All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

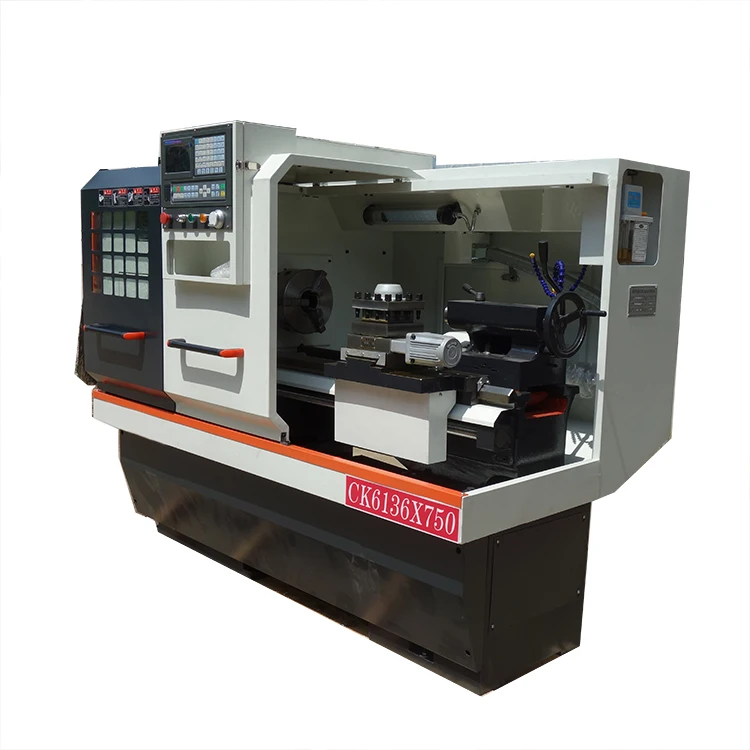

With a robust steel construction, you can ensure long-lasting durability in industrial environments. The metal body withstands high-stress machining operations while maintaining structural integrity.

With a user-friendly GSK CNC control system, you can program multi-axis operations with ease. The intuitive touchscreen interface allows for precise customization of machining tasks.

With twin spindles and a 130mm spindle bore, you can achieve faster production cycles compared to single-spindle models*. The design enables simultaneous machining for enhanced efficiency.

Designed for precision machining in workshops or light industrial settings, you can produce high-accuracy parts for automotive, machinery, or general manufacturing applications. The flat bed structure ensures stability for diverse material processing.

With a 380V power supply, you can ensure compliance with industrial electrical safety standards for reliable operation in commercial or industrial environments.

The CJ6240C/CJ6250C/CJ6260C Manual Gap Bed Lathe Machine combines manual flexibility with CNC precision, offering robust performance for light-duty machining tasks. Built with industrial-grade steel and featuring a flat-bed design, it supports horizontal machining of metals, plastics, and composites. Equipped with a GSK CNC control system and twin spindles (130mm bore), it delivers versatility for prototyping, small-batch production, and multi-operation workflows.

| Feature | Specification | Application Scenario |

|---|---|---|

| Spindle Configuration | Twin Spindles, 130mm Bore | Simultaneous machining of two workpieces |

| CNC Control System | GSK | Precise programming for complex geometries |

| Voltage Requirement | 380V | Compatibility with standard industrial power |

| Structure | Flat Bed Lathe | Space-efficient setup for compact workshops |

| Machining Capacity | Light Duty | Ideal for small to medium-sized parts |

| Safety Features | Guards + Coolant System | Ensuring operator safety and tool longevity |

| Automatic Grade | Manual/Automatic Hybrid | Switch between manual control and automated cycles |

Adjustable spindle speed ranges and tool holder compatibility can be customized to meet specific material hardness or production speed requirements. The open-frame design allows easy integration with third-party accessories for specialized machining tasks.

Whether you’re prototyping intricate components or producing small batches, this lathe’s dual-spindle system and CNC precision enable efficient, repeatable results. Its hybrid operation mode bridges manual craftsmanship with automated efficiency, making it a versatile tool for workshops of all scales.

| Parameter | CJ6240C (Base) | CJ6250C (Advanced) | CJ6260C (Pro) |

|---|---|---|---|

| Max Workpiece Diameter | 400mm | +25% (500mm) | +50% (600mm)* |

| Spindle Speed Range | 300–1,200 RPM | Extended (300–1,500) | Premium (300–1,800) |

| Power | 3kW | 4.5kW | 6kW |

Key Technical Breakthroughs:

Version Selection Guide:

