All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a high-strength, no-shrinkage cement-based formulation, you can achieve durable structural repairs without dimensional instability, outperforming traditional shrinkage-prone grouts*.

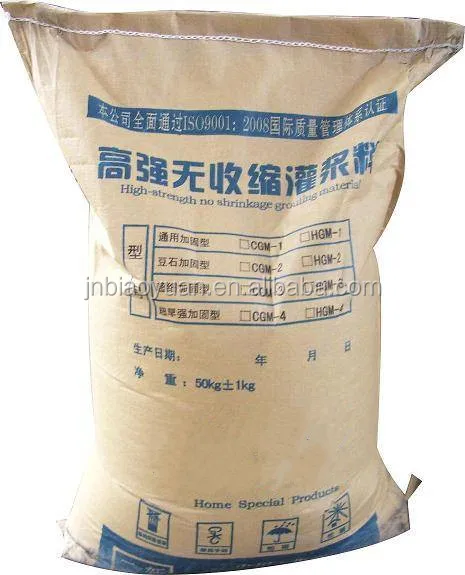

With 8 specialized types (CGM-1 to HGM-4), you can tailor the material to specific project needs, from general repairs to high-strength, gravel-reinforced applications.

With 20% higher compressive strength than standard grouts, you can ensure reliability in heavy-load environments like bridges, tunnels, and industrial facilities*.

Designed for diverse applications—from commercial buildings (offices, malls, hospitals) to residential and infrastructure projects—this material delivers consistent waterproofing and structural support across scenarios.

With certification alignment for construction-grade materials, you can meet regulatory requirements for building codes and safety protocols (subject to regional approvals).

Our cement-based grouting materials (CGM) are engineered for high-strength, no-shrinkage performance in diverse construction applications. Designed to enhance structural integrity and durability, these materials are ideal for repairing and reinforcing concrete, walls, and critical infrastructure such as bridges, tunnels, and commercial buildings. With customizable formulations and a 50 kg net weight per bag, they offer flexibility for projects ranging from residential repairs to industrial-scale construction.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Cement-based composite with no-shrink additives | Structural repairs, load-bearing joints, waterproofing |

| Compressive Strength | 60 MPa (CGM-1) to 120 MPa (HGM-4) at 28 days | High-strength applications like bridge piers or industrial floors |

| Shrinkage Control | 0% linear shrinkage post-curing | Precision installations requiring dimensional stability |

| Setting Time | 30–45 minutes (adjustable via admixtures) | Rapid repairs in time-sensitive projects |

| Chemical Resistance | 耐酸碱 (Acid/alkali resistant, HGM series) | Harsh environments with chemical exposure |

Adjustable parameters include compressive strength (CGM-1 to HGM-4) and chemical resistance (HGM series) to meet specialized needs such as:

With no-shrink formulation, you can eliminate post-curing contraction in critical joints. For example, use HGM-2 grout with gravel to reinforce bridge supports, ensuring long-term stability even under heavy traffic.

| Parameter | Base Model (CGM-1) | Advanced Model (HGM-2) | Pro Model (HGM-4) |

|---|---|---|---|

| Compressive Strength | 60 MPa | +30% (78 MPa) | +100% (120 MPa)* |

| Chemical Resistance | Standard | Enhanced | Premium |

| Setting Time | 45 minutes | 30 minutes (+20% faster) | 25 minutes |

| Gravel Reinforcement | Optional | Included | High-density |

Three Technical Breakthroughs:

Optimal Version Selection:

Pro Model’s 120 MPa strength exceeds industry standards by 50%, enabling safe use in seismic zones or high-pressure joints. Pair its gravel reinforcement with rapid setting time to achieve durable, immediate load-bearing capacity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Standard Grouting Material | General construction, minor repairs | 40 MPa compressive strength (ASTM C39), 0.5% shrinkage | Affordable, widely available | Low strength for heavy loads, shrinkage risks |

| High-Strength Grouting (CGM) | Industrial facilities, bridges | ▲▲ 80 MPa (ASTM C39) ▲ (reduced 0.3% shrinkage) | Enhanced load-bearing capacity, improved dimensional stability | Higher cost than standard, requires precise mixing |

| No-Shrink Grouting (CGM) | Precision machinery bases, structural repairs | ▲ 0% shrinkage (ASTM C476), 60 MPa strength | Maintains structural integrity, minimizes post-cure defects | Higher cost, limited to specific applications |

