All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(34013 products available)

Plastic Inoculating Loops

Because they are light and inexpensive, plastic inoculating loops are highly accepted. These loops are constructed of high-quality, sterilized plastic before being packaged to ensure they stay sterile until needed. Because they are light and inexpensive, plastic inoculating loops are highly accepted. When executing microbiological tests, especially when working with multiple samples or cultures, labs prefer using plastic loops since they are resistant to breaking.

Steel Inoculating Loops

Steel inoculating loops are preferred due to their strength and durability. Typically, loops are made with wire that has been shaped and then coated with a steel layer for better protection against corrosion. Loops made of steel are advantageous since they can tolerate high temperatures and can be cleaned by sterilization. These loops are frequently found in research and clinical labs where frequent, careful, and extensive use is required.

Inoculating Needles

Inoculating needles perform an identical role to inoculating loops but are mainly for use in transferring bacterial cultures. These needles, constructed from sterilized wire, are shaped into a pointed tip for purposes of making straight or punctiform inoculations in culture media. For instance, inoculating needles would be best suited for deep inoculations in broth, agar stabbing, or other solid forms of medium. Like inoculating loops, needles must be sterilized before every use.

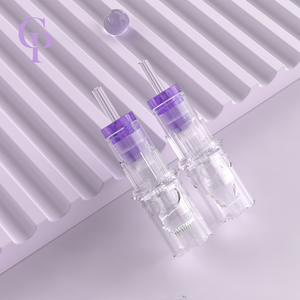

Inoculating Loops with Retractable Ends

Retractable inoculating loops are a developing form of this tool wherein the looping end can be hygienically retracted following use. The construct of retractable loops is such that it provides sterilization of the loop by having the end recede into the handle where it gets covered solitarily inside the handle's casing. This self-sheltering feature makes it an easier and more efficient way to ensure that the equipment used does not cross-contaminate the cultures.

Material Composition

When selecting disposable inoculating loops and needles, the refiner should consider material composition.

This is because sterilized metal wire offers more durability and is quite preferable in laboratories where high temperatures and repeated usage are almost mandatory. On the other hand, plastic inoculating loops have taken the market by storm, thanks to their relatively lower prices, lightweight structure, and impressive corrosion resistance. In industries where healthcare workers predominantly use these loops, undue breakage can lead to severe infections. Therefore, choosing material composition that is compatible with the environment in which it will be utilized is highly advisable.

Sterilization and Packaging

Another important consideration when it comes to inoculating loops and needles is packaging and sterilization.

This ensures that the product to be used remains free from any microorganisms. Observing this factor, however, should be carefully done at the time of purchasing the product. Suppliers and manufacturers should stock and sell products that are sealed in sterile packaging. This is to make sure that the sterilization remains untouched during the logistics process. In this case, the expiration date is another critical factor in packaging that needs to be accounted for. This is due to sterilization apparatuses like infecting needles and loops having expiration dates, which must be adhered to so as not to lose effectiveness with time.

Loop Size and Design

The size and shape of inoculating loops may vary depending on the type of culture and the specific microbiological method needed.

While larger loops are more favorable for transferring larger quantities of bacterial liquid, smaller loops are appropriately used for the quadrant streaking method, where only small drops are required. Also, straight production of loops or those that have a slight angle of turn are well intended for smooth inoculation; however, that might become a further complicated inoculation process.

Use Case and Industry Requirements

The selection of inoculating loops and needles is generally affected by the kind of industry or field where they will be used.

For example, in healthcare and clinical laboratories, where bacterial culture identification is a valuable diagnosis activity, there is a dire need for high-quality, disposable steel loops and needles. These inoculating apparatuses are utilized on a much smaller scale in food and beverage industry microbiology quality control labs. In the farming, pharmaceuticals, or biotechnology industries, local ware and tear cultures, media types, and pathogens can give insight into the most effective and commonly used inoculating tools in the lab.

Inoculating loops, needles, and instruments are vital items in microbiological labs for culture handling. Here are the major specifications related to these products:

Loop Size

This diameter varies, with typical sizes between 3 mm and 5 mm. For large streaks or transfers, wider loops are used, while narrower loops are applied for tiny, precise transfers. Inoculating loops possess sizes that align with specific microbiological techniques and requirements.

Needle Gauges

Inoculating needles are available in different gauge sizes; consequently, higher gauge numbers mean narrower needles.

