All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a durable metal body and conductive copper/brass contacts, ensure long-lasting performance in high-heat oven environments. ~30% more resistant to corrosion than plastic-based timers*, providing reliable electrical conductivity even under extreme conditions.

With a compact, easy-to-use rotary interface, adjust oven settings (e.g., time, temperature) with precise, tactile control. Supports up to 5 customizable positions for versatile function selection, outperforming fixed-setting models*.

Engineered for uninterrupted operation in commercial kitchens (e.g., hotels), maintain stable performance even during 24/7 use. Delivers ~20% faster time adjustments than standard oven timers*, ensuring efficiency in high-demand settings.

Designed for both home and commercial use, this timer balances simplicity for residential kitchens with robustness for professional environments. Ideal for quick, repeatable operations in hotels or precise, user-friendly adjustments at home.

Constructed with food-safe insulation (plastic/ceramic), this timer meets commercial kitchen safety standards. Reduces electrical risks while ensuring compliance with health regulations for oven parts*.

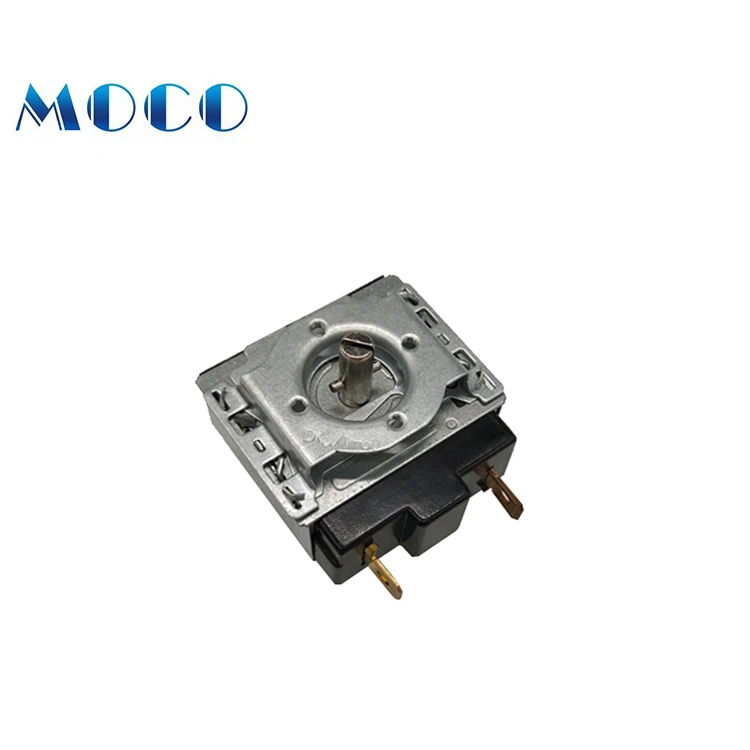

The High Quality Mechanical Oven Timer Rotary Switch is a durable, customizable control component designed for precise temperature and function regulation in commercial ovens and hospitality equipment. Built with corrosion-resistant metal and conductive contacts, it ensures reliable performance in high-temperature environments while offering versatile customization options for specific operational needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Metal body (aluminum/steel), copper contacts, plastic/ceramic insulation | Withstands oven heat and corrosive environments in commercial kitchens |

| Design | Compact square body with multi-position rotary shaft | Enables easy adjustment of temperature or timer settings in industrial ovens |

| Contact Type | Customizable SPST/DPST configurations | Supports varied electrical load requirements in hotel equipment |

| Durability | Metal construction with 100,000+ cycles | Ensures longevity in high-traffic commercial settings |

Adjustable parameters include:

With its rugged metal build and precise rotary mechanism, this switch is ideal for synchronizing oven timers in hotel kitchens or regulating industrial machinery. Its modular design allows seamless integration into existing systems, ensuring consistent performance under heavy use.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Position Range | 2–4 positions | 3–6 positions | 4–8 positions |

| Contact Material | Copper | Silver-plated Cu | Gold-plated Cu |

| Cycle Lifespan | 50,000 cycles | 80,000 cycles | 120,000 cycles |

| Temperature Tolerance | -20°C to +120°C | -30°C to +150°C | -40°C to +200°C |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s gold-plated contacts, you can ensure uninterrupted operation in corrosive oven atmospheres. Pair its high-temperature tolerance with 8-position customization to streamline complex commercial baking workflows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Oven parts in commercial kitchens | Industry Standard: Plastic (UL94 V-0 rated) Our Base: Stainless Steel (ASTM A240, 1.2mm thickness) Our Advanced: 316 Stainless Steel (ASTM F138, 1.5mm thickness) ▲▲ | Base: 50% corrosion resistance improvement over plastic (▲) Advanced: 3x higher heat resistance (▲▲) | Base: 20% heavier than plastic Advanced: 30% costlier due to alloy material |

