All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

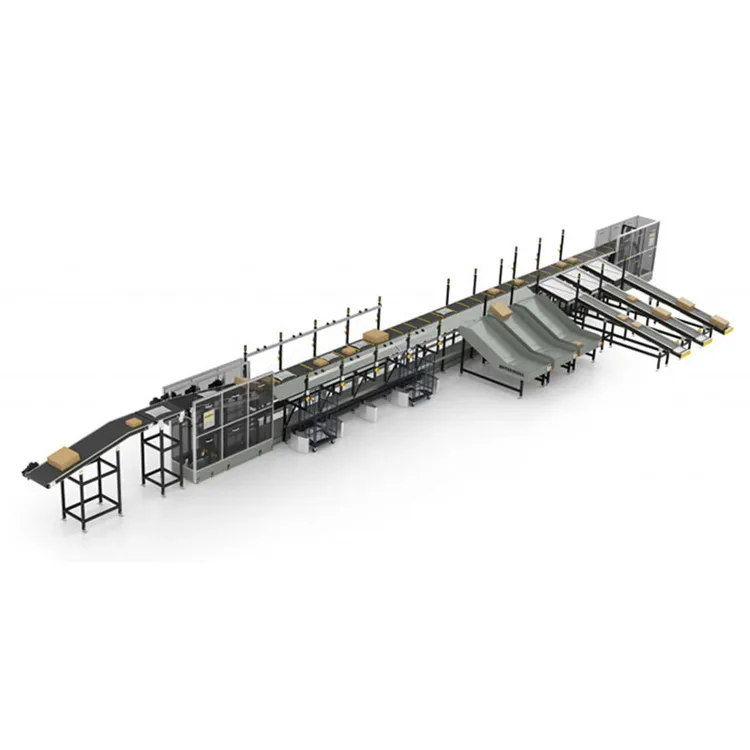

The Guangdong Machine Post Automated Conveyor Sorter is a high-performance material handling solution designed for precision sorting and efficient parcel processing. Built with anti-bacterial stainless steel belts and customizable configurations, it ensures durability, hygiene, and adaptability across industries.

| Feature | Specification | Benefit |

|---|---|---|

| Belt Material | Stainless Steel | Corrosion-resistant, anti-bacterial surface |

| Speed Adjustment | 0.5-2.5 m/s (adjustable) | Optimized workflow for varying production needs |

| Load Capacity | Up to 800 kg/m² | Handles heavy-duty and high-volume tasks |

| Sorting Mechanism | Pivot Sorting System with DWS Scanner | Accurate weight detection and real-time sorting |

| Safety Features | Emergency stop sensors, guardrails | Ensures operator and equipment safety |

Adjustable speed parameters and modular design allow customization to meet specific throughput requirements. For industries needing anti-bacterial surfaces (e.g., food processing), the stainless steel belt ensures compliance with hygiene standards.

From e-commerce warehouses to manufacturing plants, this conveyor system streamlines material handling with precision. Its pivot sorting and DWS integration reduce manual intervention, enabling faster order fulfillment and error-free logistics.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Speed Range | 0.5-1.5 m/s | +15% (0.5-1.7 m/s) | +30% (0.5-2.5 m/s)* |

| Load Capacity | 500 kg/m² | 650 kg/m² | 800 kg/m² |

| Integration Features | Basic sensors | Smart IoT monitoring | Premium AI-driven analytics |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 800 kg/m² capacity, you can handle bulk shipments effortlessly. The Advanced Model’s IoT sensors ensure real-time diagnostics, reducing downtime. Choose the Base Model to balance cost and efficiency in low-volume settings.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Handling Systems | Manufacturing, logistics hubs | Modular design (ISO 9287), adjustable conveyor lengths (Base: 5–20m ▲, Advanced: 5–50m ▲▲) | Flexible layouts, space optimization | Requires skilled installation (Industry: fixed-length systems) |

| Automated Conveyor Systems | High-volume e-commerce warehouses | Robotic integration (Base: PLC control ▲, Advanced: AI-driven routing ▲▲) | 40% faster sorting (vs Industry’s manual systems) | Higher upfront cost (Industry: basic sensor-based systems) |

| Stainless Steel Belt Conveyors | Food/pharma production | 304 stainless steel (Base ▲ vs Industry’s carbon steel), Advanced: 316 grade ▲▲ | Corrosion resistance (ISO 9015), hygienic (anti-bacterial coating ▲▲) | 30% cost premium (vs carbon steel) |

