All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(51 products available)

A ultrasonic distance sensor 40khz is an advanced measuring tool that uses sound waves to remotely assess proximity. It emits ultrasonic waves and receives the echoes that bounce off objects to estimate their distance.

Sensors With Integrated Output

Many ultrasonic proximity sensors include the output stages necessary for their operation. Common outputs are relay contacts or analog signals, like 4-20 mA current loops or voltage variations. These sensors directly interface with control devices, eliminating the need for extra signal conditioning.

Compact and Miniature Sensors

Small electronic parts can do a lot in limited spaces. Compact sensors are ideal for tight areas in robots and mobile devices. Advanced sensor tech makes these tiny sensors precise. Big sensors are not the only option for tasks; small ones work too.

High-Temperature Sensors

Ultrasonic proximity sensors can work in places with lots of heat, like furnaces or engines. Special materials allow them to endure high temps where standard sensors would fail. They measure object positions in extreme settings safely and reliably.

Sensors With Different Frequencies

Ultrasonic sensors operate at various frequencies, though 40 kHz is common. Higher frequencies allow for precise short-range detection, while lower frequencies cover longer distances. Each frequency suits a certain type of work and the environment. Choosing the right one depends on what is needed.

Collimated Beam Sensors

With a directed sound wave, collimated sensors detect at longer ranges. The focused waves make it easy to spot targets far away. Other sensors might struggle at a distance, but these maintain accuracy with their sharp sound beam. They are great for checking open areas from far off.

Robot Navigation And Obstacle Avoidance

Robots use ultrasonic proximity sensors to find their way. The sensors send out sound waves to detect nearby things, helping the robots move without crashing into anything. This is useful in factories where robots need to work safely next to people and other machines. The sensors let the robots check their surroundings and stay on course.

Automatic Door Systems

Many sliding doors use sensors to open and close. Ultrasonic sensors send out sound waves to spot people nearby. If someone gets close, the door sensor sends a signal to open the door so they can walk through. When the person steps back, another sensor detects it and tells the door to close. This helps doors work smoothly without switches.

Agriculture And Field Monitoring

Sensors are used on farms to check crops from the air. Drones or machines fly over fields, and the sensors map plant growth and health. The sound wave sensors capture picture data about the plants. This helps farmers see which crops need water or help. The sensors do this better than humans on large farms.

Waste Management Systems

Sensors in trash bins make waste collection smarter. The sensors use sound waves to check how full each bin is. They send the data over wireless networks so workers know which bins need emptying first. This saves time and makes the pickup routes quicker. Sensors manage waste without having to check each bin by hand.

Level Detection In Liquids And Solids

Proximity sensors use sound waves to measure levels of liquids and solids. They send out waves that bounce back from the top of the material. This shows how deep the liquid or solid goes in a tank. It enables sensors to track levels and send alerts when empty or too full. Ultrasonic sensors work well in tough environments for reliable readings.

Range and Sensitivity

Ultrasonic distance sensors can check distances from 20 cm to 6 m. Their sensing area stays even if the temperature or humidity changes. This keeps the readings accurate no matter the conditions.

Power Supply

The sensors get energy from 5 to 15 volts of direct current. Common sources include batteries or power adapters. They use very little power to run for long periods without wasting energy.

Output Types

Many ultrasonic sensors have different output formats. Some send analog signals, like varying voltage levels. Others use digital signals, sending on/off commands. The right output depends on what the sensor is used for. This makes it simple to link the sensor to different devices and systems.

Sensing Angle

The area that the ultrasonic waves cover is about 30 degrees. Within this space, the sensor can locate objects. This angled pattern lets the sensor see more side to side. It can check a wider area around it compared to others.

Temperature and Humidity

These sensors can work across a wide range of temperatures, from -10 to 60 degrees Celsius. They also handle changes in humidity without issue. This allows them to perform well outside or in spaces with fluctuating conditions.

