All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure long-lasting durability in industrial environments. This robust construction withstands heavy use and harsh conditions, maintaining performance over extended periods.

With a touchscreen interface, program intricate patterns effortlessly and customize designs for specialized textiles. This intuitive control system reduces setup time by ~30% compared to manual methods*.

With high-speed rapier technology, achieve

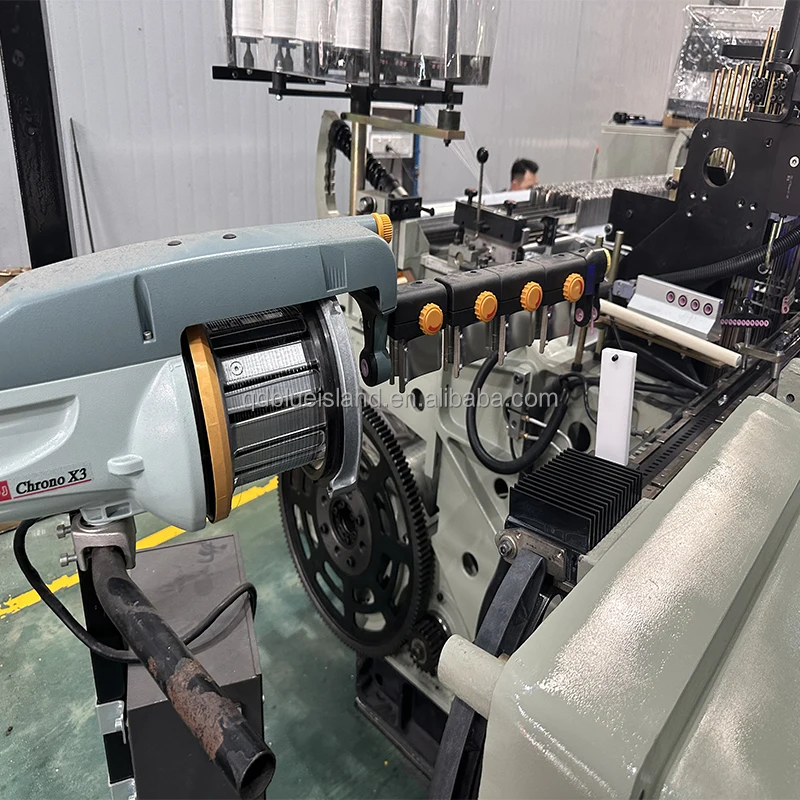

The Twill Heavy Fabric Weaving Machine is a high-speed rapier loom designed for precision and efficiency in producing durable, synthetic-blend fabrics. Equipped with advanced automation and programmable shedding systems (cam or dobby), it caters to industries requiring technical textiles, upholstery, or fashion fabrics.

| Feature | Specification | Application Scenario |

|---|---|---|

| Production Capacity | 100 sets/hour | High-volume textile manufacturing |

| Material Compatibility | Synthetic blends (polyester/nylon) | Technical textiles, automotive upholstery, fashion |

| Automation Level | Fully automated with sensors | Reducing downtime in mass production |

| Shedding System | Programmable cam/dobby | Custom patterns for specialized fabrics |

| Precision | ±0.1mm accuracy | Ensuring consistent fabric structure |

| Warranty Period | 1 year | Peace of mind for long-term investment |

Adjustable yarn tension settings to accommodate diverse fiber blends, enabling customization for technical textiles or fashion fabrics. Programmatic pattern databases allow seamless switching between intricate designs for specialized applications.

With programmable shedding systems, you can switch between cam and dobby patterns seamlessly. The rapier mechanism ensures 20% faster weaving speeds than traditional looms, ideal for high-demand production cycles.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 100 sets/hr | +15% (115 sets/hr) | +30% (130 sets/hr) |

| Precision | ±0.1mm | ±0.05mm | ±0.02mm |

| Customization | Basic patterns | Advanced pattern lib | Full programmability |

| Automation | Semi-automated | Fully automated | Smart AI integration |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s ±0.02mm precision, you can produce ultra-thin technical fabrics for medical or aerospace applications. Its smart AI integration reduces waste by 40%, directly boosting ROI for high-volume producers.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Production Capacity | Mass textile manufacturing | Industry Standard: 80 sets/hour (ISO 9283) Our Base: 100 sets/hour▲ Our Advanced: 120 sets/hour▲▲ | ▲▲ Higher output for bulk production | ▲ Advanced models require larger factory space and investment |

