All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1197 products available)

A 3-volt servo motor is a small motor that helps control the position of something. It runs on just three volts of electricity, which is a bit like a small battery. These motors are often used in remote control cars, robots, and even tiny airplanes to move parts, like wheels or arms, to the right spot. Because they use so little power, they’re great for smaller machines that help with simple tasks.

The types are:

RC servo motor

An RC servo motor is a small, precise motor used in remote-controlled cars, planes, and robots to move parts like wheels or arms. It can turn to a set position quickly and accurately, which is great for keeping things steady in a game or a model. The motor is powered by a battery and controlled by signals from a simple remote or a little computer. This helps the motor move the parts in the right direction and at the right speed, making the toys and models work better and last longer.

Continuous rotation servo

A continuous rotation servo motor can spin all the way around, unlike some that only turn a little bit. It can go forwards and backward, which helps things like wheels on a robot move in any direction. This motor is controlled by a battery and a tiny computer that sends it signals to spin fast or slow. The features of this servo are good for simple tasks like moving belts or fans, but not for tiny, careful movements.

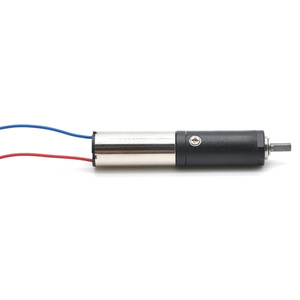

Gearbox servo motors

Gearbox servo motors use gears to make the motor stronger, which helps with heavy jobs. The gears make the turns smaller, giving more force to move big things, like a conveyor belt. This motor is powered by a battery and the movement is controlled by a little computer that manages the signals. Gearbox servo motors are widely used in industries to move and lift heavy objects or machinery parts.

Traxxas servo motor

A Traxxas servo motor is a special part that helps move the wheels or other parts in radio-controlled cars made by Traxxas. It makes the steering work smoothly and can handle bumps or rough driving. When the remote control is used, the motor moves the steering and keeps it steady, even on tough tracks. Traxxas servo motors help RC cars steer better and last longer on hard or bumpy paths.

Brushless servo motor

A brushless servo motor is a type of motor with good control over its speed and position. It doesn't have brushes inside, which makes it last longer and work better. It provides smooth, silent operation, which makes it ideal for sectors like robotics and CNC machines, which need fine movements. Because it works well and doesn't wear out fast, it's great for use in machines that must keep going for a long time.

3v dc servo motors are commonly used because they provide accuracy and control in many mechanical processes. These motors are mainly used in systems where precise control of speed, position, and torque is required.

Automated mechanical systems

Mini servo motors are used to control the movements of mechanical parts in an automated system. This guarantees the right assembly of components, enhancing speed and efficiency in production lines. Basically, these motors are used for the automation of mechanical systems in industries.

Textile machinery

Servo motors provide precise control of fabric movements in the textile industry. This helps in the accurate weaving and sewing of fabrics. Basically, these motors help in controlling the movement of fabric in textile machinery.

Printing presses

In printing presses, servo motors control paper movement and ink distribution. This ensures high-quality print output with accurate color and detail. Basically, the motors control the movement of paper and the distribution of ink in printing presses.

Robotic arms

In industries, servo motors provide precise control over the movements of robotic arms. As a result, it enables intricate assembly and manipulation tasks. Basically, these motors control the movements of robotic arms in manufacturing.

Packaging machinery

3v servo motors are used in packaging machines to control bag fillers, label applicators, and sealers. This ensures accuracy and speed in the packaging process. In addition, these motors control the movement of different components in packaging machinery.

Nominal voltage

The 3v input for a servo motor means it works best on a 3-volt power source. Most motors are able to work on a small range of voltages around the nominal voltage and, therefore, a little variation is acceptable. However, applying too high or low a voltage can cause problems such as overheating, slow functioning, or even damage.

Torque

Torque measures how much weight a servo motor can handle while turning. For instance, a motor with 5 ounces of torque can lift 5 ounces of weight at 1 foot up or out. If the weight goes higher or further, the motor must have more torque to keep turning properly. In simple terms, higher numbers are stronger and better for hard jobs.

Speed

Motor speed is how fast the motor turns its output shaft. It is measured in revolutions per minute (RPM). This means how many turns it does in one minute. Higher speeds allow faster operations. However, this must be balanced with torque because faster motors can handle less really heavy stuff. The right speed makes sure it does its job quickly without dropping anything heavy.

Stall conditions

Stall is an important aspect of a servo motor because it shows the limits. When the load is greater than the stall torque, the motor stops. This can lead to heating or damage. Therefore, stall torque should be avoided in applications. Appropriate loads must be used to avoid reaching the stall torque.

Motor type

There are two main types of servo motors: brushed and brushless. Brushed motors are simple and cost-effective, suited for applications where precise control is not critical. Brushless motors, on the other hand, provide greater efficiency, longer life, and require less maintenance. This makes them ideal for high-performance applications, in which the motor type plays a significant role in the motor's reliability and efficiency.

Current rating

A current rating tells how much electric current the motor uses to operate correctly. Different motors use different amounts of current, depending on the tasks they perform. Low-power motors use a small current, while a high-power motor requires a large current. If a motor is driven by a battery or a controller that supplies too much current, it can cause the motor to fry or get damaged.

