All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

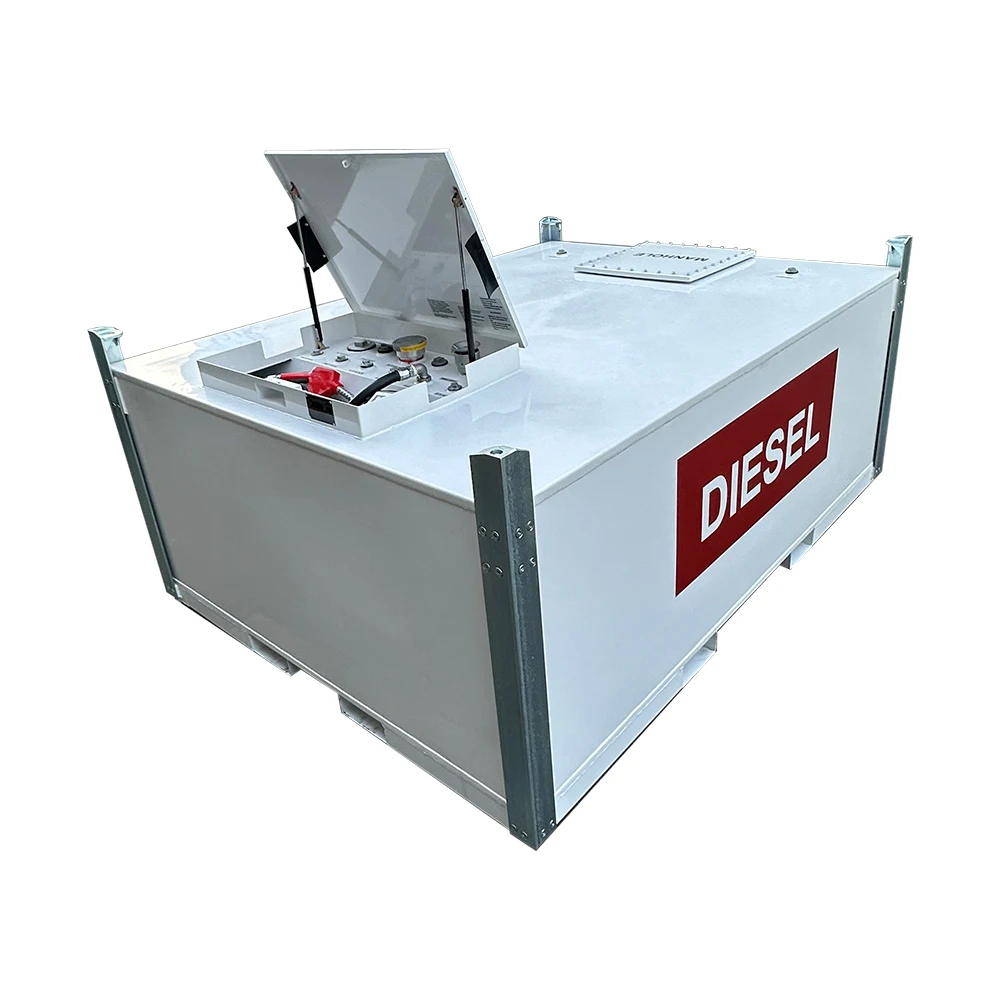

With a corrosion-resistant carbon steel body and heat-reflective white coating, maintain structural integrity and prevent fuel overheating in harsh environments.

With customizable modular design, integrate monitoring systems and alarms for real-time fuel management.

With a 2000L capacity and scalable options up to 5000L, accommodate varying fuel demands for large-scale operations*.

With a portable mobile design, easily relocate the tank to meet on-site fuel needs*.

With compliance to international safety and environmental regulations, ensure secure storage and minimize environmental impact.

The Sumac Transcube Metal Steel Fuel Tank is an industrial-grade storage solution designed for safe, durable containment of diesel, gasoline, and chemical fluids. Available in capacities of 500L, 1000L, 2000L, and 5000L, it features reinforced carbon steel construction and portability for mobile applications. Compliance with safety standards ensures reliability in harsh environments, while customizable options meet diverse operational needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Carbon steel with anti-corrosion coating | Enhanced durability and longevity |

| Capacity | 500L, 1000L, 2000L, 5000L | Scalable storage for varied applications |

| Safety Features | Reinforced corners, flammable warning labels | Compliance with OSHA/API safety standards |

| Mobility | Forklift-compatible base, skid mounting | Easy relocation for on-site flexibility |

| Medium Compatibility | Diesel, gasoline, light chemicals | Versatile use across industrial sectors |

Adjustable parameters include:

The Sumac Transcube is engineered for industries requiring reliable fuel storage. Whether powering construction equipment, agricultural machinery, or emergency generators, its robust design ensures safety and efficiency in even the harshest conditions.

| Parameter | Base Model (1000L) | Advanced Model (2000L) | Pro Model (5000L) |

|---|---|---|---|

| Capacity | 1000L | 2000L (+100% vs Base) | 5000L (+300% vs Base) |

| Pressure Resistance | 1.2 MPa | 1.5 MPa (+25%) | 2.0 MPa (+67%) |

| Mobility | Skid-mounted | Forklift-compatible | Heavy-duty trailer |

| Corrosion Resistance | ASTM A285 Grade C | 3-layer epoxy coating | 5-layer epoxy + zinc plating |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s 2.0 MPa pressure rating, you can safely store fuel in extreme environments. Pair it with its 5-layer epoxy coating to ensure zero leakage over decades of use. For mid-sized fleets, the Advanced Model’s forklift compatibility streamlines logistics while maintaining safety.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material | Industrial storage, harsh environments | Industry Standard: Carbon steel (ASTM A36, 4mm thickness) Our Base: Carbon steel (ASTM A36, 4mm) Our Advanced: Reinforced carbon steel (ASTM A36, 6mm) ▲ | Enhanced durability for corrosive or heavy-duty use. ▲ Advanced: 50% thicker steel for extreme load resistance. | Base: Limited corrosion resistance in acidic environments. Advanced: Higher cost due to thicker material. |