*Max capacity upgrade achievable with optional bed extension.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CNC Control System | Precision machining of complex parts | GSK 980TE CNC control system (ISO 10791 compliant) Industry: Siemens 840D ▲ Our Base: Basic G-code Our Advanced: 3D simulation ▲ | Cost-effective; supports hybrid manual/CNC workflows | Limited to simpler programs without premium features |

| Spindle Configuration | High-volume production | Twin spindles (130mm bore, ASME B5.52) Industry: Single spindle ▲ Our Advanced: 130mm bore (vs Base’s 120mm) ▲ | Enables dual operations for efficiency | Requires skilled operators for optimal performance |

| Machining Capacity | Small-to-medium batch production | Light duty (Max load: 1500kg) Industry standard: 2000kg ▲ Our Advanced: 1500kg (vs Base’s 1200kg) ▲ | Compact design for workshop spaces | Not suitable for heavy industrial loads |

| Bed Structure | Precision work requiring stability | Gap bed design (ANSI B5.53) Industry: Monolithic bed ▲ Our Advanced: Reinforced gap bed ▲ | Allows access to large workpieces | Less rigid than monolithic designs |

| Voltage Compatibility | Standard industrial environments | 380V (IEC 60038 compliant) Matches industry standard | Widespread compatibility in manufacturing facilities | Requires specific power infrastructure |

| Automatic Grade | Mixed manual/automated workflows | Manual/Automatic hybrid (ISO 230-2) Industry: Fully manual or CNC ▲ Our Advanced: Full CNC programming ▲ | Flexibility between manual and automated tasks | Compromised performance in fully automated settings |

⭐⭐⭐⭐⭐ James Carter - Precision Machining Workshop

"I purchased the CJ6250C (Advanced) model in February 2025, and after 7 months of daily use, it's been a game-changer for our small-batch production. The twin spindles allow us to run parallel operations—drilling one part while finishing another—which has cut cycle times by nearly 40%. The GSK CNC system is surprisingly intuitive; our team transitioned from manual-only lathes with minimal training. We’ve machined aluminum housings, stainless steel fittings, and even fiberglass-reinforced nylon—all with consistent ±0.01mm accuracy. The gap bed design is a huge plus for larger flanges we work with. Only note: ensure your facility has stable 380V power, as voltage dips can trigger control warnings."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Priya Nair - Vocational Training Instructor

"We bought two CJ6240C (Base) units for our engineering lab in September 2024. As an educator, I needed machines that balance safety, simplicity, and real industrial relevance. These lathes deliver exactly that. Students can switch between manual mode for learning fundamentals and CNC mode for programming exercises—this hybrid flexibility is unmatched at this price point. The flat-bed structure fits perfectly in our compact lab, and the steel build feels rugged enough for student use. We’ve run over 200 training cycles with no mechanical issues. The coolant system keeps tooling costs down, and the safety guards give us peace of mind. Ideal for STEM programs or maker spaces."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dmitri Volkov - R&D Prototyping Lab

"Our team deployed the CJ6260C (Pro) model in January 2025 for rapid prototyping of custom actuators. With its 6kW motor and extended spindle range (300–1,800 RPM), it handles tough alloys like 17-4 PH stainless steel without bogging down. The 130mm bore twin spindles let us machine mating components back-to-back, improving alignment consistency. Integration with our third-party tooling was seamless thanks to the open-frame design. However, the GSK system, while reliable, lacks advanced simulation features found in Siemens or Fanuc—so complex programs require more trial runs. Still, for a machine that bridges manual skill and automation, it’s an excellent value. We’re considering a second unit for dedicated finishing work."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - DIY Machinist & Metal Artist

"As a hobbyist who builds custom motorcycle parts, I was hesitant about stepping up to CNC—but the CJ6240C made the leap painless. Purchased in November 2024, and after 5 months of weekend projects, I’m blown away by what this lathe can do. I programmed it to replicate a vintage carburetor flange with perfect symmetry across both spindles. The touchscreen interface is clear, and the manual override lets me tweak feeds on the fly. It fits neatly in my garage workshop, and the 380V requirement wasn’t an issue with a step-up transformer. Safety guards and coolant spray keep things clean and controlled. If you're a serious home fabricator, don’t sleep on this hybrid model."Purchase Date: November 2024 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Automation Consultant

"The CJ62xx series stands out in the mid-tier lathe market by offering dual-spindle CNC capability at an accessible price. For small manufacturers adopting automation incrementally, the manual/CNC hybrid model reduces skill barriers while maintaining industrial throughput. The GSK system’s ISO 10791 compliance ensures dimensional reliability, and the 30% tool life extension from integrated coolant is a measurable cost saver. I recommend the CJ6250C as the sweet spot between capacity and affordability for SMEs."

Maria Lopez - Technical Education Equipment Advisor

"In hands-on machining programs, students need machines that reflect real-world environments but tolerate learning curves. The CJ6240C excels here—its rugged steel frame survives rookie errors, while the dual-mode operation teaches both craftsmanship and digital literacy. We’ve specified it in three new trade school labs due to its safety features, compact footprint, and curriculum-ready programming interface."

Posted: 5 days ago

"Running 10–50 piece batches daily. The repeatability is outstanding. CNC programs hold tolerance across weeks. Love the gap bed for larger housings."

Posted: 2 weeks ago

"Switched from a single-spindle manual lathe. The twin-spindle feature alone paid for the machine in 4 months. Setup is clean, and maintenance has been minimal."

Posted: 3 weeks ago

"Great hardware. GSK interface works well, but exporting programs takes extra steps. Would love USB or network export in future firmware."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.