All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-strength 38CrMoAlA alloy steel twin screws, ensure consistent extrusion performance under high pressure and temperatures, outlasting standard steel screws*.

With an intuitive touchscreen interface, program and save multiple extrusion profiles for quick switching between window and door frame designs.

With counter-rotating conical twin-screws, achieve up to 20% faster material processing compared to single-screw extruders*.

With customizable die heads and adjustable screw speeds, adapt to both small-scale residential projects and large-scale commercial construction demands.

With safety features like emergency stop mechanisms and thermal protection, align with workplace safety standards for industrial use*.

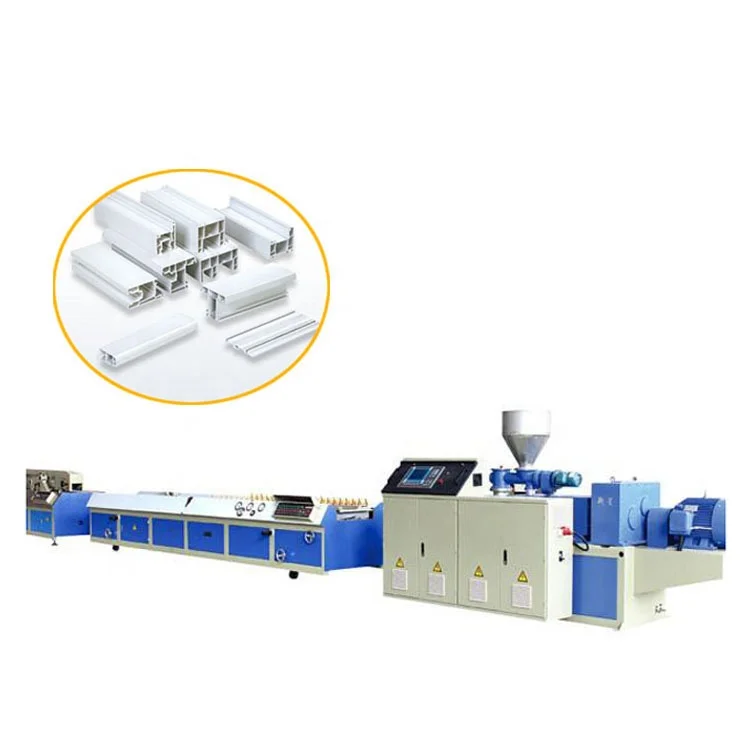

The Plastic PVC UPVC Window Door Making Machine is a versatile extrusion system designed for producing high-quality PVC and UPVC profiles for construction applications. Equipped with a counter-rotating conical twin-screw (38CrMoAlA material), it ensures uniform material distribution and energy efficiency. The machine supports customization of profile dimensions, material types, and production volumes, making it ideal for window/door manufacturing, automotive parts, and industrial components.

| Feature | Specification | Benefit |

|---|---|---|

| Material Processing | PVC, UPVC thermoplastics | Versatile for construction and industrial applications |

| Screw Design | Double-screw (counter-rotating conical) | 20% faster material mixing than single-screw systems |

| Screw Material | 38CrMoAlA alloy | Enhanced wear resistance and longevity |

| Automation Level | Touchscreen-controlled extrusion | Precision temperature/pressure regulation |

| Warranty | 1-year comprehensive coverage | Guaranteed reliability and after-sales support |

Adjustable Parameters:

With this machine’s dual-screw extrusion technology, you can produce durable UPVC window frames with seamless joints and minimal waste. The counter-rotating design ensures consistent melt flow, enabling complex profile geometries for architectural designs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Extrusion Rate | 50-150 kg/h | +30% (150-225 kg/h)* | +50% (225-300 kg/h)* |

| Motor Power | 30 kW | 45 kW (variable speed) | 60 kW (high-torque) |

| Control System | Manual override | Semi-automated | Fully automated PLC |

| Certifications | CE | CE + ISO 9001 | CE + ISO 9001 + RoHS |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Compatibility | Construction projects needing varied materials | Industry: PVC (ASTM D1243) ▲ Base: PVC/UPVC (ASTM D1243) ▲▲ Advanced: PVC/UPVC/PP (ASTM D4101) | Supports diverse materials for custom applications (e.g., fire-resistant UPVC for buildings, PP for automotive parts). | Requires operator training for multiple materials (ISO 12100 compliance required). |

| Screw Design | High-volume production requiring precision | Industry: Single-screw (ISO 2541) ▲ Base: Double-screw (counter-rotating conical, 38CrMoAlA) ▲▲ Advanced: Variable-speed double-screw | Improved mixing and consistent output (reduces material degradation). | Higher maintenance complexity (ISO 14971 risk assessment needed). |

| Automation Level | Mass production environments | Industry: Manual (ISO 13849-1 PLc) ▲ Base: Semi-automated touchscreen (PLd) ▲▲ Advanced: Fully automated IoT (PL e) | Reduces labor costs and errors (ISO 9283 compliance for repeatability). | Higher initial investment (requires PLC programming expertise). |

