power IoT devices with passive cooling

- Budget-sensitive designs where extended temperature range isn’t required

- General-purpose bypassing in office-temperature environments

While X5R offers slightly lower cost and marginally better volumetric efficiency in some cases, it should never be used in any application expecting sustained operation above 85°C—even if brief.

Mini Case Study: Failed Voltage Regulator in Solar Inverter

A solar microinverter manufacturer experienced intermittent failures in field units after six months of operation. Investigation revealed that the output filter capacitors—specified as 10µF X5R in 0805 package—were losing over 40% of their capacitance under full load.

Root cause analysis showed that while ambient temperature was around 40°C, the nearby switching transformer heated the local board area to 95°C. Since X5R is not rated for this temperature, the dielectric response degraded rapidly. Replacing the capacitors with X7R equivalents resolved the issue without redesigning the entire layout.

This case highlights how overlooking localized thermal effects can lead to premature product failure—even when following standard design practices.

Step-by-Step Guide to Selecting the Right Dielectric

Follow this process to confidently choose between X7R and X5R for your next project:

- Determine maximum operating temperature – Include both ambient and self-heating effects from nearby components.

- Evaluate capacitance sensitivity – Ask: Will a 15–30% drop in capacitance affect functionality? (e.g., in timing circuits or filters?)

- Analyze DC bias impact – Use manufacturer tools (like K-SIM from Kemet or SimSurfing from Murata) to estimate real capacitance under voltage.

- Check lifetime and aging – Both types age at ~2.5% per decade hour, but higher temps accelerate this. Consider derating accordingly.

- Compare availability and cost – For non-critical, low-temp applications, X5R may save cents per unit; weigh against risk of field failure.

Checklist: Final Selection Criteria

Before finalizing your BOM, confirm the following:

- ☑ Operating temperature stays below +85°C? → X5R acceptable

- ☑ Temperature exceeds +85°C even briefly? → Use X7R

- ☑ Located near heat sources (processors, power stages)? → Prefer X7R

- ☑ Used in safety-critical or long-life product? → Choose X7R

- ☑ Cost-sensitive consumer device with controlled environment? → X5R viable

- ☑ High DC bias (>50% rated voltage)? → Verify actual capacitance via simulation

Frequently Asked Questions

Can I replace X5R with X7R in an existing design?

Yes, in nearly all cases. X7R capacitors have equal or better electrical characteristics and are drop-in compatible in terms of footprint and rating. The reverse (replacing X7R with X5R) is risky and not recommended for high-temperature environments.

Do X7R and X5R capacitors age differently?

No. Both use barium titanate-based dielectrics and exhibit similar aging rates—approximately 2.5% loss of capacitance per decade hour after reflow. This aging is reversible through heating above the Curie temperature (e.g., during soldering), which resets the clock.

Is there a significant price difference?

Typically, X7R costs 10–20% more than X5R for equivalent values and packages. However, this gap narrows at scale, and the added reliability often offsets potential warranty or repair costs.

Conclusion: Making the Right Choice for Long-Term Success

Selecting between X7R and X5R capacitors goes beyond reading a datasheet—it requires understanding your product’s operational reality. While X5R remains a valid choice for cost-driven, indoor-use electronics, X7R provides essential headroom for thermal and electrical stresses common in modern designs.

As electronics continue to shrink and pack more power into tighter spaces, passive components must keep pace. Choosing X7R doesn’t just future-proof your design—it prevents silent failures that stem from overlooked environmental factors.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?