To properly wire a servo motor, its three wires must be identified. These wires usually consist of a power (red), ground (black or brown), and signal (yellow or white) wire. The power wire should be connected to the positive terminal of the power source. The ground wire is connected to the negative terminal or ground. Finally, the signal wire is connected to the control unit or microcontroller. This step ensures that the motor receives the right power and control signals needed for operation.

Mounting the motor onto a stable surface is important, as this provides a steady base for the components. To do this, the servo motor must be securely fastened using screws or clamps. In the cases where arms or gears are used to extend the motor's function, these components should be attached to the motor. This is done by connecting the motor's output shaft to the gear or arm and by using a servo saver. The gears or arms should then be connected to any tools or other instruments to extend the motor's use.

Testing the system is very crucial, as it ensures that everything is working properly. To do this, a control system is used to send commands to the servo motor. After this, the responses of the motor are observed to see if the components move correctly. During the process, all connections should be inspected to see if they are appropriately and healthily working. In a case where any issues arise, the wiring and connections should be corrected before proceeding.

Regular cleaning is very important to ensure the proper working condition of the device. It helps in the removal of dust and debris, which may affect the components. The device should be inspected often for damages like frayed wires or broken parts. This helps in catching issues early, and the damaged parts can be repaired or replaced in time to give the device a longer life. While using the motor, overheating should be avoided, as high temperatures can damage the internal components. The motor should be allowed to cool down in case it gets too hot. Also, proper lubrication aids in the smooth functioning of the motor. Lubricants help reduce friction, which may affect the motor in the future. However, care should be taken not to over-lubricate, as this may cause more harm than good.

In case the servo motor breaks down, the first step is to identify the problem. This involves checking for common servo motor problems like lack of response, jittery movements, or strange noise. Identifying problems is important, as this helps find the right solutions. Consulting the manufacturer's guide for troubleshooting tips can also help in the process. If the motor has any damaged external components, they should be replaced first before any internal checks.

If the motor is internally damaged, it is advised to get help from a professional. Although some parts of a servo motor, like gears, can be replaced easily, other components require a professional. Servos that have strong internal damages will require replacement, as that will be the only solution in the case. Using authentic parts in the replacement process is vital, as it ensures the motor works the same way afterward.

Durability

3-volt motors are made strong. They last long because they can handle getting used a lot without breaking down. People don't need to change them as often, which saves time and money when using them in things like robots and tools.

Materials

The parts of 3-volt motors are made from good stuff that doesn't wear down fast. Even when used a lot, like in machines and cars, the materials hold up well and continue working properly. This means less fixing and longer time working for the things they power.

Weather conditions

These motors work well in different weather, from hot to cold and even damp. They keep going even when the environment changes, so things like outdoor tools keep working no matter the day-to-day weather changes.

Internal Components

The small parts inside 3-volt motors are built with care using strong internal components. Even though they are small, they are designed to ensure effective functionality over time, whether in home gadgets or big machinery. The attention to detail in crafting each internal component enables smooth operations, minimizing wear and tear, and further enhancing the motor's longevity and reliability.

Power supply

Since it runs on a low voltage, care should be taken not to pair it with a high voltage, as this may cause a fire. Where batteries are used, users should ensure they are properly fitted to prevent short circuits, which may also lead to fire.

Overheating

The operational heat level of these motors is considered low. However, it should not be allowed to run for a long time without a break. In case it runs for long, break periods should be given to cool it down.

Intrusions

The 3v dc motor is made for small machines. It is of low voltage, meaning it is safe for most tasks. To make it safer, avoid using it with dangerous tools like saws or big machines that may have high power to prevent fire or other damage. Even if it looks small and harmless, always handle it carefully and keep it away from kids. Only trained adults should work with it.

Using Casing

Many servo motors come with a casing. Casing is meant to keep dust and other small things from getting inside the motor. This helps the motor run well for a long time. When the motor is being installed, ensure that the cover is put on it, so nothing gets inside and stops it from working.

Testing over loads

It should be tested to ensure it is safe to work with any load. This means making sure it can carry the weight of what it's moving. If the motor is trying to do too much at once, it gets hot, and this is not good. It is better to check and make sure it's not overloaded.

A1. It all depends on the application. For some common parts, it can move just a few tiny millimeters each time, and for robots, it can move less than 0.01 of a millimeter! It can also handle pretty big forces, like pushing or pulling something heavy.

A2. Lots of different places use these motors. Factories use them to help make things faster and nicer. Farmers use them in their machines to make farming easier. Doctors use them in their tools to do surgeries. Even in entertainment, like theme parks or robots! They really help make everything work best.

A3. They can work for a long time, but they are not really made to keep going on and on all the time. It's best if they take little breaks now and then to cool off. This helps them keep working strong for many years.

A4. A little computer called a controller tells the servo motor what to do. It sends signals to help the motor move to just the right spot and hold it there. The controller works with a sensor that checks to see if the motor is in the correct position. If it moves away, the controller quickly adjusts to put it back in place.

A5. Things like durable gears, good-quality materials, and a powerful motor give a servo its strong abilities. Certain features enable the motor to handle heavy tasks efficiently.