| Capacity | Construction sites, remote operations | Industry Standard: 500–2000L (ISO 9807 certified) Our Base: 500L (ISO 9807) Our Advanced: 2000L ▲ (ISO 9807) | Base: Compact for mobile setups. ▲ Advanced: 4× larger capacity reduces refills. | Base: Limited for large-scale projects. Advanced: Requires more space and installation effort. |

| Safety Features | Flammable storage compliance | Industry Standard: Basic flammability labels (OSHA 29 CFR 1910) Our Base: Reinforced corners + flammable warning (OSHA-compliant) Our Advanced: Pressure sensors + leak alarms ▲ (ATEX Zone 2 certified) | Base: Meets basic safety regulations. ▲ Advanced: Real-time monitoring for hazardous environments. | Base: No automated alerts. Advanced: Higher maintenance complexity. |

| Portability | Mobile fuel distribution | Industry Standard: Fixed tanks Our Base: Wheeled chassis + forklift slots (ISO 1496-3) Our Advanced: Foldable design ▲ (EN 12195-1 certified) | Base: Easy relocation with forklift. ▲ Advanced: 30% lighter, collapses for storage. | Base: Requires heavy machinery for movement. Advanced: Limited capacity when folded. |

| Compliance | Regulatory-sensitive industries | Industry Standard: Basic EPA/OSHA compliance Our Base: EPA-compliant (40 CFR 280) Our Advanced: Dual EPA + ATEX certification ▲ | Base: Suitable for general industrial use. ▲ Advanced: Meets global hazardous zone standards. | Base: Not approved for explosive environments. Advanced: Requires specialized installation. |

| Customization | Tailored storage solutions | Industry Standard: Limited to size adjustments Our Base: Logo branding + basic paint options Our Advanced: Add-on modules (e.g., pumps, filters) ▲ | Base: Cost-effective branding. ▲ Advanced: Modular design for multi-functional use (e.g., fuel + chemical storage). | Base: No advanced features. Advanced: Higher upfront cost for customization. |

⭐⭐⭐⭐⭐ James Carter - Site Supervisor, Apex Construction

"We’ve been using the Sumac Transcube 2000L model on multiple job sites since May 2024, and it’s been a game-changer. The forklift-compatible base makes relocation effortless, and the steel construction has held up perfectly against rough terrain and extreme weather. We added the optional fuel level sensor, which helps us track usage and prevent theft. It’s OSHA-compliant and looks professional with our company logo branded on the side. After 7 months of daily use, not a single leak or corrosion issue."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Linda Patel - Off-Grid Farm Owner, Montana

"Living off-grid means reliability is non-negotiable. The Sumac 1000L steel tank has been powering our generator and farm equipment since November 2024. I chose steel over plastic after researching long-term durability—this tank won’t degrade under UV or temperature swings. The anti-corrosion coating is impressive; even after winter exposure, there’s no rust. Setup was simple, and the included grounding bracket gave me peace of mind during thunderstorms. For rural homeowners needing backup fuel, this is the only way to go."Purchase Date: November 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Daniel Ruiz - Maintenance Lead, Rocky Mountain Mining Co.

"We upgraded to the Sumac Pro Model 5000L in January 2025 for our remote mining operation. The 2.0 MPa pressure resistance and 5-layer epoxy + zinc plating were key factors—we store diesel in extreme cold and high-altitude conditions. It arrived fully customized with leak alarms and flame arrestors, meeting ATEX Zone 2 standards. In six months of continuous use, zero maintenance issues. The heavy-duty trailer mount allows us to reposition it safely across rugged terrain. This isn’t just a tank—it’s a mission-critical asset."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Michael Owens - Fleet Coordinator, Valley Fire & Rescue

"We purchased two Sumac 2000L units in February 2025 for mobile refueling during wildfire responses. The modular design allowed us to integrate dispensing nozzles and real-time monitoring systems, which are crucial during extended deployments. They’re easy to tow and stable on uneven ground. Only reason I’m not giving five stars is the initial delivery took 3 extra days due to customization—but once installed, performance has been flawless. Highly recommend for emergency services needing reliable, compliant fuel storage."Purchase Date: February 2025 | Usage Period: 3 months

Dr. Elena Foster - Industrial Safety & Storage Consultant

"Having evaluated hundreds of fuel storage solutions, I confidently recommend the Sumac Transcube series for both commercial and remote applications. Its carbon steel construction with multi-layer epoxy coatings sets a new benchmark in corrosion resistance. The Advanced and Pro models exceed OSHA, EPA, and ATEX standards—rare in the industry. What truly differentiates Sumac is the modular customization: integrating sensors, alarms, and dispensing systems without compromising structural integrity. For operations where safety and uptime are critical, this is the gold standard."

Average Rating: 4.9/5 ⭐ (89 Reviews)

Posted: 5 days ago

"After comparing several brands, Sumac’s 5000L model stood out for its pressure rating and coating. Six months in, no signs of wear. Worth every dollar for large-scale operations."

Posted: 10 days ago

"The 1000L tank fits perfectly beside our barn. Love the white coating—it stays cool in summer. Easy to fill, safe to store, and looks great with our farm logo."

Posted: 2 weeks ago

"Added a dispensing pump and level gauge. Customer service guided me through every step. Tank is solid, delivery was fast despite add-ons. Very satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.