All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(38 products available)

The 94vo 2-layer PCB board comes in diverse types. They include:

Standard 2-Layer PCBs

Usually, a standard 2-layer PCB is the most basic kind of multilayer circuit board. Commonly, this type carries out simple, cost-effective designs that require basic connectivity. Usually, these boards are used in applications that do not need dense component placement or complex circuitry. Sometimes, the boards are utilized in consumer electronics, and basic control systems.

Multilayer PCB

This kind of board is made to support more complex circuitry by providing extra layers for more component connections. Commonly, they are ideal for advanced electronics that need compact designs. Usually, this allows for a denser arrangement of components.

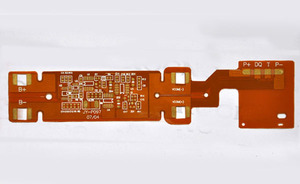

Flexible PCBs

Often, flexible PCBs are fabricated with 94vo material and are designed to be bendable. This allows for versatility in applications that require the board to be fitted into spaces with uncommon shapes. Besides, they are used in devices such as smartphones and medical equipment that need lightweight components.

RF-PCB

Normally, RF-PCBs are developed for high-frequency applications. Ideally, they are constructed with materials that offer low signal attenuation. Usually, this ensures a high level of performance for radio frequency devices. Additionally, they are commonly utilized in telecommunications, satellite systems, and other wireless applications.

High-Frequency PCBs

These PCBs are designed for specialized applications that require transmission above 1 GHz. Therefore, they are constructed using 94vo material and incorporate substances that can efficiently transmit signals at such frequencies.

4-layer PCB

Typically, these boards offer additional routing capabilities. This makes them suitable for more complex electronic devices requiring extra connections. Besides, a 4-layer PCB is beneficial in applications that need enhanced signal integrity and reduced electromagnetic interference.

The double-sided 94vo pcb serves varied applications. They include:

Telecommunications

Often, these circuit boards are utilized in phones, routers, and communication satellites. Normally, they support signal transmission and reception. In addition, their reliability ensures efficient data transmission, making them critical for indoor and outdoor telecommunications systems and infrastructure.

Medical Devices

Normally, PCBs are essential in medical equipment such as diagnostic tools, monitoring systems, and treatment devices. Also, their role in ensuring accurate readings and patient data management contributes to the reliability of life-saving medical technology. Typically, this makes them vital for health and safety compliance.

Industrial Control Systems

Commonly, these PCBs manage machinery and automation systems. Therefore, they enhance operational efficiency in factories and industrial settings. Usually, due to their ability to endure harsh conditions and support complex functions, they are critical in maintaining control and monitoring in industrial environments.

Consumer Electronics

Often, these PCBs are found in varied consumer devices like smartphones, tablets, and home appliances. Moreover, their contribution to device functionality and durability affects performance. Also, they impact user experience. Additionally, the role of these boards in supporting connectivity and component integration makes them essential for modern electronic devices.

Aerospace and Defense

Usually, in aerospace and defense applications, these PCBs are used in avionics systems, radar technology, and navigation devices. Normally, the high-quality standards and reliability of these boards ensure safety and performance in mission-critical systems. Thus, their use in this industry demands stringent requirements for durability and functionality.

Automotive Systems

Commonly, these PCBs are used in advanced driver assistance systems (ADAS), infotainment systems, and engine control units (ECUs). Also, their ability to function reliably. This enables them to withstand automotive environments with temperature fluctuations and vibrations. Further, they support the growing trend of connected vehicles and electronic systems integration.

Lighting Technology

Often, they play a key role in LED lighting solutions. More often than not, they manage energy efficiency. In addition, with their compact design, these boards facilitate innovative lighting applications. This includes smart lighting systems that allow for improved functionality and reduced energy consumption.

The 94vo 2-layer PCBs have diverse features and specifications. These are:

Material Composition

Usually, the construction of these PCBs incorporates a base material. Standardly, it is FR-4, a flame-retardant epoxy resin. Additionally, this material is renowned for its excellent electrical insulation, mechanical strength, and thermal stability. Ideally, they form the foundation of the board structure.

