All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

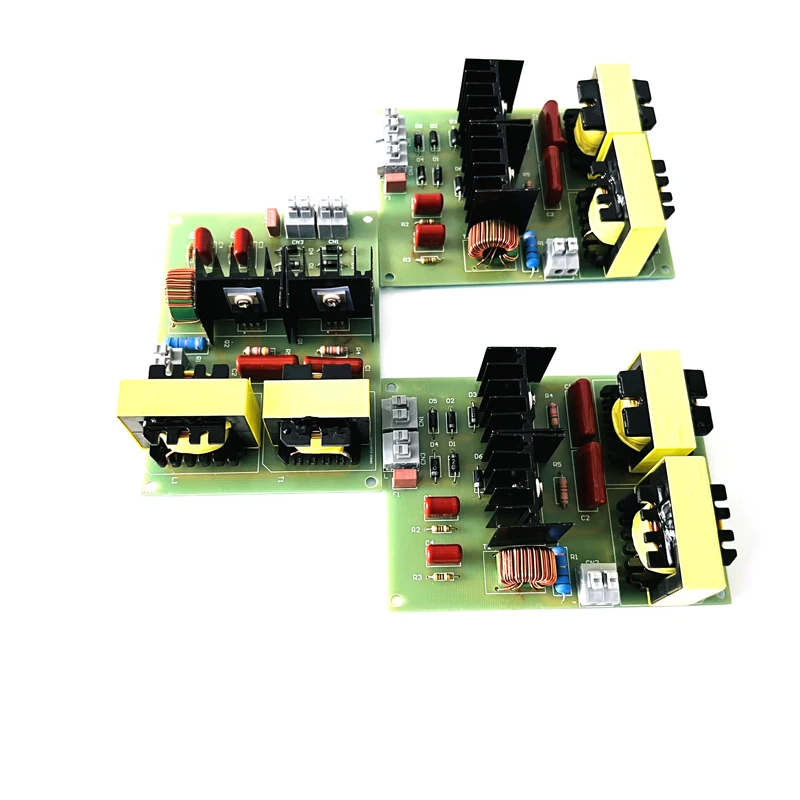

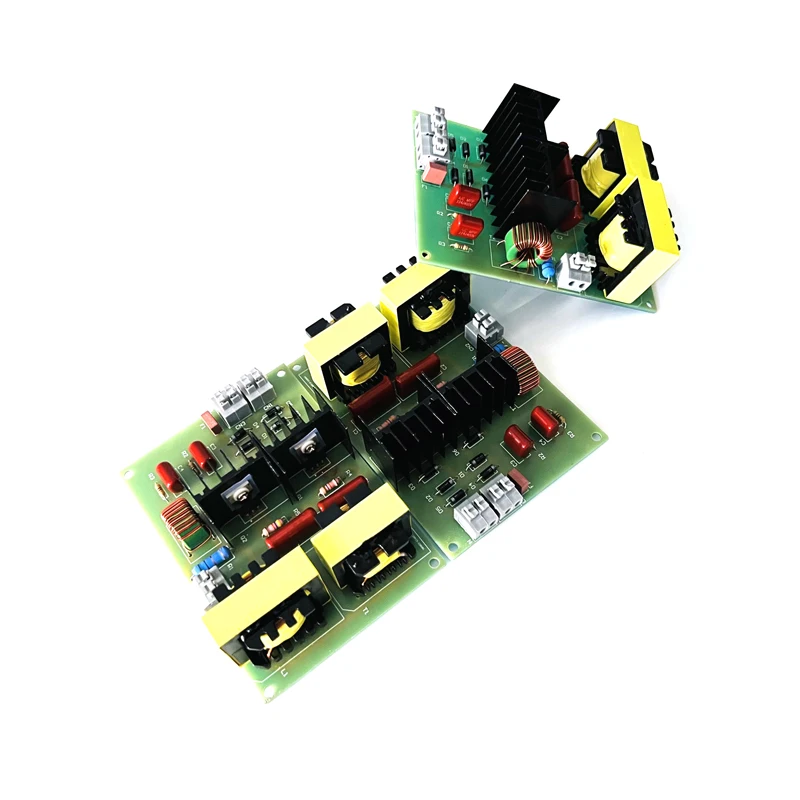

With FR-4 PCB material, ensure durability and stability under high power loads, outperforming standard PCBs*.

