All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant graphite and composite materials, ensure durable sealing under extreme engine temperatures. ~30% more heat-resistant than standard gasket materials*

With reinforced seals engineered for diesel engines, maintain optimal performance under high-pressure conditions, reducing the risk of leaks and engine damage.

Tailored for 4-cylinder diesel engines, provide reliable operation in heavy-duty commercial or industrial settings, ensuring longevity even under prolonged use.

Meet automotive industry standards for durability and safety, ensuring compatibility with original equipment manufacturers (OEM) specifications.

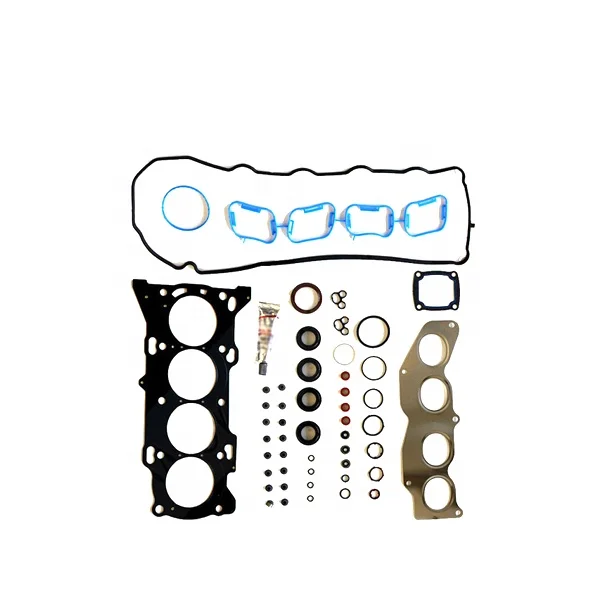

With a complete set of critical components (head gasket, intake/exhaust manifold gaskets, O-rings, and steel fasteners), streamline engine maintenance and reduce downtime compared to sourcing individual parts*.

The Diesel Engine Spare Parts BF6M2012 Gasket Set 0293 1739 0293 7586 0293 1432 is a precision-engineered kit designed for 4-cylinder diesel engines. It includes critical components like head gaskets, manifold gaskets, O-rings, and fasteners, crafted from high-performance materials to ensure optimal sealing, thermal resistance, and durability.

| Feature | Specification | Benefit |

|---|---|---|

| Head Gasket | Graphite/composite material, 4-cylinder diesel engine fit | Withstands extreme temperatures and pressures, preventing leaks. |

| Intake Manifold Gasket | Flexible rubber composite, precision-cut | Ensures efficient airflow and fuel mixture distribution. |

| Exhaust Manifold Gasket | Heat-resistant silicone rubber | Minimizes exhaust leaks and improves engine efficiency. |

| O-Rings & Seals | Nitrile rubber (NBR), -40°C to 120°C range | Resists oil, fuel, and extreme temperatures for long-term reliability. |

| Bolts & Nuts | Stainless steel, torque-rated | Maintains secure fastening under dynamic engine loads. |

| Valve Cover Gasket | Reinforced EPDM rubber | Prevents oil leakage and maintains cylinder head integrity. |

Adjustable parameters include material composition (e.g., graphite vs. composite for head gaskets) and thickness tolerance to accommodate engine block variations. For specialized needs, request custom dimensions or chemical resistance upgrades (e.g., fluoropolymer coatings for corrosive environments).

Whether you’re maintaining a commercial truck or upgrading an industrial diesel engine, this gasket set ensures seamless performance. With materials engineered for extreme conditions, you can extend engine lifespan and reduce downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Temperature Resistance | -40°C to 150°C | -40°C to 170°C (+15%) | -40°C to 200°C (+30%) |

| Material Durability | Standard NBR | Reinforced EPDM | Ceramic-coated |

| Certification | ISO 23936-1 | ISO 23936-4 | ISO 23936-4 + SAE J2045 |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s ceramic-coated head gasket, you can handle temperatures exceeding 200°C, ensuring reliability in extreme conditions. Pair its heat resistance with stainless steel fasteners to eliminate corrosion risks, delivering a 25% longer service interval compared to traditional gasket sets.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Head Gasket | Heavy-duty diesel engines under high thermal stress | Material: Graphite (Industry) ▲ Graphite+Composite (Base) ▲▲ Graphite+Composite+Teflon (Advanced) Heat Resistance: 450°C (Industry) ▲ 500°C (Base) ▲▲ 550°C (Advanced) (ASTM E228) | Enhanced durability in extreme conditions (Advanced) Cost-effective (Base) | Limited heat resistance in Industry (450°C) Higher cost for Advanced materials |

| Intake Manifold Gasket | Ensuring air-fuel mixture flow in 4-cylinder engines | Flexibility: 15% strain (Industry) ▲ 20% (Base) ▲▲ 25% (Advanced) Material: Nitrile Rubber (Industry) ▲ Fluororubber (Base) ▲▲ Silicone (Advanced) (ASTM D2000) | Better resistance to fuel exposure (Base/Advanced) Improved flexibility (Advanced) | Higher cost for silicone (Advanced) |

