All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1136 products available)

The 12V off delay timer is an electronic device applied to control the switching off of an electrical system after a certain preset time when power off conditions are in effect. These timers are widely used in industrial automation, HVAC systems, and other applications where controlled delay switching is required. Delay timers usually have a few typical features, such as adjustable time intervals, various output configurations, and robustness in different environments.

The ON delay timer switches the output after a preset time interval corresponding to the application of the input signal. For instance, when a device receives power, the timer begins its preprogrammed sequence, and only after the elapse of the set time does the output switch on, thus facilitating smooth transitions needed in processes. Common usages of ON delay timers typically include equipment startups wherein systems need to power up gradually, thus preventing possible mechanical stresses in the system.

The OFF delay timer operates differently by switching the output off after a preset time once the input condition is off. Meaning that when an associated device or system is switched off, this timer continues running its predetermined schedule, thus allowing the initial system outputs to remain active temporarily. This feature is especially useful in processes where safeguards or equipment de-escalation are required after the completion of tasks. Industries herein often utilize OFF delay timers, such as production cut-offs that need a sequence to follow for safety and equipment integrity.

However, the cyclic timer resets the output at programmed time intervals with the elapse of a defined duration of the output cycle. Such timers are used in applications that need constant activating and deactivating within a time frame. In this case, several industries use cyclic timers to automate processes such as production lines to maintain efficiency and reduce human intervention.

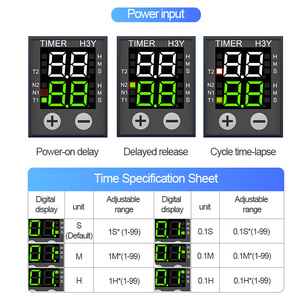

The adjustment of time intervals on most off delay timers usually ranges from a few seconds to some minutes or hours. Thus, the users must get the required settings for their respective applications since most settings are adjusted using small knobs or buttons. It is also necessary to note that the timer may use varying increments of time depending on the model, thus adding flexibility. In this respect, maintenance entails regular checks and calibrations to ensure the time settings are precise and the users are serviced accordingly.

The power supply indicates that the 12V off delay timer operates at low voltage, requiring stable voltage levels for precise functioning. In other words, variations in voltage can lead to erratic behavior or malfunctioning of the device. Maintenance checks include verifying that the attached power sources are in good working order and, on top of that, ensuring connections are secure to minimize voltage drops.

Since most delay timers are used in industries, their contacts control some heavy electrical loads. These are the most common information as Normally Open (NO) and Normally Closed (NC) specifications that are standardized, but users should be aware of and avoid wear on contact. Maintenance work consists of frequent inspections for signs of burning or welding to prevent equipment failure. Moreover, with some modern timers, one can eliminate contact wear by using solid-state outputs.

The enclosure specifications indicate that many off delay timers come in either standard or IP-rated enclosures for protection against dust or moisture. In other words, users working in hostile environments should ensure that their timer is improperly enclosed so that it can resist environmental stresses. Checking the integrity of the timer's house can prevent such incidences as exposure to internal damage components and, therefore, no interruptions in functioning.

Compatibility with other devices indicates that off delay timers are usually equipped with extra features such as sensors, switches, or programmable logic controllers (PLCs). Those features that help integrate with other systems can improve maintenance since it causes the connected devices to have more checks to ensure the system is running smoothly. Plus, timers can only be used effectively if the users ensure that the maintenance of these associated components is done properly.

One common commercial use of 12V off delay timers is to control lighting systems within buildings. When these sensors detect occupancy, the timers allow lights to stay on for a specific period, so if a room is empty, the lights switch off after a set timing. This not only saves energy but also lowers costs while at the same time improving the efficiency of the building's operations.

HVAC systems are another area wherein the 12V off delay timer is used frequently. These timers help in controlling the operation of heating, ventilation, and air conditioning systems by ensuring that the components such as fans or compressors continue to run for a preset time after the system is switched off. In this way, it allows for the proper circulation of air and eliminates the possibility of overheating, thus maintaining efficiency and prolonging the life of the equipment.