The gauge sizes usually range between 20 and 30. Smaller gauge numbers are applicable in transferring more viscous substances, whereas smaller numbers are for transferring more fluid cultures. This adjustment is needed to enhance flexibility and functionality in the varied culture media.

Loop and Needle Length

Typical lengths of inoculating loops vary between 10 cm and 15 cm; on the other hand, inoculating needles range from 12 to 15 cm.

Needles and loops of this length are well suited for use in sophisticated microbiological research since they are of comfortable length and reduce the risk of contamination by reaching deep into containers. Goods offered by suppliers may come in varied lengths depending on the potential consumers' wants and needs.

Packaging and Sterilization

Inoculating loops and needles have to be sterilized and are to be packed in sterile packages to maintain contamination and to ensure sterility.

For instance, such products are best packed in a single, sealed sterile pouch made of plastic or plastic and paper combined. Gamma irradiation, ethylene oxide exposure, and steam sterilization are among the most common sterilization techniques and methods, typically denoted on the packaging. The date of expiry needs to be well considered to maintain the sterility efficacy of the product.

Material and Durability

Most inoculating loops and needles are made of either high-grade steel or plastic.

Plastic loops are usually easy to handle and very breakable. In contrast, steel needle-loops are flexible, strong, and do not break easily. For any kind of sterilization that involves heat, such as flaming, steel loops, and needles, are best suited.

Proper Storage Conditions

Inoculating loops and needles are generally very precious items in microbiological laboratories, and they deserve proper storage to maintain their efficacy.

Store them in climates that are low in humidity. In addition, exposure to moisture can lead to a process known as 'corrosion' where steel inoculating loops are housed. Inoculating loops and needles should be contained in appropriate boxes or receptacles before being offered to the consumer to minimize damage and contamination.

Regular Inventory Checks

As is the case with all disposable inoculating instruments, it is very critical to monitor consumable items at all times.

The expiration date of these products cannot be overlooked if we are to ensure viability. Make use of products whose shelf life has expired poses a threat to contamination and may result in unsuccessful bacterial isolations. Labs should make it a habit to periodically check their stocks and ensure that products are neither sterile nor have expired.

Hygiene Procedures during Handling

If sterilized and disposable inoculating tools are properly handled, it guarantees effectiveness and against offending microorganisms.

To avoid contamination of the culture or the medium, it is advisable to use the tools after they have been exposed to the flame to sterilize them. Whenever the loop or needle is applied, it should be given at least a few seconds of cooling. This is done to avoid burning the bacteria or the culture you will be transferring. The best way to prevent bacterial contamination is by observing proper hygiene protocols whenever handling these items.

No Maintenance for Reusable Sterilized Models

Steel inoculating loops and needles are sometimes designed to be reused throughout a process of sterilization by a flame or through high heat.

Although this kind of instrument has to be monitored and maintained, disposable loops do not. Users should be concerned about the quality of the instruments and the state of sterilization at the beginning of each use, which is critical to ensuring safety in the laboratory.

A1.Most often, inoculating loops and needles for metal work are sterilized using flame.

In the labs, steel loops and needles are usually put over a Bunsen flame to eliminate this microbe. However, loops and needles that are made of plastic are disposable and are already in place sterilized by other means before the user gets them.

A2.Inoculating loops that have not been sterilized will transfer pathogens from one microbiological sample to another.

This may result in mistaken identification of organisms, creation of disease-causing organisms, and contamination of laboratory artifacts. For this reason, always sterilizing the loop is very essential to maintain the integrity of cultures and protect public health in general.

A3.Instructions on the frequency of changing the inoculating needle vary from one lab to another and depend a lot on the volume and sort of work done.

Still, every time the needle is used for making a transfer or an inoculation, it is best practice to change it. This will help minimize contamination and maximize accuracy in the culture practices undertaken in laboratories.

A4.Most importantly, disposable inoculating loops are already sterilized and are highly effective and efficient for their own particular purpose.

However, where sustainability is concerned, inoculating loops that are made of steel and are meant for reuse are more advantageous. In Laboratories where sterilization by fire is practical, steel loops can be reused many times. However, disposables are advantageous when it comes to convenience and reduced contamination potential.

A5.Inoculating loops are made from wire, which is usually treated with steel, while needles usually have steel wire.

Wire is shaped and steel integrated at the tip to make it pointy so as to facilitate transfer. In some instances, like areas that require more economical approaches, plastic is used, which is light but harder than steel.