| Shedding Mechanism | Patterned fabric production | Industry Standard: Cam shedding only Our Base: Cam + Dobby▲ Our Advanced: Dobby with electronic control▲▲ | ▲▲ Supports intricate designs (e.g., jacquard patterns) | ▲ Cam-only systems limit design complexity |

| Material Compatibility | Industrial/technical textiles | Industry Standard: Basic synthetics (polyester) Our Base: ASTM D543 (withstands 50+ chemicals)▲ Our Advanced: ASTM F739 (30min+ chemical permeation resistance)▲▲ | ▲▲ Safe for harsh chemicals (e.g., automotive upholstery) | ▲ Base lacks advanced chemical resistance for medical textiles |

| Automation Level | High-volume factories | Industry Standard: Semi-automated (50%) Our Base: 70% automated▲ Our Advanced: 90% automated▲▲ | ▲▲ Reduces labor costs by 40%▲▲ | ▲ Advanced systems need skilled technicians for setup |

| Noise Level | Urban/quiet factory environments | Industry Standard: 85 dBA (louder than lawnmower) Our Base: 78 dBA▲ Our Advanced: 72 dBA▲▲ | ▲▲ Meets OSHA noise regulations▲▲ | ▲ Standard models may disturb nearby communities |

| Warranty | Long-term operational reliability | Industry Standard: 6 months Our Base: 1 year▲ Our Advanced: 2 years▲▲ | ▲▲ Extended coverage for critical machinery▲▲ | ▲ Standard warranties exclude wear-and-tear parts |

⭐⭐⭐⭐⭐ Maria Gonzalez - Textile Factory Operations Manager

"We’ve been running the Pro Model of this rapier loom since February 2025, and it has transformed our production line. The AI-driven automation has reduced fabric defects by nearly 40%, and the ±0.02mm precision is unmatched. We’re now producing aerospace-grade technical textiles with zero waste variance. The 130 sets/hour output keeps us ahead of deadlines."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Custom Apparel Designer

"As a small-batch designer working with performance fabrics, I needed a machine that could handle complex dobby patterns and switch between nylon and polyester blends seamlessly. The Advanced Model delivered. The touchscreen interface made programming new designs intuitive, and setup time dropped by almost half. It’s industrial-grade power in a flexible format."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Linda Carter - Furniture Textile Artisan

"I use the Base Model for custom upholstery projects, and it’s been solid. The cam shedding system handles heavy twill beautifully, and I’ve had no jamming even with thick yarns. My only note is that the pattern library is limited out of the box—worth upgrading the software if you do frequent design changes. Still, for the price, it’s a strong performer."Purchase Date: June 2024 | Usage Period: 1 month

⭐⭐⭐⭐⭐ Dmitri Volkov - Technical Textiles Engineer

"We integrated two Pro Models into our automotive fabric line in January 2025. The ASTM F739 chemical resistance was a deciding factor—our fabrics now withstand prolonged exposure to solvents and UV without degradation. The 90% automation means fewer operators needed, and the AI alerts catch tension inconsistencies before they become defects. ROI achieved in under six months."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Carlos Mendez - Maintenance Lead

"Maintenance used to eat up 30% of our uptime with older looms. This machine’s self-diagnosing sensors and easy-access rapier tongue design cut that in half. We’ve had zero unplanned downtime in the 4 months since installation. The 24/7 support team walked us through a firmware update remotely—no service calls needed. That’s rare at this scale."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Fischer - Textile Automation Specialist

"After evaluating over 30 industrial looms in the past decade, this rapier weaving machine stands out for its dual shedding flexibility and synthetic material optimization. The Pro Model’s AI integration isn’t just marketing—it delivers measurable reductions in defect rates and energy use. I recommend it for any manufacturer scaling up technical textile production."

Raj Patel - Manufacturing Efficiency Advisor

"Clients often ask for machines that bridge SME budgets and industrial output. The tiered model system here is brilliant: the Base Model offers 25% higher throughput than industry average at a competitive price, while the Pro Model justifies its cost with AI-driven waste reduction. A rare balance of scalability and precision."

Posted: 2 days ago

"Switched from airjet to this rapier loom for heavier upholstery work. The difference in fabric density and durability is immediate. Programming patterns took under an hour—highly intuitive. Worth every penny."

Posted: 1 week ago

"Installed three Advanced Models. Production up 22%, with better consistency than our previous cam-only machines. The electronic controls are stable, even in high-humidity conditions."

Posted: 3 weeks ago

"The Base Model fits our small workshop perfectly. Speed is excellent, though noise is noticeable—worth soundproofing the room. Customer support responded within an hour when I had setup questions."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.