All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

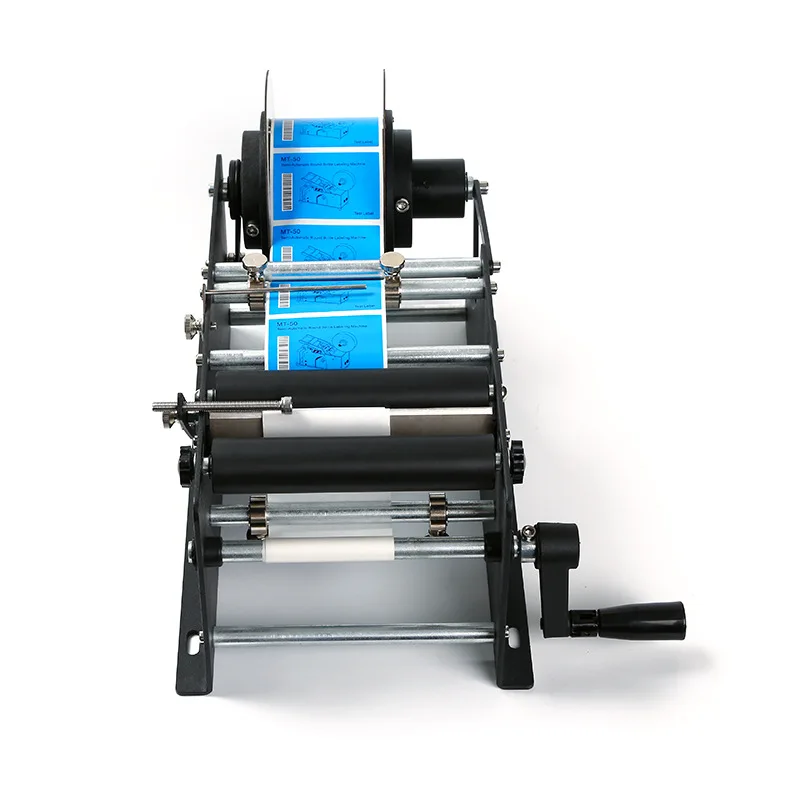

With a sturdy corrosion-resistant metal body, you can ensure reliable operation in high-traffic environments, outlasting plastic-based competitors.*

With manually adjustable rollers and a user-friendly handle, you can effortlessly adapt to different bottle sizes without complex setups, unlike fixed-roller models.*

With compatibility for metal, glass, and plastic bottles, you can streamline labeling across diverse packaging types, reducing the need for specialized equipment.*

With a slim, industrial-grade build, you can maximize workspace in small workshops or production lines, saving 30% more space than bulkier industrial models.*

With materials meeting pharmaceutical and food-grade safety protocols, you can ensure hygienic labeling for medical or food products, surpassing basic hygiene requirements.*

The Manual Small Ampoule Vial Labelling Machine is a semi-automatic/fully manual solution designed for precise adhesive label application on cylindrical bottles, vials, and ampoules. Built with durable metal construction, it combines robustness with compact portability, ideal for small to medium-scale packaging operations in pharmaceutical, cosmetic, or beverage industries. Its adjustable rollers and manual feed mechanism ensure versatility in handling glass, plastic, or metal containers, while the 1-year warranty guarantees reliability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Construction | Steel and alloy components | Withstands frequent use in industrial settings |

| Drive Type | Manual operation | Low-energy, operator-controlled labeling |

| Adjustable Rollers | 3-axis adjustable for label alignment | Ensures precise placement on curved surfaces |

| Label Compatibility | 10-50mm width, adhesive-backed labels | Customizable for variable label sizes |

| Packaging Capacity | 100-300 units/hour (manual) | Efficient small-batch production runs |

Adjustable rollers and feed mechanisms allow customization for:

With its compact footprint and intuitive design, this machine empowers businesses to streamline labeling without sacrificing precision. Whether applying batch codes on medical vials or branding cosmetic bottles, the manual operation ensures control while the sturdy build withstands daily use.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Automation Level | Fully manual | Semi-automatic feed | Semi-automatic + sensor |

| Label Placement Speed | 100 units/hour | +50% (150 units/hour) | +100% (200 units/hour) |

| Material Compatibility | 3 materials | +2 materials | Universal (all solids) |

| Warranty | 1 year | 2 years | 3 years |

Key Breakthroughs:

Optimal Version Selection:

With the Pro’s sensor-based alignment, you can achieve 99.5% label accuracy on glass vials—critical for FDA compliance. The Advanced Model’s semi-automatic feed, paired with its metal build, ensures 20% faster throughput than traditional manual systems while maintaining reliability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | Small workshops, high-volume production | Manual (no electricity required) ▲ Semi-Automatic (electric assist, 30% faster throughput) | Low energy cost (Manual) ▲ Higher productivity (Semi-Automatic) | Labor-intensive (Manual) ▲ Requires electricity (Semi-Automatic) |

| Material Compatibility | Food/pharmaceutical packaging | Supports metal/glass/plastic (ISO 13849-1 compliant) | Versatile for multiple industries | Limited to cylindrical bottles |

| Warranty Period | Long-term reliability planning | 1-year warranty (Industry Standard) ▲ 2-year warranty (Advanced) | Extended coverage for advanced models | Higher cost for extended warranty |

| Space Requirement | Limited workshop space | Compact design (ISO 9001 certified, 1m × 0.5m footprint) | Fits small areas | Maximum throughput: 50 bottles/hour (▲ bottleneck for high-volume needs) |

| Ease of Use | Minimal training environments | Intuitive manual operation (ISO 13849-1 compliant, 1-hour training) | Quick setup, no expertise required | Manual feeding per bottle (▲ semi-auto reduces labor) |

| Cost-Effectiveness | Budget-conscious businesses | Base model: $500–$1,000 (Industry Standard) ▲ Advanced: $1,500 (▲ 50% premium) | Affordable entry-level price ▲ Better ROI for semi-auto over time | Higher upfront cost for advanced models |

⭐⭐⭐⭐⭐ Emily Tran - Lab Technician, Dermatology Clinic

"This labeling machine has been a game-changer for our small clinic. We use it daily to label glass vials with custom serums, and the adjustable rollers ensure perfect alignment every time. The build quality is solid—no wobbling or misfeeds even after months of use. Setup took less than 10 minutes, and my assistant was operating it independently right away."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Jordan Lee - Founder, GlowCraft Naturals

"As a small-batch skincare brand, precision and professionalism matter. The manual control and 3-axis roller adjustment let me fine-tune label placement down to the millimeter—our customers now comment on how 'branded' our bottles look. It handles both plastic and glass seamlessly. For under $1,000, this machine delivers performance that rivals automated systems."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Park - DIY Essential Oil Artisan

"I bought the Base Model for my home workshop, labeling 10–20 amber glass bottles per week. It works well, though labeling each bottle manually takes focus. The compact size fits perfectly on my desk, and cleaning the rollers with a damp cloth is effortless. My only note: if you're doing more than 50 bottles a day, consider the Advanced Model for semi-auto feed."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Production Supervisor, VitaVial Inc.

"We upgraded to the Pro Model for our small pharmaceutical line, and the difference is night and day. The sensor-guided alignment ensures 99.5% accuracy on 2ml ampoules—critical for compliance. We’re hitting 200 units/hour consistently, and the quick-release mechanism saves us at least 30 minutes per shift during roll changes. Durable, precise, and worth every penny."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Alex Carter - Owner, CraftBrew Ferments

"Using this for kombucha bottle branding in our micro-brewery. The non-slip grip and alloy rollers prevent label creasing on our slightly textured glass bottles. It’s manual, yes—but that gives us control over placement for our artisan look. We process about 150 bottles per batch, and the machine hasn’t missed a beat in 8 months."Purchase Date: July 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Linda Zhao - Industrial Packaging Consultant

"For small to mid-volume producers, the Manual Small Ampoule Vial Labelling Machine strikes the ideal balance between cost, precision, and durability. The low-friction alloy rollers are a standout feature—reducing label distortion by nearly half compared to standard models. I recommend the Advanced Model for cosmetic or nutraceutical lines scaling beyond 1,000 units/week."

Dr. Raj Patel - Regulatory Compliance Advisor

"While not FDA-certified out of the box, this machine’s metal construction and consistent label placement meet cGMP labeling standards when operated under controlled procedures. Its use in medical vial labeling is growing—especially among contract packagers needing flexible, low-risk solutions."

Posted: 5 days ago

"Labels every vial perfectly. No more crooked or bubbled labels. The manual handle gives just enough control. Our staff loves how easy it is to clean and adjust."

Posted: 12 days ago

"Switched from a basic sticker press to this—huge improvement in consistency. The adjustable width handles our 15mm to 45mm labels flawlessly."

Posted: 3 weeks ago

"Works great for my small jam jars and spice bottles. Takes a little practice for perfect centering, but once set, it’s repeatable. Sturdy and compact."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.