Layer Configuration

Size and Thickness

Their sizes vary based on the specific requirements of the application. Often, these PCBs commonly range from 1.6 mm to 0.8 mm in thickness. In addition, a standard 1.6 mm thickness offers a balance between rigidity and flexibility. Therefore, it enables easy handling during manufacturing and assembly.

Surface Finish

Commonly, surface finish options for 94vo 2-layer PCBs include HASL (Hot Air Solder Leveled), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives). Usually, these finishes protect the exposed copper traces. In addition, they enhance solderability. They also ensure reliable component attachment during the soldering process.

Thermal Properties

These PCBs have exceptional thermal properties. Therefore, they can efficiently dissipate heat generated by electronic components. This property is crucial for maintaining the functionality and longevity of devices operating in high-temperature environments. Moreover, it prevents overheating and circuit failure.

The Pcb 094 can be durable in a variety of ways. These include:

Material Selection

Apart from using high grade FR-4, reputable manufacturers of 94vo 2-layer PCB boards usually opt for quality materials. This includes copper with high thermal conductivity. Moreover, the quality materials enhance heat dissipation throughout the board. Therefore reduces the risk of damage caused by temperature fluctuations.

Layer Configuration

Usually, the 94vo 2-layer design provides a balance between flexibility and robustness. In addition, the configuration supports complex electronic circuits and ensures durability, especially in compact devices. Therefore, it is crucial for maintaining functionality in environments that undergo constant movement or stress.

Manufacturing Precision

Often, manufacturers with state-of-the-art technologies ensure precise fabrication of the layers and circuits. This improves durability through better component adhesion and reduced risk of delamination. Therefore, quality manufacturing practices enhance circuit integrity and promote long-lasting performance.

Surface Finishes

Standardly, several surface finishes such as HASL and ENIG are utilized to protect the copper traces against corrosion and wear. Usually, these finishes improve the solderability of components. Therefore, they establish stronger connections that can withstand thermal cycling and mechanical stress in the long term.

Testing and Quality Control

Ideally, implementing rigorous testing standards is important. Often, techniques like electrical testing and thermal profiling are conducted, mitigating potential failures. Also, boards that undergo comprehensive quality control are durable as they meet the established reliability standards for varied applications.

Application in Harsh Environments

These PCBs are made with longevity in mind. Specifically, in demanding environments, such as industrial settings or outdoor equipment, their robust construction ensures they can handle extreme temperatures, moisture, and vibrations. This makes them suitable for military, aerospace, and automotive applications requiring unfaltering performance under adverse conditions.

EMI and RFI Shielding

These two are critical for the durability of electronic devices. Normally, proper design of 94vo PCBs minimizes electromagnetic interference (EMI) and radio frequency interference (RFI). This protects the circuit from signal degradation. Therefore, this ensures reliable performance in sensitive electronic devices. It includes medical equipment and communication systems that experience environmental interference.

Often, 94vo 2-layer PCBs are preferred in consumer electronics due to their durability. Conventionally, they are used in smartphones, tablets, and home appliances. Further, the boards support efficient circuit designs for high performance. In addition, they manage the complexity of modern electronic devices while remaining cost-effective.

Typically, surface finish protects the copper traces from oxidation. Further, it improves the solderability of components. Additionally, common finishes like HASL and ENIG ensure long-term durability, thermal cycling, and mechanical stress resistance. This makes them ideal for various applications.

These PCBs are ideal for industrial applications. They can bear harsh conditions. They offer excellent thermal management in high-temperature environments. Moreover, their reliability contributes to the stability and efficiency of industrial machinery and control systems.

The “94” in 94vo denotes its flammability rate. Ideally, it refers to the UL 94 standard for safety. Therefore, this indicates that these PCBs have a higher resistance to catching fire. This is a result of their robust chemical composition. Hence, these boards are increasingly applied in areas that require enhanced safety features. This includes automotive and medical devices.

Quality control is vital for preventing electronic failures. Usually, it ensures the boards are tested for electrical integrity and thermal performance. Therefore, stringent quality control practices are paramount in guaranteeing reliability in mission-critical applications. This includes aerospace and medical devices.