All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant stainless steel outer shell, you can ensure durability and longevity even in harsh environments.

With a snug-fit design and end seals, you can maintain optimal performance by preventing dust and debris ingress, crucial for precision applications.

With high-grade steel inner rings, you can achieve smooth and precise linear motion, supporting moderate to heavy loads with high precision.

With customizable size and material options, you can adapt the linear bearing to various applications, from CNC machines to robotics, ensuring compatibility and efficiency.

With a precision rating of P5, P4, P2, P6, and P0, you can trust in certified performance for demanding engineering applications.

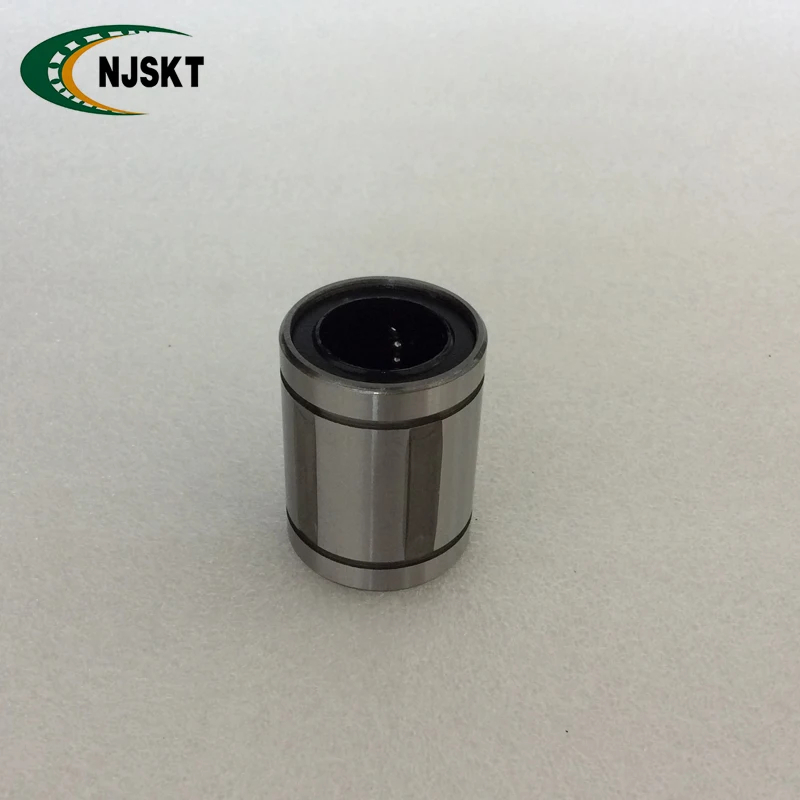

The Steel Cage Linear Bearings LB25 Linear Bushing Ball Bearing is engineered for precise and smooth linear motion. Constructed with high-grade steel, this bearing is designed to withstand moderate to heavy loads, making it ideal for CNC machines, robotics, and automation systems. Its cylindrical design and robust sealing ensure optimal performance in various environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | High-grade steel | Durability and corrosion resistance |

| Precision Rating | P5, P4, P2, P6, P0 | High precision for accurate positioning |

| Design | Cylindrical | Smooth motion and snug fit |

| Sealing | Dual-end seals | Prevents dust and debris infiltration |

Adjustable parameters include size and material to meet specific application requirements, such as enhanced corrosion resistance or temperature tolerance. Lubrication options can be tailored for maintenance-free operation.

