All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(948 products available)

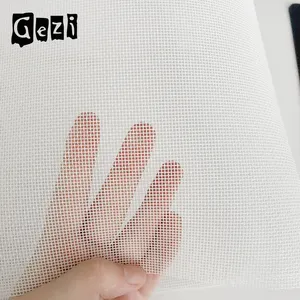

15d nylon mesh fabric is a premium-quality, lightweight, and versatile textile. It finds application in numerous fields. Below are the most common types based on structure, purpose, and weave.

Standard Nylon Mesh

Regarding everyday use, this is the most popular type of nylon mesh. It is suitable for garment ventilation and soft gear storage. 15d nylon provides an excellent balance between tensile strength and breathability. This makes it desirable for applications in athletic wear and outdoor gear. The fine 15d threads give it a very soft touch and a transparent look.

Ripstop Nylon Mesh

This variety is woven with a particular technique that includes reinforcing threads at spaced intervals. This forms a 'ripstop' structure that is exceptionally resistant to tearing. When 15d nylon is combined with the ripstop weave, users get a super-light mesh that can stand up to great challenges. It performs particularly well in ultra-light camping gear, parachutes, and racing kites. These are the constantly stretched or at risk of tearing fabrics.

Coated Nylon Mesh

A coating is usually added to the base nylon mesh to improve water resistance, durability, and strength. This may include polyurethane (PU) or polyvinyl chloride (PVC). 15d coated nylon mesh makes a fabric that is highly useful in moisture-sensitive applications. These include premium outdoor gear, medical bags, and protective clothing where extra resistance is required.

Hydrophobic Nylon Mesh

This type is engineered to resist water absorption, hence drying faster than ordinary nylon meshes. Hydrophobic nylon is particularly applicable in athletic and military gear. This is because the material quickly wicks away water from the surface. Light 15d mesh enhances functional performance without adding extra weight.

Porous Nylon Mesh

This weaved nylon mesh is custom-made for lightweight and breathable qualities. It has various holes of differing dimensions throughout its structure. It is mainly utilized in medicals contexts. These include filters, screens, and other medical devices requiring air circulation while retaining sterile liquid barriers. It is super easy to clean or autoclave.

Custom-Weave Nylon Mesh

This offers flexibility in design for custom applications. They can modify the weave pattern, density, and twill to fit specific industrial needs. For instance, tighter weaves can ensure higher durability. On the other hand, looser weaves improve flexibility and breathability where suitable.

15d nylon mesh fabric has several key features that enhance its usability and appeal across a variety of industries and applications. Here are some of its main features, as discussed below:

Lightweight

15d nylon mesh is one of the most ultra-lightweight threads. This makes it super easy to carry, compact, and exceptionally versatile. Users can stretch or pack it without extra stress or space problems. Because of its lightness, it finds homes in outdoor apparel, and geese become lighter to carry.

Durability

Though 15d nylon is extremely fine, it is still strong enough to withstand abrasions. In a physical sense, abrasion is the process of scraping or wearing something away. This quality makes it ideal for uses that require long-lasting resistance to wear, be it in commercial or independent settings. Therefore, it is extremely popular in the production of sports and camping gear.

Breathability

The mesh structure allows for airflow through the fabric. This keeps the body cool and enables garment moisture to evaporate. This makes it a commonly used feature in athletic clothing and outdoor tents. In such scenarios, comfort and a cooling factor are vital.

Versatility

15d nylon mesh gets used in many different fields. These include apparel, outdoor gear, industrial applications, and medical devices. Its adaptability makes it a popular choice when lightweight and durable materials are necessary for several functions.

Stretch and Flexibility

The material can also bend or move without breaking or losing its integrity. This flexibility adds to the comfort of garments, particularly in performance wear where movement is key. Moreover, the degree of stretch also varies by the specific weave. Usually, tighter weaves offer limited stretch, while looser weaves allow greater movement.