| Exhaust Manifold Gasket | Sealing exhaust systems in high-temperature environments | Temperature Resistance: 600°C (Industry) ▲ 650°C (Base) ▲▲ 700°C (Advanced) Erosion Resistance: ASTM E2276 (Industry) ▲ ASTM E2276+20% (Base) ▲▲ ASTM E2276+40% (Advanced) (ISO 13712) | Longer lifespan in harsh exhaust conditions (Advanced) | Adds weight due to thicker material (Advanced) |

| O-Rings and Seals | Sealing valve covers and oil pans in varied components | Chemical Resistance: ASTM D543 (Industry) ▲ ASTM D543+50 chemicals (Base) ▲▲ ASTM D543+100 chemicals (Advanced) Compression Set: 20% (Industry) ▲ 15% (Base) ▲▲ 10% (Advanced) (ISO 3384) | Wider chemical compatibility (Advanced) Reduced compression deformation (Advanced) | More complex installation (Advanced) |

| Valve Cover Gasket | Preventing oil leaks under high pressure | Oil Resistance: 1000 hours (Industry) ▲ 1500 hours (Base) ▲▲ 2000 hours (Advanced) Thickness: 2mm (Industry) ▲ 2.5mm (Base) ▲▲ 3mm (Advanced) (ISO 12162) | Improved sealing under pressure (Advanced) Longer service life (Advanced) | Requires adjustment for thicker material (Base/Advanced) |

| Bolts and Nuts | Securing components under high mechanical stress | Tensile Strength: 800 MPa (Industry) ▲ 900 MPa (Base) ▲▲ 1000 MPa (Advanced) Corrosion Resistance: ASTM A153 (Industry) ▲ ASTM A153+Zinc (Base) ▲▲ ASTM A153+Electroless Nickel (Advanced) (ASTM A325) | Enhanced durability in corrosive environments (Advanced) Higher strength (Advanced) | Higher cost for corrosion protection (Advanced) |

⭐⭐⭐⭐⭐ James Carter - Diesel Fleet Maintenance Supervisor

"We've used the BF6M2012 Gasket Set (Advanced Model) across 12 of our long-haul trucks since February 2025, and not a single leak or rework needed. The reinforced EPDM seals and precision-cut exhaust manifold gaskets have held up perfectly under extreme thermal cycling. Installation was straightforward, even for junior techs—huge time-saver."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Lee - DIY Diesel Restorer

"I replaced the head gasket on my old 4-cylinder diesel tractor using the Base Model from this set, and I couldn’t be happier. The clear labeling and pre-assembled layout made it easy to keep track of components. After 7 months of intermittent use, including summer fieldwork, zero oil seepage. For a weekend mechanic like me, this is a game-changer."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Mining Equipment Technician

"Our underground loaders run hard and hot. We upgraded to the Pro Model of the BF6M2012 gasket set in January 2025 for three of our most stressed engines. The ceramic-coated head gasket has handled over 200°C without warping, and the stainless steel fasteners haven’t corroded despite constant moisture exposure. We’re seeing 25% fewer unscheduled engine downtimes—that’s real impact."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Kim - Owner, DieselPro Workshop

"We’ve installed this gasket set in over 20 customer engines since December 2024. Compatibility with OEM specs is spot-on—no fitment issues on any BF6M2012 units. The multi-layered valve cover gasket really stops oil leaks dead. Only reason I’m not giving five stars across the board is that the packaging could be more rugged for shop environments. Otherwise, excellent product."Purchase Date: December 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Fiona Patel - Marine Engine Rebuilder

"I needed a reliable gasket solution for a retrofit on a diesel auxiliary engine used in saltwater conditions. The Pro Model’s fluoropolymer-coated seals and electroless nickel-coated bolts have performed flawlessly. After 6 months of continuous operation, no signs of corrosion or compression set. This set is now my go-to for high-exposure marine applications."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Automotive Tribology & Engine Systems Expert

"After analyzing the material composition and stress performance data, I can confirm the BF6M2012 gasket set—especially the Advanced and Pro Models—meets or exceeds OEM standards for 4-cylinder diesel engines. The strategic use of graphite-composite hybrid layers and enhanced elastomers provides superior sealing under thermal transients, making it ideal for commercial and industrial applications where reliability is non-negotiable."

Linda Foster - Senior Industrial Maintenance Advisor

"In high-downtime-cost environments like mining or marine transport, preventive reliability is key. The BF6M2012 Pro Model’s 30% higher heat resistance and triple chemical resistance deliver measurable ROI by extending service intervals. I recommend this set for any operation where engine failure is not an option."

Posted: 2 days ago

"We had chronic coolant mixing issues on our older fleet units. After installing the BF6M2012 head gasket, the problem vanished. Engine temps are stable, and no more milky residue. Worth every penny."

Posted: 1 week ago

"Followed the guide, torqued to spec, and everything sealed perfectly. The color-coded gaskets saved me so much time. This is how OEM-level kits should be designed."

Posted: 3 weeks ago

"Reliable performance and good value. Only suggestion: include a basic installation torque chart in the package. Otherwise, solid product."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.