Installation and Mounting

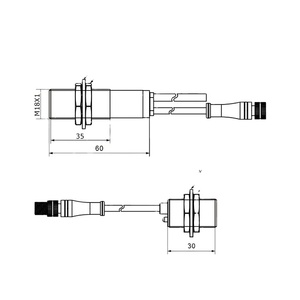

Mounting the sensors on machinery or in areas is easy. They come with brackets or other ways to attach them securely. Setting up the sensors doesn't take much time. Getting them in place is fast for users.

Durability

Ultrasonic proximity sensors withstand dirt, dust, and shocks. They are built tough for factories and other rough places. This protects them from damage in harsh settings.

Mounting ultrasonic sensors is a simple process. First, decide where the sensor should go based on what it needs to measure. Then, use the provided mounting bracket to attach it to a wall, machine, or ceiling. Be sure to set the sensor at the right angle and height for the task. Next, connect the sensor to power using a cable. Check the sensor's manual for how to wire it properly.

After wiring, link the sensor's output to a control system or alert device. This will give readings or notifications when something is detected. Finally, test the sensor to make sure it works. Walk in front of it and see if the output responds like expected. Adjust the angle or settings if needed. This ensures the sensor performs well in any situation.

Maintaining ultrasonic sensors is straightforward. Start by wiping the sensor head with a soft cloth. This removes dust that can block the signals. Next, check the wires for any damage.

If they are broken, replace them so the sensor operates correctly. It is also important to keep the sensor software refreshed. Look online for any software updates and install them to improve the sensor's performance.

Lastly, have a professional inspect the sensor after a year. They will check that everything works as it should. With these easy tasks, the sensor lasts a long time and gives accurate readings.

The Build Material

Ultrasonic sensors are built with solid materials for durability. Their steel housings protect against damage in tough environments. This steel shields the sensor from dirt, dust, and heat. Inside, stronger electronic parts handle vibrations and shocks well.

Sealing

The sensors are carefully sealed to block liquids and small particles. This sealing keeps them working in wet or dirty areas. It also helps the sensors do their job in factory spaces where failures often happen.

Testing Standards

These sensors go through testing to meet strict durability rules. This ensures they can perform reliably for many years, even under heavy use. Users can trust them to work in all conditions.

Shock Absorption

These sensors have parts that soak up shocks and vibrations. This protects the sensor from damage when it experiences sudden jolts or shakes. It allows the sensor to stay accurate even in rough working environments.

Operating Conditions

Ultrasonic proximity sensors can operate in extreme temperatures from -20 to 70 °C. They also work in dusty or humid air. This wide range of conditions ensures they remain functional and accurate no matter what.

A1. An ultrasonic proximity sensor uses sound waves to check how far or close something is. It sends out sound waves and listens for them to bounce back. This lets it measure the distance to an object in its way.

A2. Ultrasonic sensors are used for many things, like helping robots locate objects, measuring liquid levels, and checking distances in manufacturing. They work well indoors and outdoors and can detect materials that are hard to see with other methods.

A3. The sensor emits a pulse of sound waves at a high frequency, around 40 kHz. It then listens for the waves to bounce back after hitting an object. By calculating the time the waves take to return, the sensor figures out the distance to the object.

A4. They provide accurate readings, even with varying temperatures or surface types. They also work in tough conditions like dust, fog, or dirt that might block other types of sensors.

A5. Yes, ultrasonic sensors can be used indoors and outdoors. They perform well indoors without interference. Outdoors, factors like wind or moving animals might affect the readings. However, they still work effectively in many outdoor environments.

A6. Most ultrasonic sensors can measure distances from around 20 centimeters up to about 6 meters. Some advanced models check distances even further, up to 15 meters or more.

A7. The sound waves are at a frequency of about 40 kHz. This is much higher than a human can hear - around 20 kHz. It allows the sensors to work accurately while remaining undetected by people.