Water Resistance

Water resistance mainly comes into play when using coated 15d nylon mesh. These coats typically include polyurethane or PVC. Though the mesh is light, it can repel moisture. This is an excellent characteristic for outdoor gear like tents, backpacks, and rainwear where extra protection from the elements is vital.

Easy to Clean

The fabric is machine washable for easy cleaning and maintenance. Users can easily remove dirt, stains, or sweat without impacting the material's integrity. Lastly, this further increases the item's usable life and efficiency.

Various customization options exist for businesses and manufacturers to keep meeting specific project goals. For quick reference, here is a list of some of the most popular customization options available for the 15d nylon mesh fabric:

Color Customization

To achieve brand concealment, manufacturers have to dye the mesh fabric to any color preferred. This is especially useful for sporting or military applications, where blending with the environment may be important.

Printing

Business owners can screen print or employ digital printing techniques to place logos, patterns, or other designs on the fabric surface. These prints are durable enough to withstand extreme weather conditions.

Coating Options

Manufacturers normally add PU or PVC coatings to the nylon mesh according to the end usage. Coating can modify elements like water resistance, durability, and texture. PU coatings improve flexibility and make the material more water-resistant. On the other hand, PVC coatings enhance wear and tear resistance. This gives the mesh longer life. People also want coatings with specific properties, such as anti-microbial or UV protection.

Custom Weave Patterns

Depending on the required strength, breathability, or elasticity, businesses can now alter the weave pattern of the nylon mesh. Tighter weaves mean more strength and less stretch. Conversely, looser weaves mean more airflow and flexibility. This custom option is critical in fine-tuning mesh to meet particular industrial requirements.

Size and Shape Specifications

Manufacturers generally produce nylon mesh in various widths, lengths, and thicknesses. This lets them accommodate projects requiring particular dimension specifications. Customers place either order with predetermined size customizations.

Fraying Prevention Edges

Further modifications, like sewing or heat sealing the edges of the mesh, will prevent fraying. This ensures long-term security, especially in gear or garments that experience constant movement and wear.

Short Lead Times

It is important to note that modern-day customization processes strive to achieve quicker lead times without compromising on quality. Advances in technology, alongside better management of resources, enable manufacturers to fulfill bespoke orders in timely manners, further enhancing usability.

15d nylon mesh fabric has numerous practical applications across various industries. They utilize its lightness, strength, and adaptability. Below are some of the most popular applications for 15d nylon mesh fabric:

Outdoor Gear and Equipment

Since 15d nylon mesh fabrics are so lightweight, mountaineers use them to make tents, backpacks, and sleeping bags. The fabrics are breathable and allow airflow. This feature prevents condensation within the tent and helps food or gear inside the bag dry quickly. Therefore, nylon mesh is a staple for outdoor enthusiasts and manufacturers who seek to make innovative lightweight gear for adventurous seekers.

Sports Apparel

Sports attires incorporate these nylon meshes. Athletes benefit from the breathability and ventilation, as they help the garments allow body air. 15d nylon is super-soft and hardly feels like an extra layer of clothing. Enthusiasts use it to manufacture running shirts, workout tights, and jerseys.

Medical Applications

Companies also prefer 15d nylon mesh in medical devices. Such devices include surgical implants and prosthetics. Its strength, lightness, and biocompatibility make it a desirable material for internal and external uses requiring strength without mass. People use it in wound dressings or mesh for tissue repair and support. Usually, repair and support require materials that are unlikely to be affected by environmental factors, such as moisture. In addition, 15d nylon is autoclave-compatible. This makes it easy to sterilize for critical uses.

Industrial Filters and Screens

Industrially, 15d nylon mesh fabric makes fine sieves and filters. This is simply because its porosity is adjustable to capture various particle sizes. Moreover, it is corrosion-resistant to most chemicals, which increases its lifespan. Therefore, industries like water treatment, aerospace, and manufacturing find it an extremely versatile mesh. In most applications, it is vital to ensure purity and mechanical reliability.