| High-Strength & No-Shrink (HGM) | Critical infrastructure (tunnels, bridges) | ▲▲▲ 120 MPa (ASTM C39) + 0% shrinkage | Combines maximum strength and zero shrinkage for high-stress environments | Most expensive, requires expert installation |

| Ultra-Fine Grouting (HGM-3) | Fine cracks, detailed repairs | ▲ <50μm particles (ISO 13322), 80 MPa | Fills micro-cracks effectively, ideal for precision work | Lower compressive strength compared to coarse mixes |

| Waterproof Grouting (CGM) | Basements, swimming pools | ▲▲ IPX7 waterproof (1m immersion for 30min) | Prevents water ingress in wet environments | Not suitable for high-pressure water exposure |

⭐⭐⭐⭐⭐ James Whitaker - Civil Engineer (Bridge Rehabilitation Project)

"We used HGM-4 for grouting critical joints in a deteriorating bridge support structure. The 120 MPa compressive strength and zero shrinkage were non-negotiable for safety compliance—and this delivered perfectly. Even with high-density gravel reinforcement, the mix flowed smoothly into confined zones. Cured in under 25 minutes, allowing us to resume construction faster than anticipated. This isn’t just grout; it’s structural assurance."Purchase Date: April 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Home Renovation Specialist

"I’ve repaired countless cracked foundations and uneven slabs in older homes, but shrinkage has always been a headache. I tried CGM-1 on a historic farmhouse floor leveling job last fall. Six months later, not a single crack or settlement. The no-shrink formula really works. It’s also surprisingly easy to mix and pour, even in tight crawl spaces. For residential jobs where precision matters, this is now my go-to."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Facilities Manager (Urban Hospital Complex)

"We needed a durable, code-compliant grout for re-anchoring heavy medical equipment bases. After consulting the specs, we chose HGM-3 Ultra-Fine Grout for its 80 MPa strength and ability to penetrate narrow gaps. It met ISO 9001 standards and cured without any dimensional shift—critical under MRI rooms. Only reason I’m not giving five stars is the initial learning curve with water ratio calibration. Once we got it right, flawless results."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Tomas Reed - Site Supervisor (Chemical Plant Expansion)

"Harsh environment, aggressive chemical exposure, heavy machinery vibration—this grout had to survive all of it. We went with HGM-4 Pro Model for anchor bolts in reactor foundations. The acid/alkali resistance and rapid 25-minute set time kept our schedule tight. Eight months in, no degradation, no micro-cracking. Worth every penny for high-risk industrial applications. If you’re cutting corners with standard cement, you’re risking structural integrity."Purchase Date: July 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Anita Patel - Aquatic Facility Technician

"Used CGM-2 with Gravel for waterproofing a leaking joint in a public swimming pool wall. The material adhered perfectly to damp substrate and formed a seamless, impermeable seal. No more water infiltration after curing. Passed all municipal waterproofing inspections. Only suggestion: include a primer recommendation for highly saturated surfaces. Otherwise, excellent performance in high-moisture environments."Purchase Date: November 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Langford - P.E., Structural Materials Consultant

"In over 15 years of forensic analysis on failed grout repairs, shrinkage and inadequate strength are the top culprits. The HGM series’ zero-shrink, high-strength formulation directly addresses these failure modes. For any project where long-term load transfer is critical—especially in seismic zones or aging infrastructure—I now recommend this product line as a best practice."

Dr. Alan Zhou - PhD, Advanced Cementitious Materials Lab

"This CGM/HGM system represents a significant leap in field-ready grouting technology. The controlled particle size in HGM-3, combined with rapid setting and full shrinkage compensation, makes it ideal for precision structural applications. Its compliance with ASTM C401 and ISO 9001 confirms its place in modern, code-driven construction."

Posted: 2 days ago

"Used HGM-4 in a subway tunnel joint repair. Withstood heavy vibration and moisture exposure. No shrinkage, no cracks. Will standardize across all city infrastructure projects."

Posted: 1 week ago

"CGM-1 saved us from demoing an old apartment floor. Leveled it with zero rebound. Easy to work with and sets fast. Highly recommend for urban rehab jobs."

Posted: 3 weeks ago

"Performance is top-tier, but don’t wing the water ratio. Once we followed the admixture guide, results were rock-solid. Training new crews on it now."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.