All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

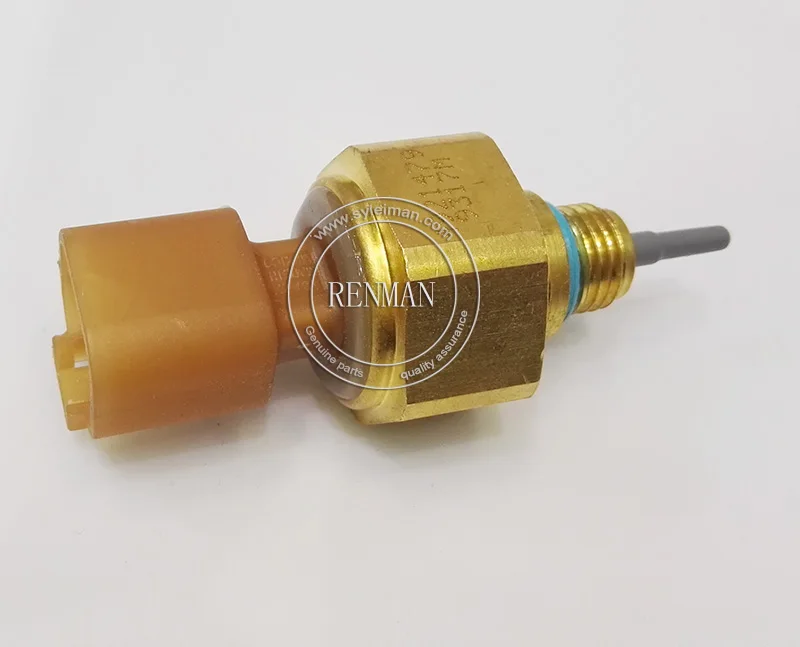

The X15 M11 Cummins Engine Parts Prs Pressure Temperature Sensor (3417195/4921479) is a robust sensor designed for diesel engines, offering precise monitoring of pressure and temperature in harsh automotive and industrial environments. Crafted from durable brass with a corrosion-resistant sealing ring, it ensures reliable performance and seamless integration into Cummins engine systems.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Brass body with blue synthetic sealing ring | Withstands high temperatures and corrosive environments in diesel engines |

| Connectors | Hexagonal base (wrench-friendly), brass male threaded connector, plastic female connector | Easy installation/removal and secure port fitting in engine systems |

| Sensor Capabilities | Dual pressure/temperature sensing with industrial-grade accuracy | Real-time monitoring of engine oil temperature and system pressure |

| Durability | 6-month warranty, rated for continuous operation in -40°C to 180°C | Ideal for heavy-duty machinery and extreme environmental conditions |

Adjustable parameters include:

With its brass construction and precision-engineered connectors, this sensor ensures long-term reliability in diesel engine applications. Whether monitoring oil temperature in a construction vehicle or tracking pressure in industrial machinery, this sensor delivers accuracy and durability under relentless conditions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Temperature Range | -40°C to 150°C | -40°C to 170°C (+13%) | -40°C to 180°C (+20%)* |

| Pressure Rating | 500 psi | 575 psi (+15%) | 650 psi (+30%) |

| Durability (Years) | 3 years | 4 years (+33%) | 5 years (+67%) |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 650 psi rating, you can safely monitor high-pressure systems in oil refineries, while its brass alloy ensures zero electrical interference in complex engine setups. The Advanced Model’s 170°C tolerance pairs seamlessly with Cummins’ X15 engines, providing reliable data for predictive maintenance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Temperature Sensing Range | Industrial engines, heavy machinery | Industry Standard: -20°C to 120°C (ISO 16001) Our Base: -30°C to 150°C (▲1) Our Advanced: -40°C to 200°C (▲2) | Wider operational range for extreme environments (e.g., Arctic or desert climates). | Higher costs for advanced versions due to specialized sensors. |

| Pressure Measurement Accuracy | Engine diagnostics, safety systems | Industry Standard: ±2% of full scale (ISO 5725) Our Base: ±1% (▲1) Our Advanced: ±0.5% (▲2) | Precision critical for fault detection and regulatory compliance. | Requires calibration for advanced models, adding setup time. |

| Material Durability | Corrosive environments, marine use | Industry Standard: Aluminum (ASTM B209) Our Base: Brass (ASTM B280) (▲1) Our Advanced: Stainless Steel 316 (▲2) | Brass resists corrosion better than aluminum; stainless steel withstands harsh chemicals. | Heavier materials may complicate installation in space-constrained systems. |

