All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(984 products available)

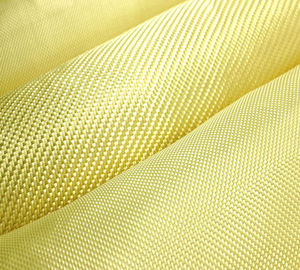

Kevlar mesh net comes in diverse varieties, each tailored for distinct usage necessitates. Here is a rundown of the prevalent types.

The ballistic Kevlar mesh is primarily intended for protective purposes. Usually, it is applied in the manufacture of body armor, vehicle armor, and even protective helmets. Also, the tough fabric is constructed to diffuse and absorb energy, thus enhancing protection against ballistic threats. Additionally, the lightweight nature of the material promotes easy wear for extended durations without discomfort.

This net incorporates the strength and durability of Kevlar into fishing equipment. Normally, it is designed to withstand sharp hooks, rocky and wet terrains, and diverse aquatic environments. This results in nets that are resistant to tearing and fraying. Hence, it makes them outstanding for both commercial and recreational fishing. Furthermore, the nets are lightweight, yet exceptionally strong, promoting easy handling.

The utility mesh serves a broad spectrum of applications where strength and durability are indispensable. Commonly, it includes protective coverings, industrial frameworks, and reinforcement for other materials. Note that this adaptable mesh can be customized to meet diverse width, length, and gauge requirements. Therefore, making it appropriate for specialized tasks. Also, its resistance to chemicals and abrasion guarantees its long-lasting performance in arduous environments.

This particular mesh is designed for heavy-duty applications. Usually, it is constructed to endure extremely high-stress situations and, therefore, is fit for use in such rigorous environments as military operations. The “50Cal” in its name ideally signifies its capability to withstand bullets from a .50 caliber firearm, accommodating any critical protective requirements. More importantly, its unmatched durability supersedes that of many conventional meshes.

This cloth is specially tailored for angling enthusiasts. Conventionally, it integrates the unparalleled strength of the rough textured mesh with the intricacies of fishing practices. The unique interweaving of fibers produces a material boasting high tensile strength while remaining thin and lightweight. Thus, making it adaptable for diverse types of fishing.

The standout features of Kevlar netting setting it apart from other synthetic fibers are its characteristic strength and resilience.

Replacing a Kevlar mesh net entails several key steps to ensure a proper and efficient exchange.

Kevlar nets are ideal for different applications owing to their strength, durability, and resistance to abrasion. Here are several key factors for buyers to consider when purchasing.

The gauge of the netting significantly affects the net's strength and flexibility. Normally, nets with larger gauge holes are ideal for catching larger fish species. This consideration allows for improved water flow and reduced resistance. On the other hand, smaller gauge nets provide a more secure catch. Also, they are better suited for smaller fish like trout.

The mesh type influences the net's durability and the health of the caught fish. A Kevlar net with a smooth finish typifies minimal damage to the fish's scales and fins. This attribute promotes a safer release after catch. Conversely, a rough or entangled mesh provides better gripping power. Nevertheless, it may affect fish more if they are destined for release.

The hole type plays a crucial role in the net's overall functionality. Generally, kennel nets equipped with larger mesh holes enable faster retrieval of fish. They also help prevent the net from getting clogged with debris. Conversely, finer meshes, though more prone to tangling, guarantee a higher retention rate. This feature makes them suitable for smaller target fish.

Normally, the structural integrity of the Keenot net should be quantified by its resistance to tearing and fraying. Stronger nets preserve their shape and functionality even under rigorous use. Further, look for nets with reinforced edges and double-stitching to ensure longevity, especially in challenging environments.

This is a key consideration when selecting fishing nets. Normally, it ensures the net can support the weight of both the catch and any equipment being used. Also, heavier catches or larger fishing vessels call for nets with higher load-bearing capacities.

Kevlar nets find varying applications across multiple industries due to their exceptional strength and versatility.

Kevlar nets are heavily utilized in the military for purposes of ballistic protection. Normally, they are incorporated into body armor, vehicle shields, and protective cases for equipment. Their ability to absorb and disperse energy, acting as a safeguard against bullets and shrapnel, is invaluable. Further, these nets are lightweight and offer soldiers easy mobility without sacrificing defense.

In sports, Kevlar is commonly used in fishing nets, particularly for freshwater fishing. Normally, its unmatched tensile strength makes the nets resistant to wear, fraying, and even breakage from sharp objects, thus a reliable gear for anglers. Further, in extreme sports like climbing and paragliding, Kevlar nets protect individuals and equipment, reducing risks of injuries or damage.

Kevlar nets serve as crop protection covers, shielding plants from pests, birds, and adverse weather conditions in agriculture. This allows the crops to grow without constant manual supervision or expensive chemical treatments. Additionally, the durable material withstands environmental elements such as sunlight, rain, and wind. This contributes to longer netting life spans.

These nets are applied as reinforcing materials in the aerospace industry. Moreover, the exceptional strength-to-weight ratio of Kevlar enhances the composite structures without adding substantial weight. This improves fuel efficiency for aircraft and spacecraft.

Kevlar nets find application in safety equipment like gloves, harnesses, and fall protection systems. Usually, these nets protect workers from severe injuries when handling sharp tools or working at heights. Further, their tensile strength stands the rigors of industrial work environments. Thus ensuring long-term performance.

Typically, in forensic science, these nets are utilized for crime scene analysis and for the collection of evidence. Normally, their fine mesh prevents the loss of small items while allowing for easy visibility during investigation. Also, the durability of netting ensures they can be used in outdoor environments.

In commercial fishing, Kevlar mesh nets are favored for their durability and resistance to sharp marine life. This allows them to withstand heavy catches and rough seas without significant wear and tear. Further, they ensure sustainable practices owing to their ability to allow juvenile fish to escape through appropriately sized mesh holes.

Normally, Kevlar netting is designed with small, interwoven openings between the fibers. These openings are typically manufactured with a size large enough to enable liquids to pass through easily. Nonetheless, the tightly woven structure is intended to reduce the mesh’s overall permeability by limiting the passage of solid particles through it.

Kevlar nets are suitable for freshwater and saltwater fishing. Their unmatched tensile strength and resistance to fraying allow them to withstand sharp objects, rough terrains, and diverse aquatic environments. They cater to the unique challenges encountered in both settings effectively, thus guaranteeing a durable net.

Kevlar nets have been designed with a smooth, textured surface that minimizes abrasion. Henceforth, they are constructed to prevent harm to animals when used in kennel partitions. Also, these nets are tested to meet rigorous standards for animal welfare. Further, they are distinguished for their durability amid extended use.

Although recycling techniques for Kevlar nets are still in their infancy, these nets can be recycled. Normally, they entail breaking down the fibers to incorporate them in new materials. Moreover, many manufacturers are investigating options for returning or recycling netting to reduce environmental impact.

Usually, store them in a cool, dry location away from direct sunlight. This practice prevents UV degradation and maintains the material’s integrity. Also, avoid folding or creasing the netting. Instead, loosely roll it to prevent fiber kinks.