All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1206 products available)

Several electronic dial weighing scales cater to diverse industrial requirements. These scales rely on electronic sensors to provide precise weight readings on a large visible digital dial. Here's a more in-depth look at some of the more common types.

This scale combines mechanical and electronic elements. It incorporates traditional dial needle movement with an electronic display. The weight indicated on the dial is captured by sensors. It is then converted into an electronic readable format. This type is useful in areas without constant electricity. Its battery-operated feature provides an extended usage period. It also maintains accuracy with the classic dial style for visualists.

A digital electronic dial scale provides a numerical digital readout with dial movement. Most categories of these scales can be linked to computers or data-collection systems. This feature enhances monitoring and records keeping. With various backlit screens, measurements are visible under different lighting situations. This scale provides high accuracy in industrial and commercial settings requiring weight checks. Consistent calibrations are crucial because of their sensitivity.

These scales accommodate substantial loads. They are suited for freight and heavy material weighing in warehouses. The dial and platform are often larger for visibility and practicality. These scales are built sturdily to take on heavy weights without compromising accuracy. They may differ in size and construction for particular business activities.

As the name suggests, these scales are best fitted for lighter items. This scale is perfect for small goods and chemicals in precise measurements. While they can measure less weight than heavy-duty models, their accuracy is still impeccable. They are also vital to industries that deal with smaller packages when weight precision is urgently needed.

The basic structure and components of heavy-duty and electronic dial weighing scales are defined and clarified below. They help in making systematic, logical, and weighty decisions as far as the choice of electronic dial scales is concerned.

BBased on what has been said so far, heavy-duty electronic dial weighing scales are manufactured using good-quality materials. Steel and reinforced plastics are standard materials used. Such manufacturing materials provide strength and durability. Since most of these products are expected to last longer under strenuous conditions, employing quality materials will reduce wear and tear.

They incorporate larger and stronger load cells to handle increased weights. Load cells convert the force exerted by the weight into measurable electrical signals. This signifies that the cells have to be constructed with a more robust material and a brighter design to avoid distortion or damage under heavy load.

Sensitivity to environmental changes often affects functioning scales. However, this is inconsequential with heavy-duty models because they come with compensation features. They stabilize readings despite temperature variations, vibrations, or humidity. Accuracy at high capacitance is important to many industries – such as shipping and logistics.

The platform on these scales is much better compared to ordinary ones. It's constructed larger to accommodate heavy and oversized items during weighing. The platform's height is also engineered to ease the loading and unloading process.

Many heavy-duty scales feature protective ratings such as IP65 or IP67. These ratings guard against water and dust penetration. This is especially essential in outdoor or industrial settings where exposure to the elements is inevitable. The presence of sealing on the scale helps in eliminating the chances of internal damage.

In the case of heavy loads, the measuring activity of the weight may affect the signals from the load cells. To mitigate this challenge, heavy-duty weighing scales come with improved signal processors or amplifiers. Less noisy and more sensitive to weak signals, these devices help keep the measuring system accurate and more effective.

Electronic dial scales are important instruments in businesses due to their effectiveness, accuracy, and ease of use. A thorough understanding of their commercial value and functions is essential to justify their continued use in various industries.

As has been stated, the greatest merit of an electronic dial weighing scale is accuracy. The systems can provide results on a decimal basis within minor weight ranges and sometimes go up to several tons. This degree of accuracy guarantees that commodities are weighed precisely, thus averting wastes, legal issues, and customer dissatisfaction. Also, the scales come with advanced sensors, which enhance consistency. This implies that each measurement is automatically repeated with similar results, eliminating the margin of error common with mechanical scales.

In commercial sectors, speed is vital. This is because, with automation, data collection and display speed increase, weighing gets faster. Moreover, in businesses such as logistics or food production, weight measurements are very important. In these cases, the measurements should be sorted out quickly to process the items. Quick output allows companies to optimize operations, thereby increasing productivity.

Another reason that makes electronic scales more beneficial in business is that many of them can be conveniently connected to other devices for a seamless flow of data. Businesses argue that such a feature enables real-time monitoring and recording of weight. Doing so ensures accuracy and ready access to critical operational data. The data may also be stored and analyzed to determine trends and make timely decisions. The systems are often integrated with inventory management and shipment systems to enhance overall operational effectiveness.

Electronic weighing scales have numerous applications and thus are suitable for several industries. They are implemented in factories to measure raw materials, final products, etc. In freight companies, they weigh trucks to optimize load distribution and comply with legal weight limits. Basically, they can be used anywhere precision in measuring weight is required to achieve optimum results.

Electronic scales are more advantageous due to their unique features for promoting easy use and care. Examples of such features are LCD dials. The dials ensure readings are visible in all environments. Many scales have touchpad controls. This allows easy adjustment and transfer of weights. In addition, the models are designed with simple cleaning and maintenance to avoid wastage of time and effort.

Several factors should be considered to choose the right electronic dial weighing scale. The following are the key factors that should never be neglected.

The electronic dial scale should be capable of withstanding the desired load within the jurisdiction of the concerned industry. For instance, a scale intended for low-capacity weighing would not work for high-capacity weighing and would, therefore, need a scale for that purpose. In Choosing the ideal scale is simple: ask yourself, what is the maximum weight that I will have to weigh?

Scales come in handy when they provide the correct measurements. This means that, fundamentally, the accuracy of the scale is one of the most challenging factors when purchasing one. In general, more advanced technologies give out better accuracy. The sensitivity of the scale is also relevant because, at times, the slightest change in weight makes all the difference. This is especially true in the chemical and laboratory sectors.

As earlier mentioned, the platform platform could affect the functionality of the scale. This means that one should purchase a scale with a platform size that would allow the user to weigh items comfortably without making them overcrowded or hanging off the edges. If the enterprise deals with large products, then perhaps the dial scale with the larger platform is the ideal one.

Another relevant consideration for choosing an electronic dial scale is whether or not it can withstand the working environment it will be put in. One should always seek protection-sealed scales. Protective sealed scales have a typical rating of IP65 or higher. These are helpful in the presence of dust and water, as well as extreme temperatures. They prevent damage to the equipment and ensure accuracy.

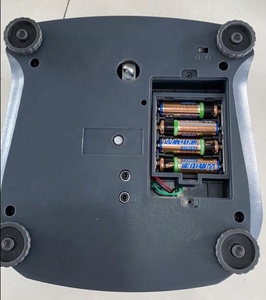

Primarily, electronic dial weighing scales can either be plugged in directly or powered by batteries. The second type is more favorable in spaces where electrical outlets are obsolete. On the other hand, scales that are plugged in provide more constant power in an environment where the scales will always be used. One should also consider the battery life when using battery-operated models. Scales whose battery drains fast can be quite frustrating, more so at critical moments.

Many electronic dial scales have features that promote easy operation. For instance, the keypad controls and the backlit dial enhance visibility. So, to select a scale, this factor should be of utmost importance. The display should be readable so the results can be seen easily. This ensures that the results will be observed and noted without much effort and stressing. Also, the controls should be relatively easy to manage. It gives rise to efficient management.