All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(5 products available)

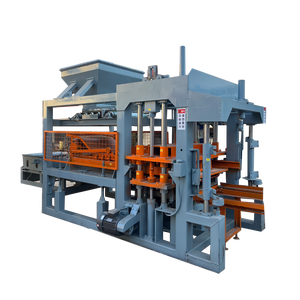

The Hydraform block machine QT6 15 is a versatile piece of machinery primarily used in the construction industry to manufacture blocks for building purposes. In addition to producing standard blocks, it is capable of making a wide range of block types to suit different construction needs. The table shows some advantages of the Hydraform block machine.

The QT6-15 hydraform machine has many applications in the construction industry because it efficiently produces quality blocks from diverse raw materials. These blocks are used in various construction projects.

Residential Buildings

It is possible to use hydraform blocks made by an QT6-15 machine to construct housing projects like single-family homes, multi-family units, and affordable housing developments. The blocks are cost-effective for constructing houses with load-bearing walls, internal partitions, and external walls.

Commercial Buildings

Commercial structures like offices, shopping malls, hotels, and industrial facilities can be constructed with blocks made by the QT6-15 machine. The interlocking blocks will create strong, efficient, and well-utilized commercial spaces.

Institutional Buildings

Some institutional buildings that can use hydraform blocks made by the QT6-15 block machine are schools, universities, hospitals, prisons, and government facilities. The hydraform blocks will provide long-lasting, secure, and functional institutional buildings.

Green Buildings

An environmentally friendly building project can use an interlocking hydraform block as one of the sustainable construction materials. Such green projects include eco-friendly homes, LEED-certified commercial buildings, and zero-energy developments.

Infrastructure Projects

Infrastructure projects that can use hydraform blocks, made with the QT6-15 block machine, include tunnels, retaining walls, dams, and water treatment facilities. The hydraform blocks are ideal for confining structures, drainage channels, and craggy slope stabilization projects.

Vacant Land Development

The QT6-15 hydraform block machine can be used in land development projects where people want to improve the value of their land by creating infrastructural facilities. Some of the sought-after facilities include commercial centers, residential areas, and recreational areas.

The following tips can help adjust the capacity, control system, and other machine features before selecting a proper hydraform block machine:

Production capacity

Before selecting the machine, it's helpful to calculate the required production capacity for creating blocks. There is a range of block machine capacities, from small to large. The ideal production capacity is the one that aligns with what users need and has a great potential market demand.

Energy efficiency

It is essential to consider the machine's energy efficiency and how economical it will be. No one wants to face high energy costs. Also, think about the environmental impact. Selecting an energy-efficient machine can help reduce costs and support a greener environment.

Control system

The machine's control system plays a vital role in its operation. The choice is between manual, semi-automatic, or fully automatic. An automatic control system may ease the operational need and influence the required workforce, yet it might come at a higher cost. So, before making a decision, it's important to consider how many operators there are and their skill levels.

Mobility

For those who need an easy-to-move machine, it's a good idea to check its weight and size. Consider the machine's portability and how simple it will be to shift.

Q1: What does hydraform block machine qt6 15 make?

A1: The QT6-15 hydraform block machine can produce different types of cement products, such as hollow blocks, solid blocks, interlocking blocks, and paver blocks.

Q2: How does the hydraform block machine work?

A2: The machine has a feeding system, a main power system, a vibrating table, and a carrying system. First, the raw material is fed into the mold. Then, the main power system drives the pistons to apply pressure to the material and shapes it into a block. The vibration of the vibrating table helps to consolidate the material and eliminates air pockets. Finally, the molded block is carried out of the machine by the carrying system.

Q3: What is the driving force of the hydraform block machine?

A3: The machine can be driven by electricity, diesel, or hydraulic pressure, depending on the model and specifications.

Q4: Are the blocks produced by the hydraform block machine burnt?

A4: No, the blocks are not burnt. They are air cured after they are formed under pressure in the block-making machine.