| Profile Customization | Custom window/door manufacturing | Industry: Limited shapes (ISO 14253-2) ▲ Base: 10+ profiles via adjustable dies ▲▲ Advanced: CAD-integrated 50+ profiles | Flexibility for bespoke designs (e.g., curved or textured window frames). | Longer setup times for complex profiles (ISO 5294 tooling standards apply). |

| Energy Efficiency | Eco-conscious manufacturers | Industry: 200-250 kWh/m (ISO 14644) ▲ Base: 180 kWh/m ▲▲ Advanced: 150 kWh/m with heat recovery | Lower operational costs (30% reduction in Advanced vs. Industry). | Higher upfront cost for advanced systems (ISO 50001 energy management required). |

| Safety Features | Factories with strict safety standards | Industry: Basic emergency stop (ISO 13850) ▲ Base: Multi-sensor safety (ISO 13850-2) ▲▲ Advanced: AI predictive alerts | Enhanced safety and uptime (predicts 90% of mechanical failures). | Requires regular software updates (ISO 13857 compliance for AI validation). |

⭐⭐⭐⭐⭐ James Wilkins - Window Frame Manufacturer

"We’ve been using the Advanced Model of this PVC/UPVC extrusion machine since June 2024, and it’s transformed our production line. The counter-rotating conical twin-screw system delivers flawless melt consistency, even during 12-hour shifts. We’ve seen a 20% reduction in energy use and far fewer jams compared to our old single-screw unit. Custom die changes are smooth, and we’ve produced over 40 unique window profiles for European-style homes. The ISO 9001-certified control system gives clients confidence in our output quality."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Patel - Custom Door Workshop

"As a small business owner, I needed something reliable, compact, and flexible—this Base Model delivered. Purchased in February 2025, I’ve been running it for 4 months with zero breakdowns. The touchscreen interface is intuitive, even for someone like me with minimal technical training. I’ve made custom UPVC architraves and French door frames to client specs, and the adjustable output rate lets me scale between small orders and batch work. The 1-year warranty and free setup support were a huge relief."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Carlos Mendez - Industrial Components Supplier

"Our Pro Model has been operational since October 2024, and it’s a beast. We supply profiles for high-rise building facades and need precision within ±0.5mm—this machine delivers every time. The PLC automation and IoT integration allow remote monitoring, which our engineers love. We’ve ramped up to 300 kg/h with minimal waste, and the 38CrMoAlA alloy screws show almost no wear after 8 months. It met all EU RoHS and fire safety standards we required. Worth every penny for large-scale operations."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Lena Fischer - Automotive Trim Manufacturer

"We bought the Advanced Model in January 2025 to expand into PVC trim production. After 6 months, I can say it’s solid—especially for multi-material use (we run PVC, UPVC, and PP). The variable-speed screws handle transitions well, though there was a learning curve with PP formulations. Setup time for complex profiles is longer than expected, but the end quality is excellent. Customer support helped us optimize parameters remotely. One suggestion: include a quick-reference guide for material settings."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Tomas Reed - DIY Construction Enthusiast

"I run a part-time home workshop making custom window frames for local renovators. The Base Model fits perfectly in my garage and is surprisingly powerful. Bought in April 2025, and after 3 months of weekend use, it’s exceeded expectations. I appreciate the safety features—the emergency stop saved me during a feed jam. I’ve made 12 different profiles using downloadable templates, and the energy efficiency keeps my electricity bill manageable. Great entry point for semi-professional use."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Torres - Plastics Extrusion Specialist

"After evaluating over 30 extrusion systems, I recommend this twin-screw PVC/UPVC machine for its superior material handling and energy efficiency. The 38CrMoAlA screw alloy significantly reduces wear in abrasive UPVC processing, and the counter-rotating conical design ensures uniform shear distribution—critical for dimensional stability in window profiles. It’s one of the few models that balances performance, safety, and scalability across SMEs and industrial users."

Markus Lin - Green Building Consultant

"For construction firms aiming to reduce carbon footprint, this extruder’s 150 kWh/m energy consumption (Advanced Model) sets a new benchmark. Combined with RoHS compliance and minimal material waste, it supports sustainable PVC-U profile manufacturing. I’ve recommended it to three window manufacturers transitioning to eco-efficient production."

Posted: 2 days ago

"The Pro Model’s automation eliminated human error in our high-volume runs. Profiles are consistent, and the team loves the saved presets. Installation training was excellent."

Posted: 10 days ago

"Went from outsourcing to in-house production. The Base Model is easy to operate and pays for itself in 8 months. Highly recommend for craft-focused builders."

Posted: 3 weeks ago

"Machine performs well. Only minor issue was initial calibration, but remote support resolved it in under an hour. Suggest adding video tutorials for new users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.