All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1416 products available)

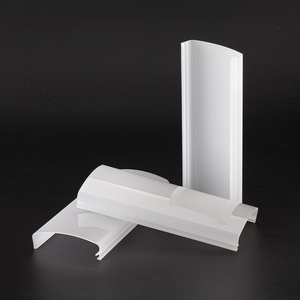

Custom made LED strip diffusers are tailored solutions designed to meet specific lighting needs and aesthetic requirements. Custom diffusers help to modify and enhance the light emitted by LED strip lights in various applications. Here are the types of custom made LED strip diffusers:

Frosted Diffusers

Frosted diffusers are plastic sheets that have been treated with sandblasting or a special coating on one or both sides to create a translucent, matte finish. The LED light is spread out evenly via these diffusers, reducing hot spots and producing a soft glow. They are suitable for residential settings, office lighting, backlit signs, and displays.

Opal Diffusers

Opal diffusers have a milky white appearance and are made from materials like polycarbonate or acrylic. They offer high light diffusion while maintaining a good level of light transmission. The LED light is scattered uniformly across the surface via these diffusers, producing a soft, ambient illumination with minimal glare and hotspots. They are suitable for applications requiring balanced, diffused lighting, such as commercial and residential spaces, offices, and retail environments.

Textured Diffusers

Textured diffusers have a specific pattern or texture molded into the surface of the acrylic or polycarbonate material. The pattern can be frosted, clear, or a combination of both. The light from the LED strips is refracted and scattered by the varying surfaces within the diffuser. This results in a visually interesting and diffused light output. These diffusers can produce unique lighting effects due to their design. They are suitable for custom lighting designs, architectural applications, and areas where a textured effect is desired.

Prismatic Diffusers

Prismatic diffusers have a textured surface with small, angled prisms that bend and focus light. They enhance brightness and direct light where needed. Prismatic diffusers can increase illumination levels and improve the efficiency of lighting fixtures by redirecting light output from LEDs. They are suitable for task lighting areas, commercial spaces, and applications where increased brightness is required without increased glare.

Milky Diffusers

They are made from materials such as acrylic or polycarbonate mixed with diffusing agents. The diffusers scatter light uniformly to produce a soft, ambient glow. They reduce glare and minimize visible LED hotspots. Milky diffusers help improve the overall aesthetic quality of the lighting. They are suitable for applications requiring high levels of illumination, such as offices, workshops, and retail spaces.

Colored Diffusers

Colored diffusers are made from materials that have been tinted or coated with color additives during manufacturing. They control the color of transmitted light to produce ambient lighting effects. They can create visually striking effects by integrating various colored diffusers into LED setups. For instance, blue or red diffusers can be used to produce specific moods or atmospheres. These diffusers are suitable for accent lighting, mood lighting, and decorative applications.

When looking for custom LED diffusers for lights, it is important to consider the following features and functions to ensure the right product is selected.

Light Diffusion

This is the main function of LED diffusers. They distribute light evenly across the surface to reduce hot spots and glare. Custom diffusers are designed to meet specific lighting requirements such as achieving desired brightness or reducing glare.

Material

Diffusers are made from different materials such as acrylic or polycarbonate. They are durable and provide long-term service. The materials have a high light transmission capacity which ensures maximum light output. They are also resistant to yellowing and offer clarity.

Customized Shapes and Sizes

Custom LED diffusers can be made in different sizes and shapes to fit various applications. This ensures they fit perfectly in designated spaces and provide the required light output. This also allows the diffusers to be used in different designs and configurations to enhance their aesthetic appeal.

Easy Installation

Custom LED diffusers are made for simple and easy installation. They come with mounting options that allow them to be installed on existing setups without requiring additional hardware or tools. This saves time and reduces costs during installation.

UV Resistance

Some custom diffusers have UV resistance features. This ensures they are protected from harmful UV rays that can cause damage over time. This increases the lifespan of the diffusers and ensures they offer long-term service.

Heat Resistance

LEDs produce heat when they are working. Heat-resistant LED diffusers can sustain high temperatures without losing their structural integrity. Heat resistance ensures the diffusers are not deformed or melted, which would affect their performance.

Compatibility

Custom made diffusers can be compatible with different types of LED strips. This makes them versatile and useful for various applications. They are compatible with rigid LED light bars and flexible LED strips.

Design Flexibility

Designers can customize LED diffusers to meet specific requirements for lighting intensity, color temperature, and distribution. This flexibility allows for optimized lighting solutions for different environments. This feature allows the lighting to be tailored to fit individual needs and preferences.

Custom-made LED diffusers are versatile and can be applied in various industries and sectors. Here are some common application scenarios:

Architectural Lighting

Diffused LED lights are used in lighting building projects, historical sites, and other structures. They offer an even wash of light on walls and ceilings without obstructing the view of the architectural features. Custom diffusers are designed to meet specific requirements of different applications. For instance, some provide colored lighting effects while others offer white light diffusion.

