Popular in your industry

Related Searches:

Top categories

About glass laser engraving

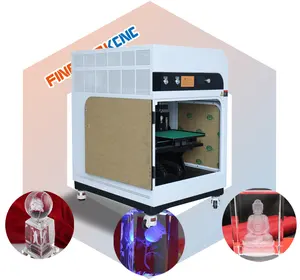

Introduction to Glass Laser Engraving

Glass laser engraving is a cutting-edge technology that allows for precise and intricate designs to be etched onto glass surfaces. This process involves using a high-powered laser beam to engrave patterns, logos, text, or images onto glass items, creating a permanent and elegant finish. Glass laser engraving is widely used in various industries, including the manufacturing of glassware, awards, trophies, decorative items, and promotional products.

Technical Specifications for Glass Laser Engraving

When it comes to glass laser engraving, several technical specifications are crucial to achieving optimal results. The power capability of the laser engraving machine plays a significant role in determining the speed and depth of the engraving. Additionally, the resolution of the laser beam, measured in dots per inch (DPI), determines the level of detail that can be achieved in the engraving. The type of laser used, such as CO2 or fiber laser, also impacts the engraving quality and efficiency.

Applications of Glass Laser Engraving

One of the primary applications of glass laser engraving is in the production of custom glassware, such as wine glasses, tumblers, and vases. By engraving company logos, personalized messages, or intricate designs onto glassware, businesses can create unique and memorable products for their customers. Glass laser engraving is also commonly used in the creation of promotional items, corporate gifts, and awards to add a touch of sophistication and personalization.

Benefits of Glass Laser Engraving

There are several benefits to choosing glass laser engraving for your customization needs. Firstly, laser engraving offers unparalleled precision, allowing for intricate designs to be etched onto glass surfaces with high accuracy. Additionally, glass laser engraving is a non-contact process, meaning that the surface of the glass remains undamaged during engraving, resulting in a clean and professional finish. Moreover, laser engraved glassware is highly durable and resistant to fading, ensuring long-lasting quality.

Choosing the Right Glass Laser Engraving Machine

When selecting a glass laser engraving machine, several factors should be considered to ensure optimal performance and efficiency. The power output of the laser, the engraving area size, and the compatibility with different types of glass are essential considerations. Additionally, the software compatibility and ease of use of the engraving machine should also be evaluated to streamline the engraving process and maximize productivity.

Maintenance Tips for Glass Laser Engraving Machines

Proper maintenance of glass laser engraving machines is crucial to ensure consistent performance and longevity. Regularly cleaning the laser optics, checking and calibrating the laser power, and ensuring proper ventilation are key maintenance tasks. It is also important to regularly inspect and replace worn parts, such as lenses and mirrors, to maintain the quality of the engraving output. By following a routine maintenance schedule, businesses can prolong the lifespan of their glass laser engraving machines and achieve optimal results.