Off delay timers have also been used in refrigeration systems such as commercial food storage displays, freezers, and refrigerators. Here, when power is lost or the door opened for some time, the off delay timer allows the system to continue operating for a set period. This helps maintain temperature and reduce product spoilage. Users have also prevented spoilage by using freezers or refrigerators during short power outages; therefore, the product's quality and safety is ensured.

Automatic teller machines (ATM) are examples of electronic devices where 12V off delay timers are applied. In this case, the timer controls various operations like dispensing cash, printing receipts, or switching on/off the display after customer interaction. Time management in these processes leads to better customer satisfaction and operational efficiency.

Finally, 12V off delay timers control the automatic irrigation systems used in agriculture and landscaping. Depending on the weather conditions, these timers ensure that water is delivered for the crops or landscaped areas for a specific duration and switched off after some preset time. This not only conserves water but also provides optimal conditions for growth, increasing agricultural efficiency.

The first thing a buyer needs to do is identify the application needs. Different systems require different off delay timers, so common cases a timer turns off after a certain period of time. Again, consider how long the timer should work, what loads it should handle, and other environmental concerns it may face.

Adjustability of the time interval has also to be considered since some applications need specific delays, while others can work with a broader range. If flexibility is essential, go for a timer that can range from a few seconds to several minutes or even hours. This feature allows users to adapt the system to changing requirements without necessarily replacing the device.

In the selection of the output type, 12V off delay timers usually come with several output options, such as relays or solid-state. Relay outputs are generally preferred for handling heavy electrical loads because they have mechanical wear components, which can be a concern in heavy operations. On the other hand, solid-state outputs provide a longer operating life and have less maintenance but can handle smaller loads only suitable for light loads.

Environmental resistance indicates that certain applications expose components to dust, moisture, or extreme temperatures. In such cases, ensure that a 12V off delay timer has an IP-rated enclosure for better protection or is designed for extra durability in hostile environments. This aspect will impact the reliability and longevity of the device significantly.

Lastly, it is important to check the compatibility of other systems or components. Many 12V off delay timers can be integrated into PLCs and other automation devices for more complex control systems. If the users are working within a system that requires broader control, go for a timer easy to integrate into the existing setup. This will help enhance operational efficiency due to better coordination among the components.

A1: The 12v off delay timer is an electronic device used to control the switching off of a system. It does this by setting a time period after power is lost before the system completely switches off. This is helpful in processes that need the system to stay on for a short time.

A2: Off delay means the time it takes for the output to stop after the input has stopped. For example, after an easy task is done, off delay gives extra time before everything shuts down completely.

A3: Off-delay timers are used in many places. These include buildings to save energy, machines that heat or cool air, and refrigerators at stores to keep food safe. They help automate processes and improve efficiency. They are especially useful for controlling lights and cooling systems.

A4: Off-delay timers work through light sensors. They keep the lights on when they detect people in the room. If no one is detected for a set period, the timer turns the lights off automatically. This helps save energy by ensuring lights are not left on in empty spaces.

A5: Off-delay timers help improve the efficiency of heating, cooling, and ventilation (HVAC) systems). They ensure that air fans or cooling parts keep working for a little time even after the system is turned off. This helps move air around and cools parts down properly.

A6: Yes, off-delay timers help protect important machines. They stop constant starting and stopping, which can wear out parts fast. They give each machine some time to finish its job before shutting down completely. This helps machines last longer and stay in good working order.

A7: Off-delay timers stop all output after the input signal stops. On-delay timers start the output a short time after receiving the input signal. So off-delay stops tasks slowly and smoothly, while on-delay starts them up slowly.

A8: A cyclic timer switches outputs repeatedly at set time intervals. It automates tasks like turning lights on and off regularly without manual help each time.