Interior Design and Home Lighting

Custom LED diffusers are used as part of light fixtures. They are installed in ceilings, under counters, in cabinets, and in other places. They offer soft, uniform lighting that improves the overall ambiance and minimizes glare. Moreover, they can be designed to match specific décor themes and lighting requirements.

Commercial Lighting

These diffusers are used in offices, retail stores, restaurants, hotels, and other commercial establishments. They provide attractive lighting that enhances interior design and improves visibility of products. Also, they create pleasant environments for customers and employees. Normally, they are integrated into troffers, pendant lights, and other commercial light fixtures.

Automotive Lighting

In the automotive industry, custom LED diffusers are used in headlights, taillights, brake lights, indicator lights, dashboard illumination, and interior lighting. They ensure uniform light distribution, improve visibility, and offer a cohesive look to the vehicle’s lighting system.

Electronics and Displays

Custom LED diffusers are commonly used in LCD and LED monitors, laptops, tablets, smartphones, and other electronic devices. They enhance backlight uniformity and diffusion. Additionally, they reduce glare and improve visibility of the display under varying lighting conditions.

Signage and Wayfinding

These diffusers are used in illuminated signs, billboards, direction boards, and other forms of light signage. They provide uniform light distribution that improves visibility of the signage from different angles and distances. This makes it easier for pedestrians and drivers to see and read the signs, especially in low-light conditions.

Agricultural Lighting

Custom LED diffusers are used in greenhouse lighting and other controlled agricultural environments. They provide uniform light spectra that promote plant growth and development. Also, they improve light penetration and reduce hotspots.

When selecting a custom LED strip diffuser, consider the following factors:

Diffusion and Light Output

Different diffusers have various light diffusion abilities. Clear diffusers allow more light, while frosted ones spread it softer. Consider what brightness vs. softness is needed. Test samples to see how each diffuser affects the LED strip's light output.

Materials

Common diffuser materials include acrylic and polycarbonate. Acrylic is lighter but may yellow over years. Polycarbonate lasts longer before yellowing. Consider material lifespan based on how long the lights will be used each time. Choose a material that meets the expected durability needs.

Compatibility

Make sure the diffuser works with the LED strip dimensions. Check width and depth will fit. Also confirm the heat - LED strips produce heat - can be managed by the diffuser. Some designs handle heat better than others. For high-heat strips, select a diffuser made for them so safety is assured.

Installation

Look at how the diffuser will be attached. Options are: clips, adhesive or mounting tracks. Clips can be removed easily. Adhesive is permanent. Tracks are good for long runs. Weigh the pros and cons of each attachment method before deciding.

Customization Options

Various choices are available to customize the diffuser. Select the right diffusion level, surface texture and material thickness. Work together with the supplier to fine-tune these details. This ensures the final product meets all lighting needs perfectly.

Additional Features

Extra features can enhance the diffuser. UV stabilizers stop yellowing from sunlight. Anti-glare coatings reduce harsh glares. Consider if these additions would benefit the specific lighting design. Ask the supplier what options are available to include.

Quality and Reviews

Before purchasing, research the supplier's reputation. Read reviews to see what past customers experienced. Check the quality of their diffusers - are they long-lasting and performed as promised? Analyzing feedback helps choose a provider who will deliver reliable products.

Q1: Are custom-made LED strip diffusers cost-effective?

A1: Generally, the answer is yes. Although buying custom diffusers might seem more expensive than buying standard ones, it is often not the case. Custom diffusers eliminate the need for additional modifications or installations required for standard diffusers to fit specific LED setups. Moreover, custom diffusers provide optimal light distribution, reducing the need for additional accessories, which leads to overall cost savings.

Q2: What is the lead time for custom LED diffusers?

A2: The lead time for custom LED diffusers varies from one manufacturer to another. It also depends on the complexity of the design and the size of the order. Generally, the average lead time ranges from 10 to 20 days. In some cases, it can take longer than 20 days if the order is very large or the designs are very complex. Customers are advised to contact the manufacturer to get the exact lead time.

Q3: What materials are used to make custom LED diffusers?

A3: The most common materials used to make custom LED diffusers are acrylic and polycarbonate. They are both durable and offer excellent light diffusion. In some cases, depending on the customer's preference, LED diffusers can also be made using glass.

Q4: Can custom LED diffusers be reused?

A4: Yes, but this is only possible if the diffuser has not been damaged. It is also only possible in situations where the dimensions and design of the new LED strip light are compatible with the existing diffuser. In general, reusing a diffuser is not cost-effective. As such, the option of reusing diffusers is not popular among manufacturers and customers.