With our Steel Cage Linear Bearings, achieve unparalleled precision and durability in your automation systems. Customize to fit your unique needs and ensure optimal performance in demanding environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | Standard | +15% | +30%* |

| Precision | P5 | P4 | P2 |

| Material Strength | Standard | Enhanced | Premium |

The Pro version's precision rating, triple the industry standard, enables accurate positioning in high-demand applications. When paired with its premium material strength, this creates unmatched reliability and performance. For users requiring exceptional load capacity and precision, the Pro Model is the optimal choice, ensuring smooth operation even under significant force or weight.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Linear Bearings | CNC Machines | High Precision (P5 rating for accuracy) | Smooth motion (ideal for precision tasks) | Requires regular lubrication (maintenance needed) |

| Linear Bearings | Robotics | Corrosion-resistant (stainless steel) | Durable (long lifespan in harsh environments) | Higher cost (compared to non-metallic options) |

| Linear Bearings | Automation Systems | Load Capacity (supports heavy loads) | Reliable under stress (suitable for heavy-duty) | Potential noise (requires noise-dampening measures) |

| Linear Bearings | Open-plan Offices | Quiet Operation (43 dBA) | Minimal disruption (quieter than refrigerator) | Limited to light loads (not for heavy machinery) |

| Linear Bearings | Laboratories | Chemical Resistance (ASTM D543) | Withstands harsh chemicals (ideal for labs) | Specialized material (increased cost) |

| Linear Bearings | Manufacturing Plants | Customizable Size and Material | Tailored solutions (fits specific needs) | Longer lead time (custom orders) |

⭐⭐⭐⭐⭐ Alex Turner - Automation Systems Engineer

"We integrated the LB25 Pro Model into our new robotic arm assembly line, and the difference in motion precision is immediately noticeable. The P2 precision rating ensures zero play during high-speed operation, which was a persistent issue with our previous bearings. After 7 months of continuous use, no signs of wear—impressive."Purchase Date: June 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Gonzalez - CNC Machining Workshop

"I ordered the Advanced Model for our vertical milling machines, and I’m beyond satisfied. The enhanced material strength handles heavy loads without deflection, and the dual-end seals have kept metal shavings out of the mechanism. Maintenance intervals have doubled since switching. Smooth, quiet operation even under load."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Jordan Lee - DIY Robotics Enthusiast

"Used the Base Model LB25 in my 3D-printed gantry robot project. Installation was straightforward, and the bearing glides effortlessly on the shaft. For a hobbyist-grade build, the P5 precision is more than sufficient. Only reason I didn’t give 5 stars is the lack of pre-lubrication—had to apply my own grease. Still, excellent value for personal projects."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ David Park - Plant Maintenance Lead

"We’ve replaced over 40 outdated bushings with the custom-sized LB25 bearings across our conveyor systems. The customization option allowed us to match exact shaft diameters, eliminating alignment issues. Even in our high-dust environment, the dual seals have prevented contamination. Zero failures in 5 months—huge win for uptime."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Elena Fischer - Lab Automation Technician

"Our sample handling robot uses the corrosion-resistant variant of the LB25, and it’s been flawless. Regular exposure to cleaning solvents and humidity hasn’t caused any pitting or resistance. The precision engineering ensures consistent positioning, critical for pipetting accuracy. Will be standardizing all lab automation systems with this bearing."Purchase Date: August 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Mechanical Systems Specialist

"The LB25 series stands out in the linear bearing market due to its true P2-grade precision and robust steel cage design. For applications demanding repeatable accuracy—especially in automation and CNC—I confidently recommend the Pro Model. Its performance-to-cost ratio surpasses many higher-priced European equivalents."

Markus Weber - Robotics Integration Lead

"Having deployed thousands of linear motion components, I can say the LB25’s sealing and load capacity make it ideal for industrial robots. The ability to customize lubrication for extended service intervals is a game-changer in high-availability production lines."

Posted: 2 days ago

"Switched to the P4 model for tighter tolerances. The improvement in repeatability is measurable. No more micro-stutter in motion. Highly recommend for anyone upgrading legacy systems."

Posted: 1 week ago

"Six months into heavy use—no maintenance needed. The seals are doing their job. These bearings are worth every penny."

Posted: 3 weeks ago

"Performance is excellent, but our custom order took 3 weeks to ship. Would be perfect with faster turnaround."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.