With a modular design, customize components to suit specific cleaning applications, adapting to diverse industrial or commercial needs.

With 40kHz frequency and 150W output, achieve ~20% faster cleaning cycles than standard 28kHz models*.

Designed for commercial use, handle continuous operation without performance degradation, ideal for heavy-duty cleaning tasks like industrial parts or automotive components.

With EPR certifications from France and Germany, meet stringent environmental regulations for packaging waste in Europe, ensuring compliance with eco-friendly standards.

The 28KHz/40KHz 150W Ultrasonic Generator Circuit Board is a high-performance control PCB designed for heated sweep ultrasonic vibration cleaner machines. Built with modular components like power transformers, capacitors, and semiconductors, it delivers robust power handling and reliability for industrial, automotive, and laboratory applications. Certified to EPR standards in France and Germany, it ensures compliance with environmental regulations while enabling precise frequency control and energy efficiency.

| Feature | Specification | Benefit |

|---|---|---|

| Frequency Range | 28kHz to 40kHz adjustable | Flexible cleaning power for diverse tasks |

| Power Output | 150W nominal | Sustained performance in high-demand environments |

| Certifications | EPR_France_Packing, EPR_Germany_Packing | Regulatory compliance and eco-friendly design |

| Material | FR-4 epoxy glass PCB | Enhanced thermal and mechanical stability |

| Components | High-capacity capacitors, power transformers | Reliable energy storage and voltage regulation |

Adjustable frequency settings (28kHz–40kHz) and modular component slots allow customization for specific applications. For example:

Maximize efficiency in precision cleaning with this ultrasonic PCB. Ideal for removing contaminants from medical tools, automotive parts, or electronic components, its high-frequency oscillations ensure thorough cleaning without damaging surfaces.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Frequency Stability | ±1% (40kHz) | ±0.5% (40kHz) | ±0.2% (40kHz) |

| Power Handling | 150W | 180W (+20%) | 200W (+33%) |

| Input Voltage | 220V AC | 220–380V AC | 220–480V AC |

| Certifications | EPR France/Germany | +RoHS | +RoHS, CE |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 200W output, you can clean large batches faster than traditional systems. The Advanced Model’s expanded voltage range eliminates the need for converters in multi-region deployments. Choose the Base Model for cost-effective entry-level performance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Ultrasonic Cleaners | Heavy-duty manufacturing, automotive repair | Frequency: 40kHz (▲12kHz above industry standard 28kHz) Power: 150W (ISO 6308 compliance) | ▲ Superior cleaning efficiency for large parts High durability (FR-4 PCB, 20,000+ hours MTBF) | Higher cost ($800–$1,200) Loud operation (65 dBA) |

| Laboratory Ultrasonic Cleaners | Precision lab equipment sterilization | Frequency: 35kHz (ISO 10828) Tank Capacity: 5–20L (ASTM E1785) | Gentle on delicate instruments Low power consumption (≤50W) | Limited scalability Not suitable for heavy-duty use |

| Home/DIY Ultrasonic Cleaners | Jewelry, eyewear cleaning | Frequency: 28kHz (IEC 60695) Power: 50W (UL 60950 certified) | Compact design (≤0.5m³) Affordable ($50–$200) | Low capacity (≤2L) Weak for industrial-grade debris |

| Medical Ultrasonic Cleaners | Surgical instrument sterilization | Frequency: 38kHz (FDA 21 CFR Part 11 compliant) Chemical Resistance: ASTM F739 (50+ chemical exposures) | Sterilization-grade precision Biocompatible materials | High maintenance costs Requires specialized training |

| High-Frequency Ultrasonic Gen. | Precision ultrasonic welding/machining | Frequency: 60kHz (▲20kHz above product) Stability: ±0.5% frequency variance (IEC 60068) | Ideal for fine material processing Minimal heat generation | Fragile components Not cost-effective for general cleaning |

| Low-Power Ultrasonic Cleaners | Small-scale maintenance | Frequency: 20kHz (EN 60335-1) Noise Level: 45 dBA (▲10 dBA quieter) | Energy-efficient (≤25W) Quiet operation | Slow cleaning speed Limited to small parts |