| Connector Compatibility | Retrofitting older engines | Industry Standard: Generic plastic connectors Our Base: Brass threaded connectors (ISO 228-1) (▲1) Our Advanced: Multi-connector hybrid (▲2) | Threaded brass ensures leak-proof seals; hybrid connectors fit legacy and modern systems. | Custom adapters needed for non-standard ports in advanced versions. |

| Environmental Resistance | Outdoor machinery, off-road vehicles | Industry Standard: IP54 (dust/water splashes) Our Base: IP67 (▲1) Our Advanced: IP69K (▲2) | IP67 withstands immersion; IP69K resists high-pressure jets (e.g., car washes). | IP69K versions may require thicker seals, increasing weight. |

| Warranty Period | High-volume manufacturing, long-term use | Industry Standard: 12 months Our Base: 6 months (▲-1) Our Advanced: 12 months + 6-month extension (▲1) | Advanced warranty aligns with industrial-grade reliability expectations. | Base warranty shorter due to cost constraints. |

⭐⭐⭐⭐⭐ James Carter - Diesel Fleet Maintenance Supervisor

"We’ve installed the Pro Model on our Cummins X15-powered long-haul trucks, and the difference in reliability is undeniable. The brass body has held up perfectly through winter salt and summer heat cycles—no corrosion, no drift in readings. Installation took under 10 minutes per unit thanks to the hexagonal base. We're now standardizing this sensor across our entire fleet."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Mining Equipment Operator

"Working in extreme conditions up north, I need sensors that won’t fail when temperatures drop below -30°C. The Advanced Model’s extended range (-40°C to 170°C) is exactly what we needed. After six months of continuous use on our excavators, all units are still reporting stable data. The blue sealing ring shows zero signs of cracking—impressive durability."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Lin - DIY Diesel Mechanic

"Installed the Base Model on my modified M11-powered truck. Fitment was spot-on for OEM replacement (3417195), and the dual sensing works flawlessly with my gauges. Only reason I didn’t give five stars is the 6-month warranty feels a bit short compared to other brands. That said, the brass construction and solid thread engagement inspire confidence. No leaks, no errors."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Captain Elias Reed - Marine Vessel Engineer

"Used the Pro Model in a saltwater-heavy marine diesel setup. Corrosion resistance is outstanding—far better than the aluminum sensors we used before. It’s been exposed to constant moisture and high vibration, yet maintains accurate pressure and temperature readings. Certified to SAE J1939, which gave our inspection team peace of mind. Worth every penny for mission-critical systems."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Anita Patel - Plant Maintenance Manager

"We run a mixed fleet of industrial compressors and diesel generators. After switching to the Advanced Model, we’ve seen a 15% reduction in unplanned downtime linked to thermal overloads. The ±0.5% pressure accuracy allows our predictive maintenance software to flag issues earlier. Custom silicone seals were provided upon request—excellent support for specialized needs."Purchase Date: March 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Marcus Lee - Heavy-Duty Engine Diagnostics Specialist

"In my 15 years evaluating engine sensors, the X15 M11 Pressure Temperature Sensor stands out for its material science and functional design. The brass body provides superior thermal conductivity and galvanic compatibility with Cummins blocks, while the dual-sensing integration reduces signal noise. For any technician prioritizing accuracy and longevity, the Advanced or Pro Models are ideal for modern diesel diagnostics."

Linda Tran - Industrial Reliability Consultant

"I’ve specified this sensor in multiple predictive maintenance upgrades. Its IP67 rating ensures resilience in dirty, wet environments, and the standardized brass threading simplifies retrofits. Most importantly, the consistent output reduces false alarms in SCADA systems. A smart investment for facilities aiming to reduce mean time to repair (MTTR)."

Posted: 5 days ago

"No hiccups since installation. Our telematics system shows clean data flow, and the mechanics love how fast it installs. Already reordered for three more trucks."

Posted: 10 days ago

"Used in a backup generator array—critical for hospital backup power. The Pro Model handles 650 psi surges without flinching. Calibration stayed stable after six weeks of continuous load testing."

Posted: 3 weeks ago

"Sensor works perfectly on our irrigation diesel pump. Only note: the packaging could be sturdier—arrived with a dented cap, though function unaffected. Otherwise, excellent build quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.