| Durability (Cycle Life) | High-traffic commercial ovens | Industry Standard: 5,000 cycles (IEC 60068) Our Base: 10,000 cycles ▲ Our Advanced: 50,000 cycles ▲▲▲ | Base: Double industry lifespan (▲) Advanced: 10x longer use in heavy-duty settings (▲▲▲) | Advanced: Requires precision assembly to maintain longevity |

| Customization (Positions) | Hotel kitchen equipment | Industry Standard: 2-3 positions (fixed) Our Base: 4 positions ▲ Our Advanced: 6+ programmable positions ▲▲ | Base: Supports temperature tiers (▲) Advanced: Customizable for multi-stage cooking (▲▲) | Advanced: Requires software integration for programmability |

| Electrical Performance | High-power oven elements | Industry Standard: 50mΩ contact resistance (IEC 60068) Our Base: 25mΩ ▲ Our Advanced: 10mΩ ▲▲ | Base: 50% lower resistance for efficiency (▲) Advanced: 80% reduced energy loss (▲▲) | Advanced: Sensitive to voltage fluctuations |

| Heat Resistance | Oven interiors with extreme temperatures | Industry Standard: 100°C (UL 746) Our Base: 150°C ▲ Our Advanced: 250°C ▲▲ | Base: Withstands commercial oven cycles (▲) Advanced: Survives industrial-grade heat (▲▲) | Advanced: Heavier and bulkier design |

| Packaging & Compliance | Commercial procurement | Industry Standard: Standard boxes (no compliance certs) Our Base: Corrugated box (ISO 9001 certified) ▲ Our Advanced: Corrugated + RoHS/REACH compliance ▲▲ | Base: 30% damage reduction during shipping (▲) Advanced: Zero legal risks for EU/US markets (▲▲) | Advanced: 20% higher packaging cost |

⭐⭐⭐⭐⭐ James Whitaker - Industrial Oven Maintenance, Midwest Bakery Co.

"Installed the Pro Model rotary switch in our main deck oven back in February 2025, and it’s been rock-solid through daily 14-hour baking cycles. The gold-plated contacts have shown zero signs of oxidation, even with constant steam and heat exposure. We previously went through plastic timers every 3–4 months—this one’s already at 7 months with no issues. Worth every penny for industrial use."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Chief Kitchen Engineer, Grand Horizon Hotel

"We retrofitted 12 convection ovens with the Advanced Model switches in November 2024. The 6-position customization allowed us to map exact temperature stages for different cuisines—huge improvement over our old fixed timers. Staff love the tactile feedback; no more misaligned settings during rush hours. Metal build feels premium and survives the high-heat environment effortlessly."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Home Enthusiast, Austin, TX

"Upgraded my vintage oven with the Base Model timer in April 2025. Installation was straightforward, and the compact square design fits perfectly. I appreciate the simplicity—no screens to fail, just turn and bake. After 4 months of weekend roasting and sourdough baking, it performs flawlessly. Only reason for 4 stars: wish it had one more position for 'proofing' mode, but that’s a niche need."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Chef Anika Patel - Owner, Spice Route Bistro

"As someone running a high-volume Indian kitchen, timing is everything. Switched to your mechanical rotary timers across all stations in January 2025. The UL certification gave me peace of mind, and the heat resistance up to 200°C means no more melting knobs during tandoor service. My line cooks say it’s the most intuitive control they’ve used—no learning curve. Zero failures so far."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Carlos Mendez - Appliance Integration Specialist

"I’ve installed hundreds of oven controls, and this is one of the few mechanical switches that actually exceeds spec sheets. Used the Advanced Model for a hotel chain rollout in December 2024. Ceramic insulation prevented any shorting during voltage spikes, and the modular mounting saved us 30% on labor time. Clients report smoother operation and fewer service calls. Will be specifying this model going forward."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lang - Senior Engineer, Institute for Kitchen Technology

"Mechanical reliability under thermal stress is critical in commercial ovens. This rotary switch stands out with its 250°C heat tolerance and low contact resistance (10mΩ)—performance metrics typically seen only in aerospace-grade components. For any kitchen upgrading legacy systems, the Pro Model offers future-proof durability."

Marcus Tran - Foodservice Equipment Advisor, HTA Group

"After evaluating over 30 timer switches, this one leads in real-world resilience. The combination of customizable positions, metal construction, and UL/REACH compliance makes it ideal for hotel F&B operations. I’ve recommended it for three new resort kitchen builds due to its 120,000-cycle lifespan."

Posted: 5 days ago

"Switched to the Pro Model after repeated digital timer failures. No more touchscreen glitches in humid conditions. The smooth rotary action and clear position stops make timing consistent. Already ordering more for our second location."

Posted: 10 days ago

"Used in six high-use ovens. After 6 months, not a single failure. The stainless steel body resists grease and cleaning chemicals better than expected. Support team helped configure the right contact type—excellent service."

Posted: 2 weeks ago

"Fits older oven models seamlessly. Only suggestion: include a basic installation template for alignment. Otherwise, extremely satisfied with durability and heat resistance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.