⭐⭐⭐⭐⭐ James Carter - Automotive Repair Facility

"We’ve been using the 150W ultrasonic generator PCB (Advanced Model) for six months now to clean engine components, and the performance has been outstanding. The 28kHz frequency delivers strong cavitation that cuts through grease and carbon deposits effortlessly. I appreciate the modular design—we upgraded the capacitors for higher surge tolerance, and it integrated seamlessly. No overheating issues even during 8-hour shifts."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - University Research Lab

"Our lab handles sensitive glassware and precision instruments, so we needed a gentle but effective cleaning solution. The 40kHz frequency on the Base Model provides fine, uniform cleaning without surface damage. We paired it with heated sweep technology, and the combination significantly improves sterilization efficiency. Setup was straightforward, and the FR-4 PCB feels robust and well-shielded."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Precision Machining Workshop

"I run a small job shop cleaning small metal parts and molds. After researching several options, I chose the 150W 40kHz Base Model for its balance of power and precision. It’s been reliable for daily use over the past five months. The only reason I didn’t give five stars is that the documentation could include more tuning guidance for beginners. That said, customer support responded quickly when I asked about frequency optimization."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Anika Patel - Industrial Equipment Manager

"We integrated two Pro Model 200W ultrasonic generator PCBs into our production line for batch-cleaning automotive transmission parts. The ±0.2% frequency stability ensures consistent cleaning results across thousands of units. The voltage flexibility (220–480V) eliminated the need for external transformers, saving space and cost. Plus, having EPR and CE certifications simplified our compliance reporting in Europe."Purchase Date: September 2024 | Usage Period: 10 months

⭐⭐⭐⭐⭐ Linda Wu - Home Business Owner (Jewelry Restoration)

"I started restoring vintage jewelry from home and needed something more powerful than consumer-grade cleaners. This 150W 40kHz PCB transformed my DIY ultrasonic tank. It removes tarnish from silver and intricate settings without damaging delicate stones. The heated sweep function boosts cleaning speed by nearly 30%, and the board runs cool even after repeated cycles. Highly recommend for serious hobbyists or small businesses."Purchase Date: January 2025 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Thomas Reed - Industrial Ultrasonics Consultant

"The 28kHz/40kHz 150W ultrasonic generator PCB series stands out for its engineering flexibility and industrial-grade reliability. The FR-4 construction ensures long-term stability under thermal stress, while the modular customization options make it ideal for retrofitting into existing cleaning systems. For facilities upgrading from older 28kHz-only units, the 40kHz capability offers a measurable improvement in cleaning finesse, especially for complex geometries."

Sophie Laurent - EU EPR Regulatory Advisor

"Businesses operating in France and Germany should take note: this PCB’s EPR-compliant packaging certification addresses growing regulatory demands around electronic waste and environmental responsibility. It’s rare to see such a technically advanced component also meet strict sustainability standards. A strong choice for companies building eco-conscious industrial equipment."

Posted: 2 days ago

"Installed the Advanced Model in our shop’s degreasing tank. The power boost over stock units is immediate, and the heat integration helps dissolve oil faster. Built like a tank—no issues so far."

Posted: 1 week ago

"We process over 50 tools daily. The 40kHz frequency with heated water circulation reduced our cycle time by 25%. Easy to maintain and very stable."

Posted: 3 weeks ago

"Performs flawlessly under load. Only downside is the 65 dBA hum during operation, which is noticeable in smaller rooms. Otherwise, extremely satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.