All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1145 products available)

There are several types of automatic plastic snap button machines.

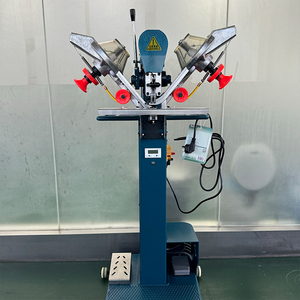

Automatic Snap Button Machine

This machine puts the top and bottom together using a heat process. It has a part to heat the pieces, a part to put them together, and a worker-free design. It puts together many buttons very quickly. This system works well on large jacket and bag orders that require many snaps. Because it operates fast, it lowers costs for big tasks.

Automatic Press Snap Button

The Automatic Snap Press uses a press to attach buttons or snaps. It can attach different size snaps to many types of fabrics. The press is strong yet gentle, so all fabrics stay smooth. Using this snap press cuts the time needed to sew on buttons by half. This allows more items to be finished each hour.

High-Speed Snap Button Machine

This machine is made to work faster than other snap buttons. Its high speed makes it good for working on a layout with lots of buttons at once. Even if a layout has densely packed buttons, this machine can get the job done in no time. Its efficiency cuts down on how long it takes to finish each layout. As a result, companies can complete more installations swiftly.

Automatic Die Snap Button Machine

The Automatic Die Snap Button Machine uses shapes to cut materials for making buttons. The die presses shapes into the fabric to create new textured design buttons. This system produces buttons with intricate designs quickly and precisely. Orders with large needs for customized design buttons will get filled fast with this machine. Its automatic die-cuts replaces hand-cutting for speedy production.

Multi-Functional Snap Press Machine

This snap press can get many different tasks done in one machine. It can attach buttons, make buttonholes, and sew firmly all on its own. Workers do not need to help out much, so it works quickly. This press saves time and space by combining different tools. It allows companies to get through more jobs in less time.

Textile Industry

These machines quickly put snap buttons on clothes, coats, and uniforms. When making large clothing batches, human workers would take too long. The machine saves snaps by pressing them all on at once.

Leather Goods Manufacturing

Purses, belts, and other leather products use these machines to install snaps securely. For complex leather designs, hand-sewing snaps is hard. The machine presses each snap on perfectly straight and tight.

Baby Products Construction

These machines add safety snaps to baby items like diapers and baby carriers. The snaps help keep items securely fastened and safe. Automated installation ensures that all baby products pass necessary safety checks. Textile Repair Kits

In coat repair kits, these machines use snaps to patch up holes or replace broken parts. Using snaps instead of regular buttons makes the repairs last longer. The machines work fast to help hotels or organizations complete repairs in a timely manner.

Sports Gear Production

In tents, backpacks, and other outdoor gear, these machines securely install plastic snaps. Snaps let pockets and zippers open and close easily. Automated installation handles large quantities smoothly.

Commercial Upholstery Work

These machines add snaps to large furniture items like sofas and chairs. For extensive upholstery work, hand-sewing snaps takes too long. The machine presses each snap on precisely to improve quality.

Materials

Automatic snap button machines can work with many kinds of materials like plastic, metal, and fabric. Each material makes the buttons last longer in different ways.

Production capacity

Many machines can attach around 1200 buttons every hour. This helps larger businesses produce more clothing or gear.

Power consumption

Snap machines normally use about 800 watts when they are working. That is similar to a regular computer. This means energy bills will not be too high.

Speed

The fastest machines can put on over 50 buttons in just one minute at top speed. However, many customers choose slower settings to work better with thinner fabrics.

Dimensions & Weight

Most machines weigh between 100 and 200 pounds. This gives them a sturdy build, but they are still light enough to move if needed. They also take up around 4 square feet of space.

Automatic operation

This means the machine can place and attach all the buttons without anyone needing to help it. It works by itself on the different tasks to get things done faster.

Multiple snap sizes

An automatic plastic snap button machine can handle small snaps that are around 8 millimeters wide, up to larger ones that are 13 millimeters across. This versatility allows the machine to be used for different jobs, as clothing manufacturers often need snaps in various sizes for their garments.

Durable construction

The main parts of the machine were designed to last a long time, even with heavy usage. Tough materials ensure it constantly builds quality clothing day after day.

Safety features

Special guards prevent accidents while the machine is working. These keep the surrounding area safe for everyone.

Customizable settings

The speed and snap size options can be adjusted based on the particular needs of each job. This tailoring helps make the process as efficient as possible.

Speed and efficiency

Working quickly allows larger projects to get finished in less time. This increases efficiency and productivity compared to doing things by hand.

To select the right automatic plastic snap button machine, consider these important factors. Keep all of these aspects in mind while looking through available options.

Durability

Choose a sturdy machine from strong metals like steel. This ensures it lasts through heavy daily use. Research the brand's reputation for making tough, long-lasting products.

Business needs

Consider the types of buttons snapped together for working on various fabrics. Make sure the machine can handle snaps in different sizes and materials that are needed for the clothing projects.

Budget

Figure out how much is planned to spend in total. Keep in mind that investing in a higher-quality, more efficient machine may pay off in productivity savings down the road. However, also don't forget about any additional costs, such as for maintenance or operating, that will need to be factored in.

Speed

Larger commercial machines operate at a faster pace, which is ideal when tackling big projects on time. The processing speed is an essential consideration, especially when dealing with large orders or projects.

Warranty

Look for a lengthy guarantee that shows the manufacturer backs their work. This provides confidence in the purchase. A strong warranty demonstrates that the company believes in the quality and durability of their product.

Ease of use

Choosing a model with clear directions and simple controls makes operating it much less of a chore. Additionally, training new users will be faster.

Maintenance

Check how often routine servicing will be required and if it's a straightforward process. Low-maintenance machines mean less downtime in the future. This, in turn, helps keep the projects on schedule.

Customer support

Look for companies that provide good online or by phone support if any issues arise down the road. This helps get problems fixed promptly when they come up during use. Reliable support ensures that assistance will always be available if needed.

A: It puts plastic snap buttons on clothes and gear really fast and by itself.

A: It puts snaps on jackets, bags, uniforms, baby items, and more made of fabric or leather.

A: By working automatically and really fast, it saves hours of sewing by hand.

A: Yes, it's great for large orders of thousands of snaps. Bigger machines make bigger quantities even quicker.

A: Yes, controls are simple and there are instructions, so it's not hard to run the machine.

A: If anything goes wrong that shouldn't, the warranty covers it. It shows the company stands behind the product.