Aquaculture and Agriculture

The mesh helps farmers with crop protection and pest control. Its lightweight allows air and sunlight to pass through while keeping larger insects and birds out. Fish farmers also put up these meshes in their fish farming practices. The mesh comes in handy in creating screens for broodstock separation or protection in aquaculture systems.

Home and Fashion Accessories

People widely use this fabric in several personal possessions because of its appeal and practicality. Designers prefer it for sunglasses cases, and the bags are light yet sturdy. Thus, nylon mesh makes stylish and functional items. Mesh panels in clothing add aesthetic value and ventilation. Lastly, it is well-sought after by sports and fashion professionals due to its contemporary feel and practicality.

Selecting the correct material means considering several important factors. Buyers should think about these factors carefully so that everyone can enjoy the wonderful versatility and performance of the mesh fabric. Here is a helpful checklist for making the right choice for various uses:

Weaving

The weaving technique used when making the nylon mesh is crucial because it can affect both the durability and flexibility of the material. Tighter weaves allow little to no stretch and increase the fabric's strength. On the other hand, looser weaves do allow more airflow and flexibility. Therefore, buyers' intended use should largely rule the choice of weave.

Coatings

Besides, buyers should consider whether the nylon mesh needs a coating or not. Coated meshes, such as those with a PU or PVC layer, increase the fabric's water-resistant and durability qualities. This makes it good for outdoor uses. Uncoated meshes are more breathable. They are also softer and tend to be lighter. Users need them for high-performance apparel or ventilated gear.

Mesh Density and Hole Size

Both these features affect the fabric's breathability and strength. Greater mesh density means a greater number of threads per inch and a tighter weave. This results in a more robust and more solid material. Conversely, larger holes lead to more airflow and flexibility but less filtering capability. Customers looking to use the mesh in apparel or outdoor gear should weigh the importance of breathability versus strength before making the final choice.

Finish and Treatment Options

Manufacturers can apply diverse finishes and treatments to nylon mesh fabrics to enhance specific properties. For instance, anti-microbial treatments improve hygiene and lengthen the mesh's usable life. Conversely, UV-resistant finishes increase the mesh's dwell time outdoors while being exposed to harsh conditions.

Application Needs

Buyers always consider mesh fabric's specific application requirements. For instance, a lighter mesh is preferable in fashion and home furnishings. In industrial filtration or medical applications, more robust and durable mesh is ideal.

Testing and Samples

Reasonably requesting fabric samples is one surefire way to test mesh performance. Customers will feel and assess the quality of nylon. They will also verify whether it meets their functional and aesthetic standards before placing an order for bulk supplies.

A1: This is a lightweight, durable, and extremely versatile fabric. Most importantly, it allows air and water to pass through. Manufacturers create it from fine nylon threads that have superior strength and flexibility properties.

A2: Companies and manufacturers commonly use this versatile fabric in a wide range of applications. Practically, they use it in outdoor gear such as tents and backpacks for breathability and weight-saving purposes. They also use it for industrial filtration, medical devices, and sports apparel for strength and longevity.

A3: Nylon mesh offers quite a number of benefits to its users. Some of them include breathability, lightness, strength, and versatility. The fabric is super breathable. This keeps wearers cool and dry. Its lightness makes it easy to carry around or wear. Lastly, its durability ensures it can withstand wear and tear for extended periods even in rigorous conditions.

A4: Though nylon is a synthetic material, it can be recycled. Recycling 15D nylon mesh fabric can contribute to reduced environmental impacts. Therefore, there are ongoing innovations in the production and recycling processes that help make nylon a more environmentally responsible option over time.

A5: Customers can simply wash this fabric by hand in cold water using mild soap. They can machine wash it on a gentle cycle with cold water, too. They should air dry it in the shade to prevent UV degradation and maintain its strength.