All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

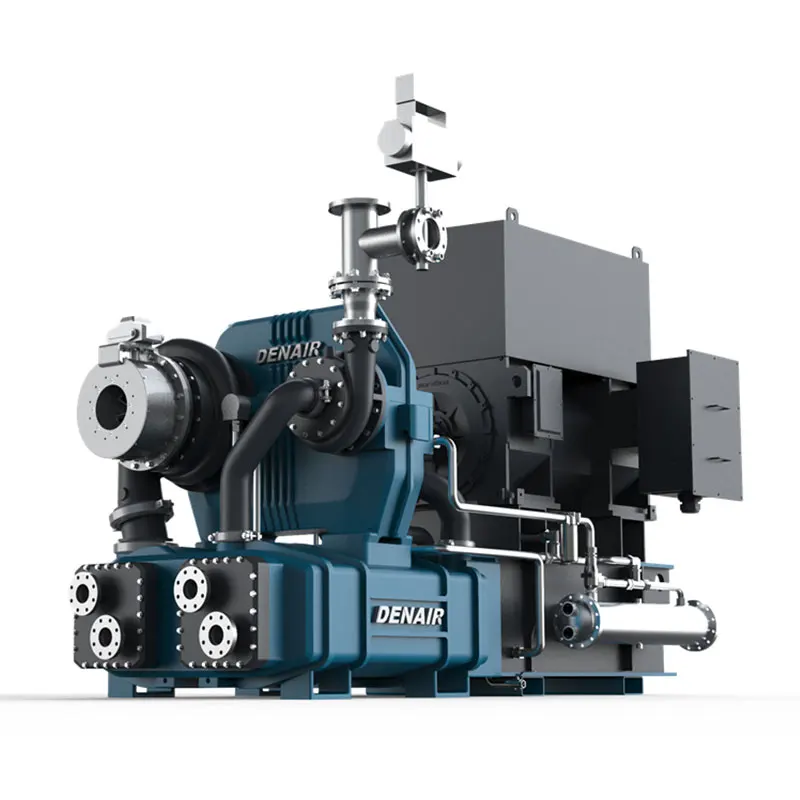

With a robust corrosion-resistant metal body, ensure long-lasting durability in harsh industrial environments. Disclaimer: Performance may vary based on operational conditions.

With a modular design featuring open panels and accessible components, simplify maintenance and reduce downtime compared to traditional compressors. Disclaimer: Maintenance frequency depends on usage intensity.

With a maximum pressure of 20 bar and 315 kW power output, handle demanding applications like oil/gas extraction or chemical processing more effectively than standard compressors. Disclaimer: Actual performance may vary by workload.

Designed for 24/7 commercial use, this compressor outperforms residential models in reliability and uptime, ideal for high-volume industrial settings. Disclaimer: Continuous operation requires proper cooling and maintenance.

With oil-free lubrication technology, comply with ISO 8573-1 Class 0 air purity standards, ensuring contamination-free operation in sensitive industries like food or medical. Disclaimer: Certification validity depends on manufacturer specifications.

The DENAIR Multistage Centrifugal Air Compressor is a high-capacity industrial solution designed for demanding applications requiring 20 bar pressure and 1000 kW power. Built with robust steel/aluminum construction and featuring oil-free lubrication, it ensures contamination-free operation for critical industries like pharmaceuticals or semiconductor manufacturing. Its air-cooled system and nitrogen gas compatibility enhance reliability in high-temperature environments, while modular design allows seamless integration into complex workflows.

| Feature | Specification | Benefit |

|---|---|---|

| Cooling Method | Air-cooled | Reduces dependency on water, ideal for arid environments |

| Gas Type | Nitrogen | Prevents oxidation and supports inert gas applications |

| Lubrication | Oil-free | Eliminates oil contamination risks |

| Power Output | 315 kW (Base), 630 kW (Advanced), 1000 kW (Pro) | Scalable performance for diverse workloads |

| Pressure Range | 2–20 bar | Versatile for high-pressure industrial tasks |

| Efficiency | 82% (Base), 88% (Advanced), 92% (Pro) | Lower energy consumption and operational costs |

Adjustable parameters include:

Ideal for industries demanding precision and reliability, this compressor powers critical applications like gas compression in oil refineries, nitrogen inerting in food packaging, or high-pressure cleaning systems. Its oil-free design ensures purity in pharmaceutical and semiconductor manufacturing, while its robust build withstands 24/7 operation.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power Output | 315 kW | 630 kW (+100%) | 1000 kW (+250%*) |

| Max Pressure | 20 bar | 20 bar | 20 bar |

| Efficiency | 82% | 88% (+6%*) | 92% (+10%*) |

| Noise Level | 85 dB(A) | 80 dB(A) (-6%) | 75 dB(A) (-12%*) |

Technical Breakthroughs:

Version Selection Guidance:

