Popular in your industry

Related Searches:

Top categories

About hot melt glue roller applicator

Introduction to Hot Melt Glue Roller Applicator

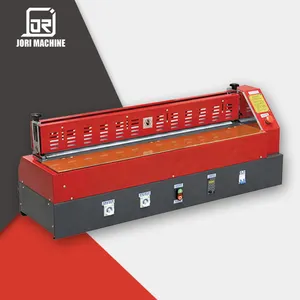

The hot melt glue roller applicator is a versatile and efficient machinery used in various industries for applying hot melt adhesives onto different materials. It consists of a roller mechanism that evenly spreads the adhesive on surfaces, ensuring a strong and durable bond. This equipment plays a crucial role in enhancing production processes by providing a quick and precise adhesive application solution.

Technical Specifications

The hot melt glue roller applicator typically features a robust construction made of high-quality materials to withstand the rigors of industrial applications. It is equipped with a heating element that melts the adhesive, a roller system for application, and temperature control mechanisms to ensure optimal adhesive performance. The machine operates at specific temperature ranges suitable for different types of adhesives and materials, offering flexibility and efficiency in bonding operations.

Design and Functionality

The design of the hot melt glue roller applicator is engineered for precision and reliability. The roller system is designed to apply a uniform layer of adhesive without excess or wastage, contributing to cost efficiency and product quality. The equipment's functionality allows for adjustable speed and pressure settings, enabling users to customize the application process according to their specific requirements.

Features and Advantages

One of the key features of the hot melt glue roller applicator is its ability to work with a wide range of adhesive viscosities, making it suitable for various bonding applications. The machine offers consistent and repeatable results, ensuring uniform adhesive distribution for seamless bonding. Additionally, it promotes faster production cycles and improved product quality, making it a valuable asset for manufacturers seeking efficiency and precision in their processes.

Applications and Industries

The hot melt glue roller applicator finds applications across multiple industries, including packaging, woodworking, automotive, textiles, and more. In the packaging sector, it is used for sealing cartons and boxes, while in woodworking, it aids in edge banding and laminating operations. The equipment's versatility makes it a popular choice for businesses looking to streamline their adhesive application processes.

Choosing the Right Hot Melt Glue Roller Applicator

When selecting a hot melt glue roller applicator for your business, consider factors such as the machine's capacity, speed, and compatibility with your adhesive requirements. Assess the size of your production line, the types of materials you work with, and the desired output quality to determine the most suitable applicator for your operations. It is advisable to consult with industry experts or suppliers to ensure you choose a machine that meets your specific needs.

Maintenance and Care Tips

To ensure the optimal performance and longevity of your hot melt glue roller applicator, regular maintenance is essential. Cleaning the machine regularly to remove any adhesive residue, checking and replacing worn-out parts, and calibrating temperature settings are crucial maintenance tasks. Proper care and maintenance not only prolong the equipment's lifespan but also contribute to consistent and reliable adhesive application results.

Investing in a high-quality hot melt glue roller applicator can significantly enhance your production processes by providing efficient and precise adhesive application solutions. Whether you are in the packaging, woodworking, or automotive industry, this versatile machinery can help streamline your operations and improve product quality. Consider the technical specifications, design features, and compatibility with your specific requirements when choosing a hot melt glue roller applicator for your business.