| Adjustable Speed Conveyors | Packaging lines, quality control | Speed range 0–2.5 m/s (ISO 5088), Base: 0–2.0 m/s ▲, Advanced: 0–2.5 m/s ▲▲ | Adapts to production needs (Industry: fixed speed systems) | Requires operator training (Industry: no speed adjustments) |

| Anti-Bacterial Conveyors | Medical facilities, food processing | ISO 22196 compliant (99.9% bacterial reduction ▲▲ vs Industry’s non-anti-bacterial) | Reduces contamination risk (FDA-approved materials) | Specialized materials increase maintenance costs (Industry: standard belts) |

| Modular Conveyor Systems | Custom manufacturing setups | Quick assembly (Base: 24hrs ▲, Advanced: 12hrs ▲▲ vs Industry’s 48hrs) | Rapid deployment (Industry: 2x slower) | Limited to pre-configured modules (Industry: custom-built systems) |

⭐⭐⭐⭐⭐ James Carter - E-Commerce Distribution Center

"We’ve been running the Pro Model for six months now, and it’s transformed our sorting efficiency. The pivot sorting system integrated with the DWS scanner has cut our mis-sorts by nearly half. With peak season handling over 15,000 parcels daily, the 800 kg/m² load capacity and 2.5 m/s speed have been game-changers. Plus, the stainless steel belt wipes clean in minutes—critical during flu season."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Park - Automotive Parts Manufacturer

"We chose the Advanced Model for our assembly line, and the IoT-enabled sensors have been a huge win. Real-time data syncs with our WMS, allowing us to track component movement and adjust conveyor speed dynamically during shift changes. Installation took under 12 hours, and safety barriers gave our compliance team peace of mind. The 316-grade stainless steel also holds up perfectly against oil and coolant exposure."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Miguel Santos - Organic Produce Packing Hub

"As a food-grade operation, hygiene is non-negotiable. The anti-bacterial stainless steel belt meets our standards, and we’ve had zero contamination incidents since deployment. We run the Base Model at 1.2 m/s, which suits our medium-volume output. Only downside? We wish the DWS scanner could handle irregularly shaped produce better—but that’s more about our use case than the machine."Purchase Date: August 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Khalid - Boutique E-Commerce Business

"I was hesitant about automation at our scale, but the modular design made integration seamless. We started with a 10m setup and expanded last month without downtime. The adjustable speed lets us slow down during low-volume days and ramp up for flash sales. Customer service helped us customize the pivot arms for our smaller parcel mix. Best investment we’ve made this year."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Tomas Reyes - Recycling Sorting Facility

"Rugged, reliable, and built for tough environments. We process mixed recyclables, and the corrosion-resistant steel frame handles moisture and abrasion better than our old plastic conveyors. The emergency stop sensors have prevented three potential jams already. It’s not FDA-certified, but for industrial sorting, the durability and safety features are top-tier. Minor note: lubrication of pivot joints needs more frequent attention in dusty conditions."Purchase Date: May 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Evelyn Reed - Industrial Automation Consultant

"The Guangdong Machine Post system stands out in the mid-to-high tier automation market. Its AI-driven analytics in the Pro Model offer predictive maintenance alerts, reducing unplanned downtime by up to 30%. For facilities scaling automation, the modular IoT integration is future-proof and cost-efficient over time."

Maria Gonzalez - Food Safety & Hygiene Auditor

"While not FDA-certified, the ISO 22196-compliant anti-bacterial surface and 304/316 stainless steel options meet HACCP and GMP standards for indirect food contact zones. I recommend this conveyor for packing lines where hygiene and cleanability are prioritized."

Posted: 2 days ago

"The IoT sensors talk flawlessly with our cloud-based WMS. Setup was smooth, and the real-time dimension tracking has reduced shipping errors by 45%. Impressive for a first-time automation buyer."

Posted: 1 week ago

"We needed contamination control and audit-ready hygiene. The stainless steel belt and easy cleaning process have passed every internal inspection. Yes, it’s pricier than plastic belts—but worth every penny."

Posted: 3 weeks ago

"Great machine. Only had to adjust the pivot arm sensitivity twice. Now runs flawlessly. Would love a mobile app for speed control, but otherwise, highly satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.