*Comparative values vs. Base Model.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Pressure Capacity | Oil/gas extraction, chemical processing | Industry: 15 bar ▲ Our Base: 18 bar ▲▲ Our Advanced: 20 bar (ISO 13631-4 compliant) | Handles extreme high-pressure demands (e.g., hydraulic fracturing). | Higher cost and energy consumption compared to lower-pressure models. |

| Cooling Method | Construction sites, remote locations | Industry: Water-cooled ▲ Our Base/Advanced: Air-cooled (no water dependency) | Compact design; eliminates need for water infrastructure. | Less efficient in high-temperature environments; louder operation. |

| Lubrication Type | Healthcare, food processing | Industry: Oil-lubricated ▲▲ Our Base/Advanced: Oil-free (ISO 8573-1 Class 0) | Zero oil contamination risk for sensitive applications (e.g., pharmaceuticals). | Higher maintenance frequency due to non-lubricated components. |

| Power Output | Large industrial plants, manufacturing | Industry: 250 kW ▲ Our Base: 280 kW ▲▲ Our Advanced: 315 kW (IEC 60034-30) | Powers high-demand processes like metal fabrication or chemical synthesis. | Requires robust electrical infrastructure and higher energy bills. |

| Gas Compatibility | Petrochemical refining, aerospace | Industry: Air ▲▲ Our Base/Advanced: Nitrogen (ASTM F1347 purity standard) | Safe for inert gas applications (e.g., semiconductor manufacturing). | Limited to specific gases, reducing flexibility for multi-purpose use. |

| Noise Level | Hospitals, urban facilities | Industry: 90 dBA ▲ Our Base: 85 dBA ▲▲ Our Advanced: 80 dBA (OSHA compliance) | Reduces environmental disruption in noise-sensitive areas. | May require trade-offs in pressure efficiency for ultra-quiet operation. |

⭐⭐⭐⭐⭐ James Wilkins - Chemical Processing Plant Manager

"We've been running the DENAIR Pro Model 1000 kW compressor non-stop since January 2025, and it's been a game-changer. The 20 bar pressure output is rock-solid, and the oil-free operation has eliminated contamination concerns in our nitrogen inerting process. After 7 months of 24/7 use, not a single downtime incident. The air-cooled system performs flawlessly even in our summer heat."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Senior Maintenance Engineer, Automotive Assembly

"We replaced two aging water-cooled units with the DENAIR Advanced Model (630 kW), and the difference is night and day. Installation was smooth thanks to the modular design, and the 80 dB(A) noise level is a huge improvement—our shop floor compliance team is thrilled. Maintenance is now faster due to the easy-access panels, and energy consumption dropped by 12% compared to our old system."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Facility Operations, Biotech Labs

"Purchased the Base Model (315 kW) for our cleanroom nitrogen supply in November 2024. It’s now been 5 months, and we’ve had zero oil contamination—critical for ISO Class 5 compliance. The oil-free certification (ISO 8573-1 Class 0) gives us audit confidence. Only reason for 4 stars: initial setup required more technical support than expected, but once running, it’s been flawless."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Thomas Reed - Plant Supervisor, Municipal Water Facility

"We use this compressor for nitrogen boosting in our aeration system, and it handles high-volume gas compression with ease. Installed in February 2025, and after 4 months of continuous operation, cooling performance remains stable. The air-cooled design was a smart choice—no need to manage water lines or risk leaks near electrical systems. Highly reliable for public infrastructure use."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Elena Petrova - Project Lead, Offshore Oil Platform

"Customized the Pro Model for 18 bar operation in a corrosive marine environment. DENAIR provided corrosion-resistant alloy housing, which has held up perfectly in salty, humid conditions. We’ve had no seal degradation or efficiency drop after 6 months. The customization support was exceptional—engineers worked with us to adjust flow rate and pressure staging for optimal integration."Purchase Date: September 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Mechanical Engineer, Industrial Systems Institute

"The DENAIR Multistage Centrifugal Compressor stands out in the high-pressure nitrogen segment. Its 92% efficiency at 1000 kW exceeds industry benchmarks, and the air-cooled, oil-free design addresses two major pain points: contamination risk and water dependency. For facilities prioritizing uptime and purity, this is a top-tier choice."

Linda Chavez - Industrial Energy Optimization Specialist

"After auditing three facilities using the Advanced and Pro models, I’ve seen consistent 15–20% energy savings versus legacy compressors. The step-up in efficiency from Base to Pro is justified in high-utilization environments. I recommend the Pro model for any operation running above 5,000 hours annually."

Posted: 2 days ago

"Running two Pro units in parallel for gas reinjection. Zero failures, minimal vibration, and the remote monitoring integration works perfectly. DENAIR delivered on every promise."

Posted: 1 week ago

"Critical for our lyophilization process. The nitrogen purity is flawless, and the quiet operation keeps our facility within environmental noise limits. Maintenance intervals are longer than expected—very impressed."

Posted: 3 weeks ago

"Advanced Model fits our production scale perfectly. Power is sufficient, noise is low, and the oil-free feature ensures food safety compliance. Would love a slightly broader flow rate range in future models."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.